Fuel supply method for high-pressure natural gas injection engine

a high-pressure natural gas and injection engine technology, which is applied in the direction of machines/engines, container discharging methods, lighting and heating apparatus, etc., can solve the problems of low liquefaction efficiency, flash gas may be generated, low liquefaction efficiency, etc., and achieves a decrease in liquefaction energy, liquefaction energy consumption in reliquefaction, and the effect of increasing the liquefaction point of the bog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

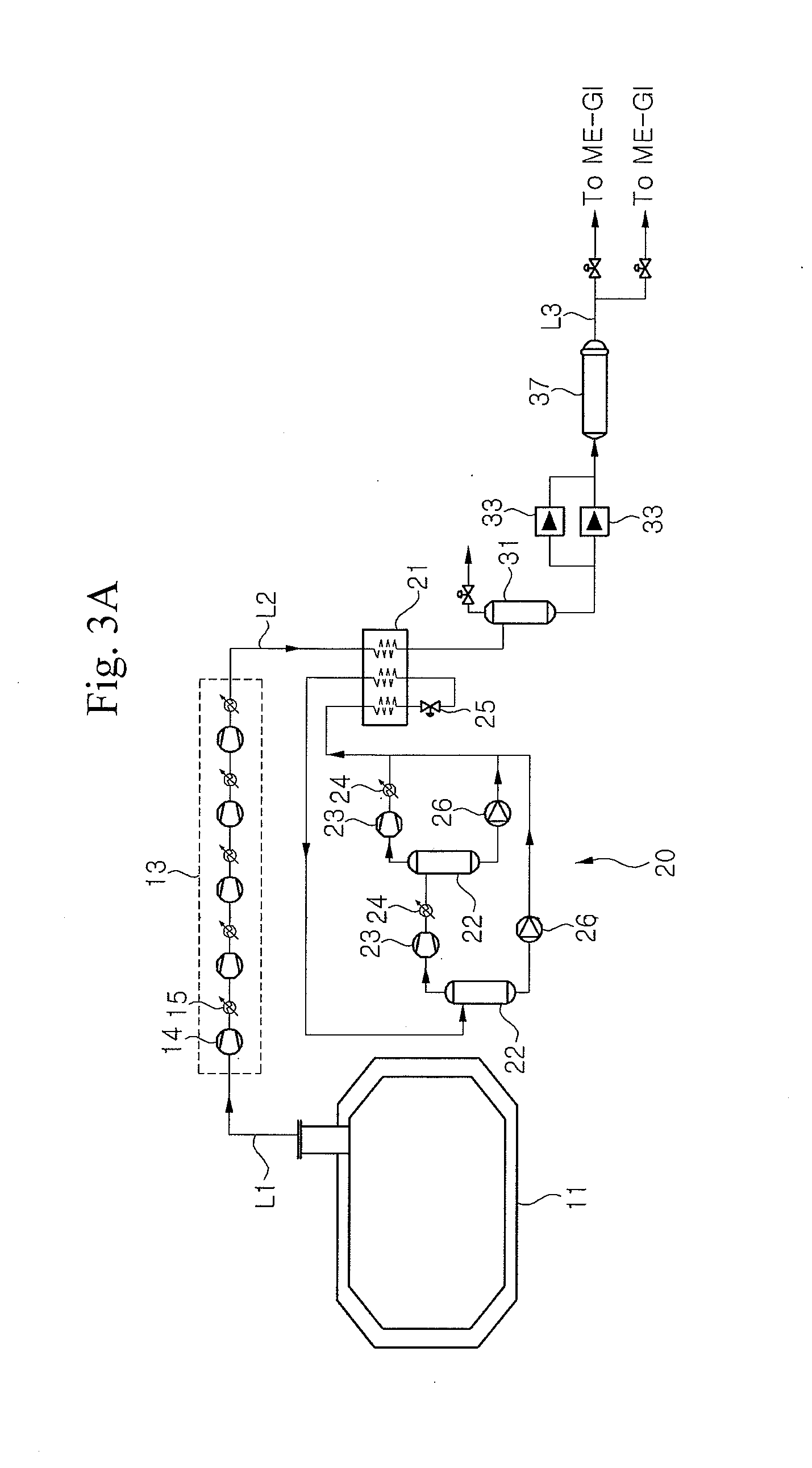

[0070]FIG. 3A is a configuration diagram illustrating a fuel supply system for a marine structure such as an LNG carrier having a high-pressure natural gas injection engine, for example, an ME-GI engine, according to a first embodiment of the present invention. FIG. 3A illustrates an example in which the fuel supply system for the high-pressure natural gas injection engine according to the present invention is applied to the LNG carrier equipped with the ME-GI engine capable of using natural gas as fuel. However, the fuel supply system for the high-pressure natural gas injection engine according to the present invention may also be applied to any type of marine structures equipped with a liquefied gas storage tank. Examples of the marine structures may include vessels, such as an LNG carrier and an LNG RV, and offshore plants, such as an LNG FPSO and an LNG FSRU.

[0071]According to the fuel supply system for the marine structure having the high-pressure natural gas injection engine a...

second embodiment

[0107]FIG. 7A is a configuration diagram illustrating a fuel supply system for a marine structure having a high-pressure natural gas injection engine (e.g., an ME-GI engine) according to a second embodiment of the present invention. The second embodiment illustrated in FIG. 7A is different from the first embodiment only in that before a reliquefaction apparatus reliquefies BOG compressed to a medium pressure, the fuel supply system preheats the compressed BOG by heat exchange with LNG supplied from a high-pressure pump 33 to a high-pressure gasifier 37. Thus, the following description will be focused on the difference from the first embodiment.

[0108]As illustrated in FIG. 7A, the liquefied BOG compressed to a high pressure by a high-pressure pump 33 exchanges heat with the BOG supplied to a reliquefaction apparatus 20, in a heat exchanger 35 before supply to a high-pressure gasifier 37. Since the liquefied BOG supplied to the high-pressure gasifier 37 is lower in temperature than th...

third embodiment

[0115]FIG. 8A is a configuration diagram illustrating a fuel supply system for a marine structure having a high-pressure natural gas injection engine (e.g., an ME-GI engine) according to a third embodiment of the present invention. The third embodiment illustrated in FIG. 8A is different from the first embodiment only in that the fuel supply system preheats BOG before compression. Thus, the following description will be focused on the difference from the first embodiment.

[0116]As illustrated in FIG. 8A, in the fuel supply system for a marine structure having a high-pressure natural gas injection engine according to the third embodiment of the present invention, natural boil-off gas (NBOG) generated and discharged from a liquefied gas storage tank 11 is compressed by a BOG compression unit 13 to a medium pressure of about 12 to 45 bara. The compressed BOG is supplied to a BOG preheater 41 installed at the upstream side of a BOG compression unit 13, before supply to a reliquefaction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com