Thermal de-polymerization process of plastic waste materials

a technology of thermal depolymerization and plastic waste, which is applied in the production of liquid carbonaceous fuels, hydrocarbon oil treatment, liquid hydrocarbon mixtures, etc., can solve the problems of low yield of valuable aromatic and high molecular hydrocarbons, non-uniform fluidized beds, and relatively high technology costs, so as to improve the decomposition of waste plastic materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]Further understanding of the object, construction, characteristics and functions of the invention, a detailed description with reference to the embodiments is given in the following.

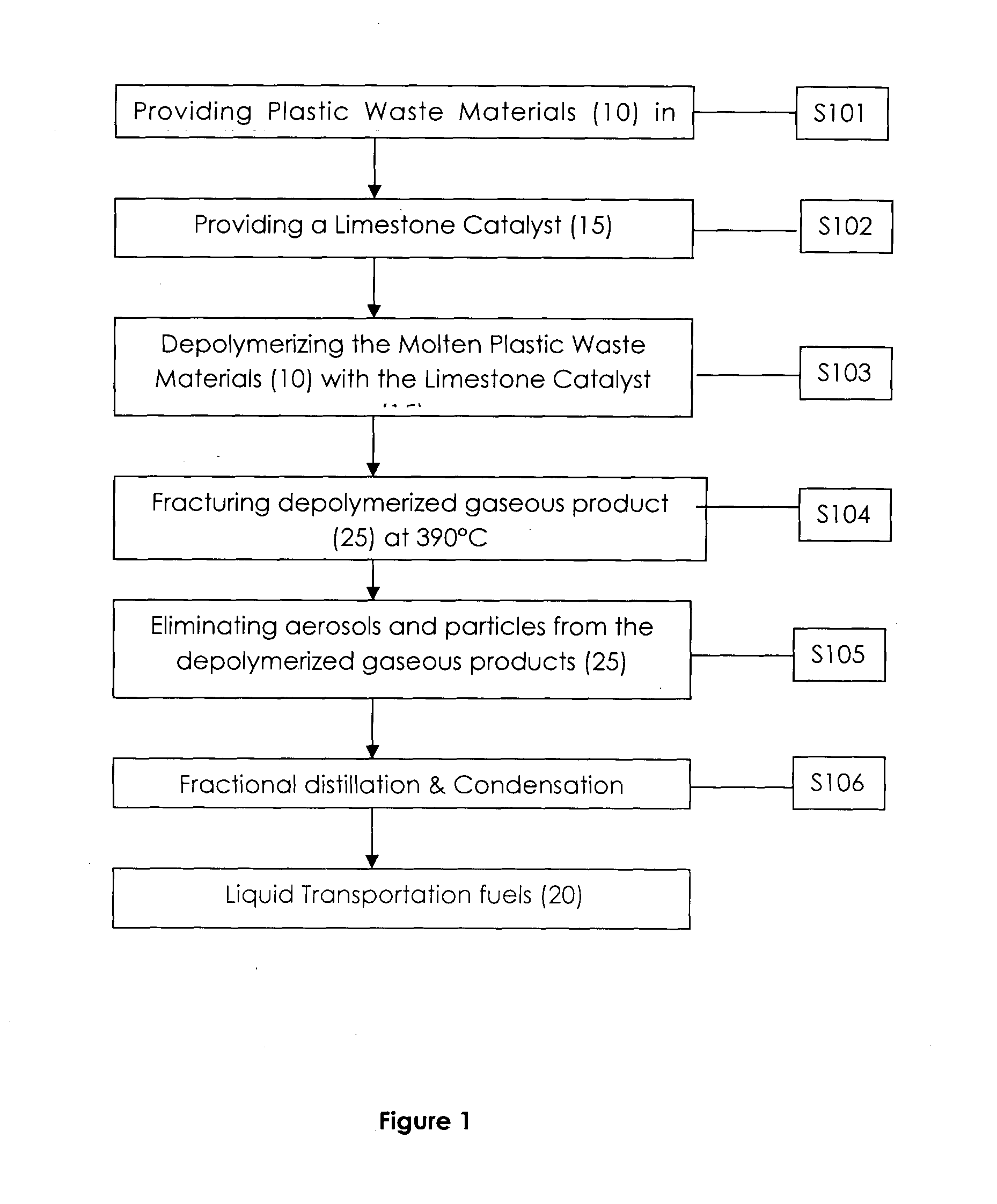

[0015]The present invention relates to a process (100) for thermal depolymerization of waste materials, particularly plastic waste materials (10), into liquid transportation fuel (15) with the use of limestone (20) as a catalyst. The waste plastic materials (10) as described herein referred to municipal and / or industrial wastes made of, include but not limited to, polyethylene, polypropylene and polyvinyl chloride.

[0016]In one embodiment of the present invention, the limestone catalyst (20) is resulted by means of sintering a solid composition comprising aluminum oxide (Al2O3) ranging from 39% to 41%; calcium oxide (CaO) ranging from 30% to 32%; silicone oxide (SiO) ranging from 0.09% to 0.12%; and magnesium oxide ranging from 0.01% to 0.03%. More preferred the solid composition comprises 40.6%±0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com