Marine Engine Lubrication

a technology for marine engines and lubricating fluids, applied in the direction of non-fuel substance addition to fuel, liquid carbonaceous fuels, base materials, etc., can solve the problems of crack formation and propagation through the piston, and crankcase explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0085]The present invention is illustrated by but in no way limited to the following examples.

Components

[0086]The following components were used:

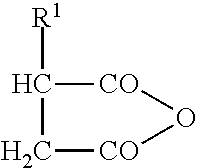

Ester Basestocks (A1)

[0087]a polyol ester (PRIOLUBE® 3970), a trimethylolpropane ester with C8-10 fatty acids, having a viscosity of 4.4 mm2s−1 at 100° C., ex Croda Lubricants;[0088]a polymer ester (KETJENLUBE® 115), in the form of a copolymer of alpha-olefins and a dicarboxylic acid dibutylester with an average molecular weight of approximately 1400.

Basestocks (A2)

[0089]a Group I oil (XOMAPE 600) (for comparison)

[0090]a Group II oil (RLOP 600)

[0091]a Group III oil (YUBASE 8)

[0092]Commercial identifications are in parentheses.

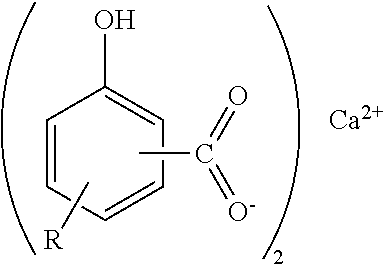

Detergents (B)

[0093]calcium alkyl salicylate (BI 8.0)

[0094]calcium alkyl salicylate (BI 3.0)

Basicity indices are in parentheses.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass % | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com