Combined Heat and Power Technology for Natural Gas Liquefaction Plants

a technology of natural gas liquefaction and heat generation, which is applied in the direction of liquefaction, machines/engines, lighting and heating apparatus, etc., can solve the problems of large synchronous motors, less reliable and demanding more control equipment, and large induction motors that can operate at high speeds, etc., to reduce fuel gas consumption, reduce greenhouse gas emissions, and optimize the overall production facility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

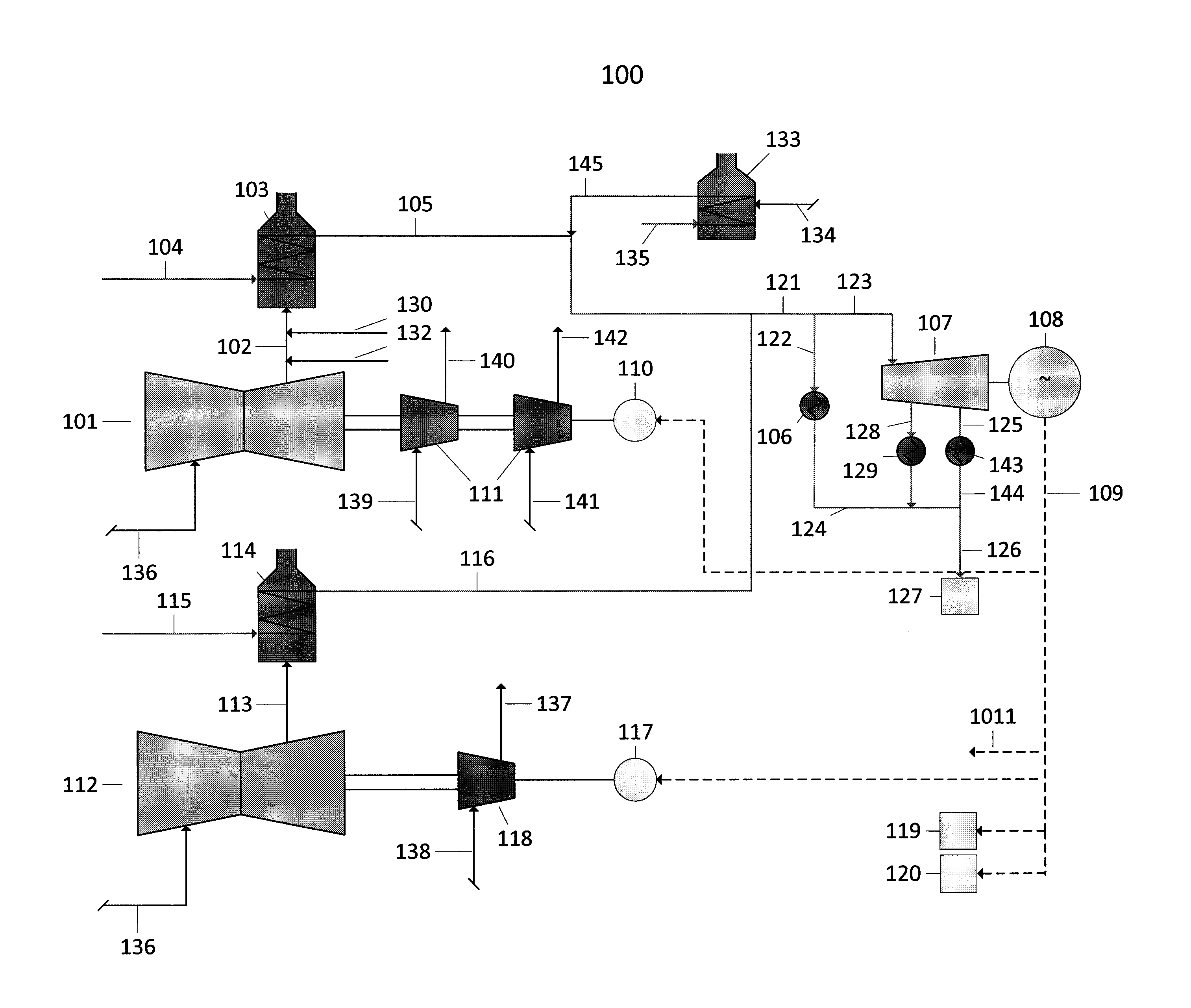

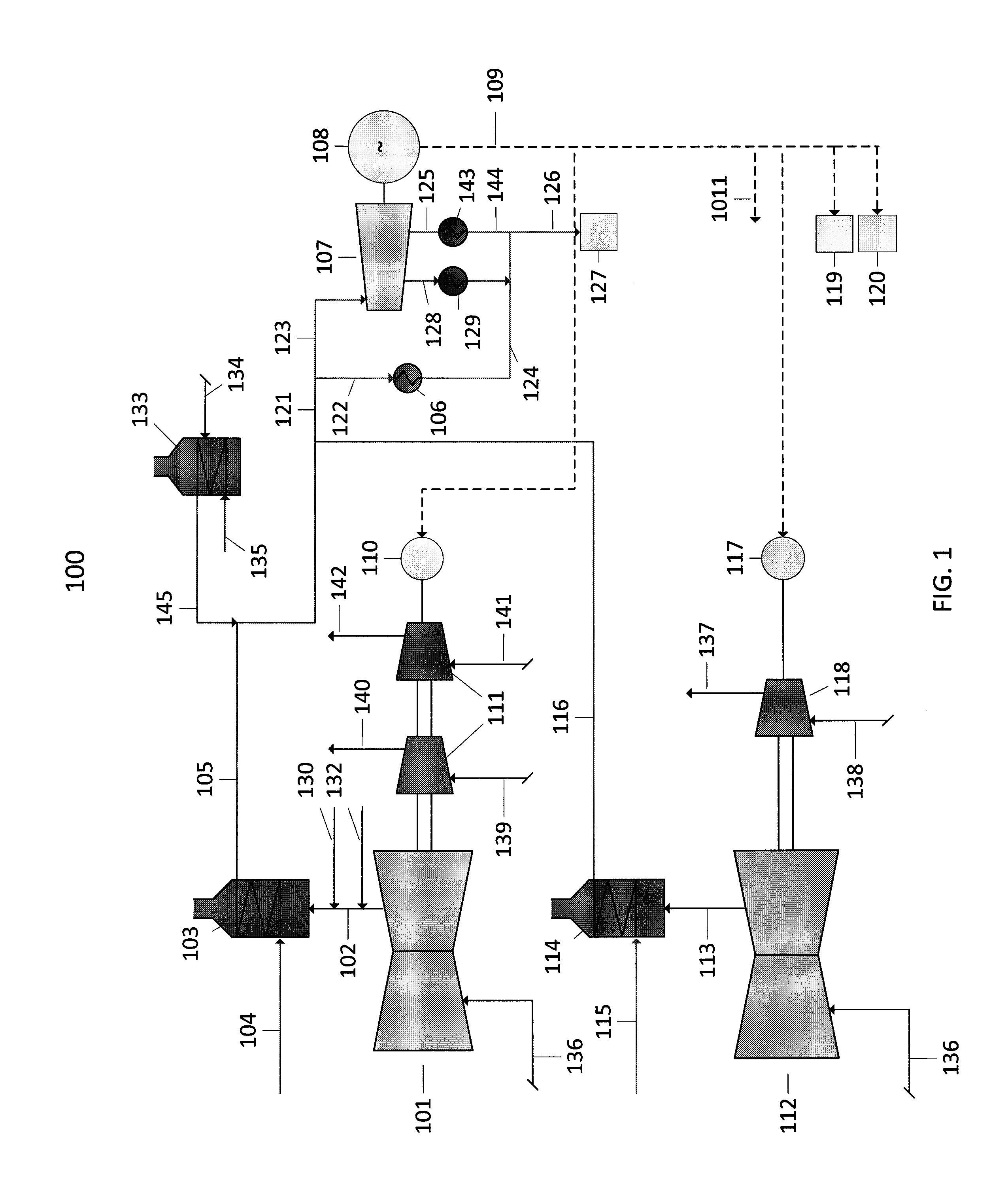

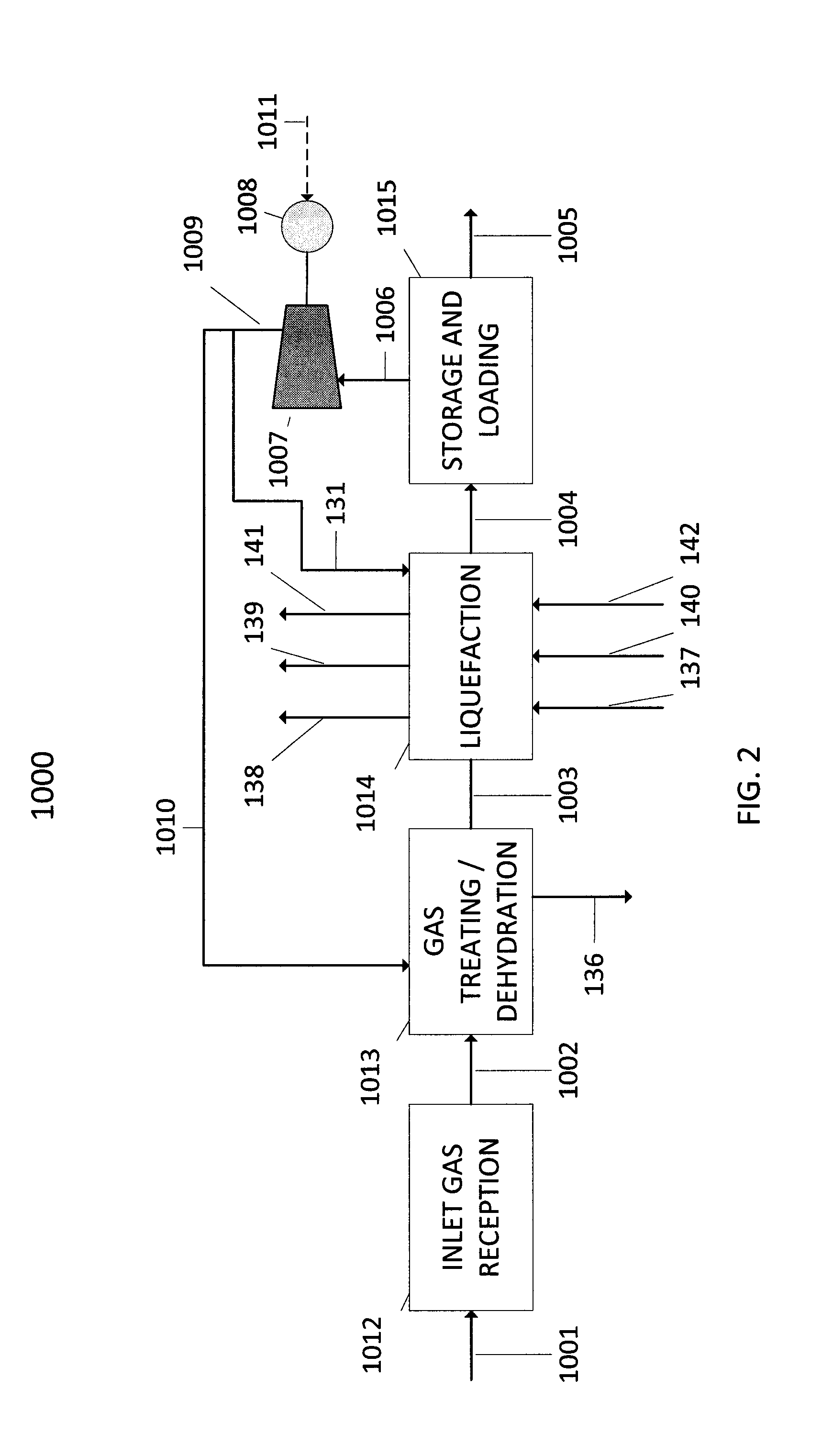

[0026]FIG. 1 is a schematic drawing of a LNG facility waste heat recovery system 100 in accordance with one embodiment of the present invention. Waste heat recovery system 100 comprises a first gas turbine 101 connected to a first plurality of refrigeration compressors 111, although in other embodiments (not shown) the first gas turbine 101 can be connected to a single refrigeration compressor 111. In general refrigeration compressors 111 are rotary type, either centrifugal or axial, although other types and configurations can find utility in further aspects of the present disclosure. The first gas turbine 101 produces hot exhaust gas that travels through a first exhaust line 102 to a first heat recovery steam generator (“HRSG”) 103, which takes boiler feed water from first water line 104 and produces steam that travels through first steam line 105. The HRSG 103 may be installed vertically or horizontally, and may produce steam at one or more pressure levels. The heat recovery devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com