Acoustic ash removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

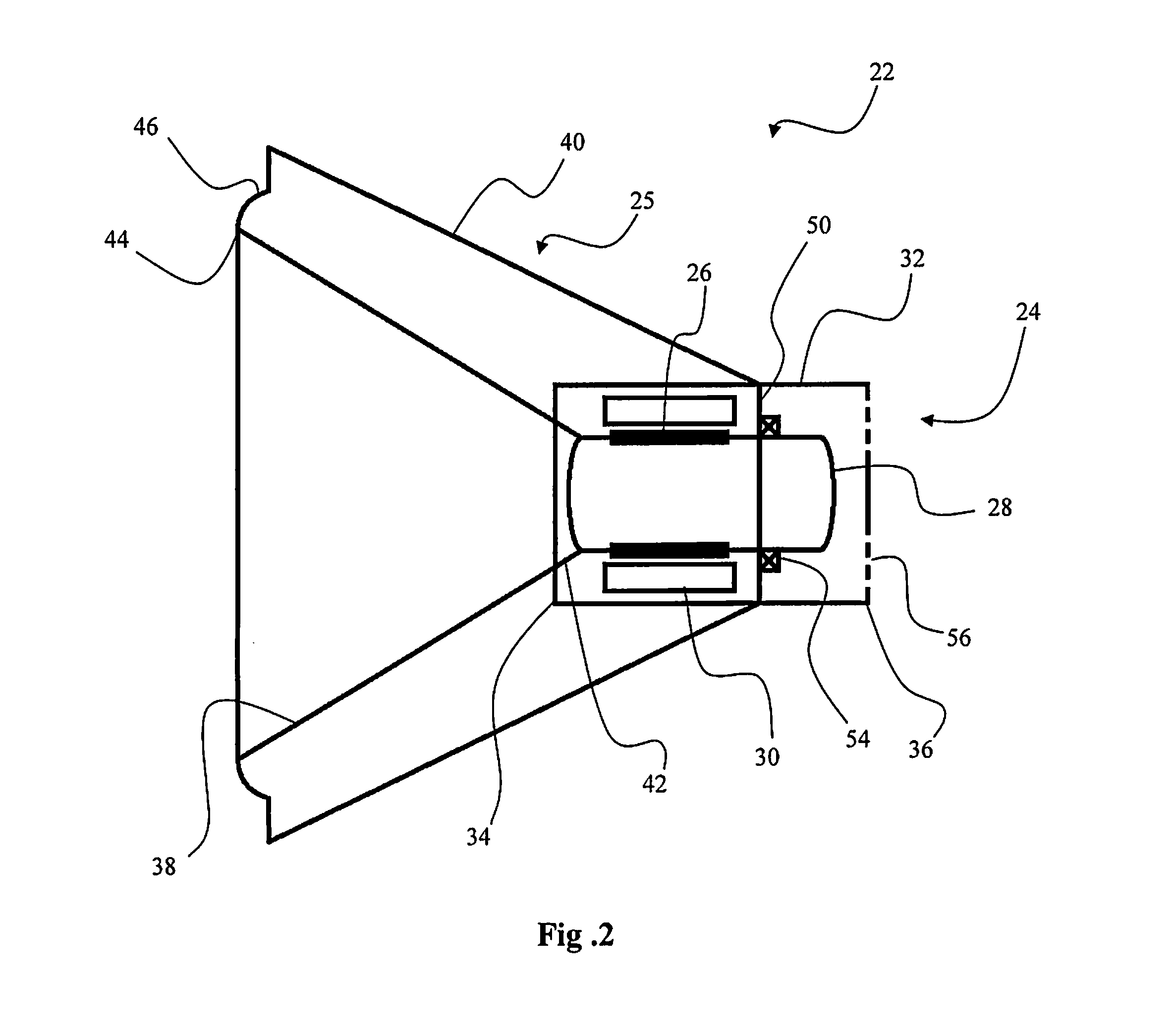

[0032]As depicted in FIG. 2, an acoustic system 20, according to an embodiment of the present invention, comprises at least one speaker 22 having a driver assembly 24 and a cone assembly 25. The driver assembly 24 further comprises a speaker coil 26, a driver 28, a permanent magnet 30 and a driver housing 32. As depicted in FIG. 2, the speaker coil 26 is arranged in a cylindrical coil around the driver 28, wherein the permanent magnet 30 comprises a cylindrical pipe shape encircling the cylindrical speaker coil 26. Alternatively, the permanent magnet 28 can comprise a cylindrical shape extending into the center of the speaker coil 26, wherein the driver 28 defines an inner cavity extending longitudinally through the speaker coil 26. The driver housing 32 comprises a cup shape having an open front end 34 and a closed rear end 36. The cone assembly 26 can comprise a cone 38 and a speaker housing 40. The cone 38 comprises a frustoconical shape having a first end 42 and a second end 44,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com