Method and device for manufacturing a three-dimensional object that is suitable for application to microtechnology

a three-dimensional object and manufacturing method technology, applied in the direction of manufacturing tools, auxillary shaping apparatus, additive manufacturing processes, etc., can solve the problems of residual porosity and inability to meet certain applications in the microtechnology field, and achieve the effect of improving mechanical properties of manufactured components and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

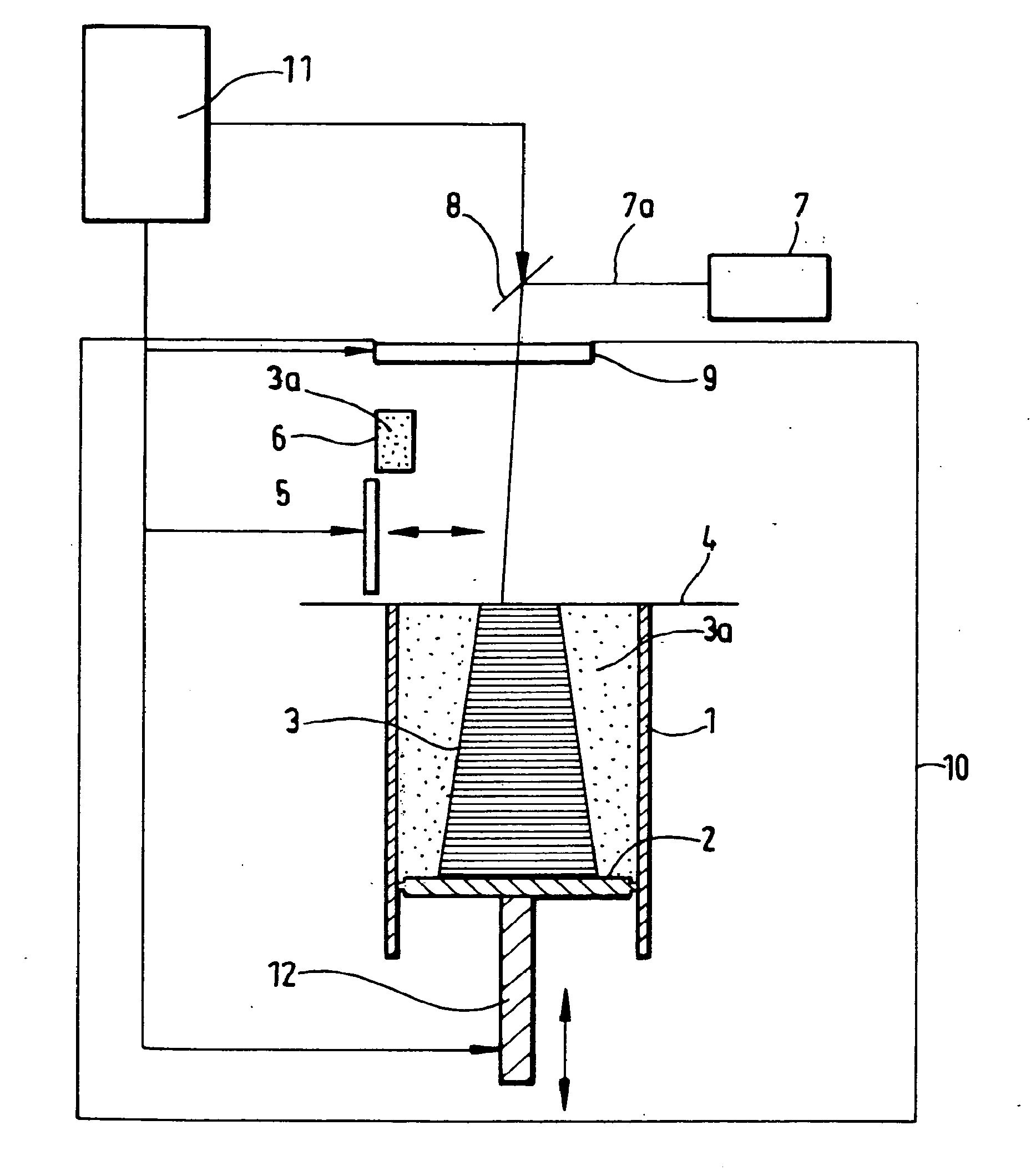

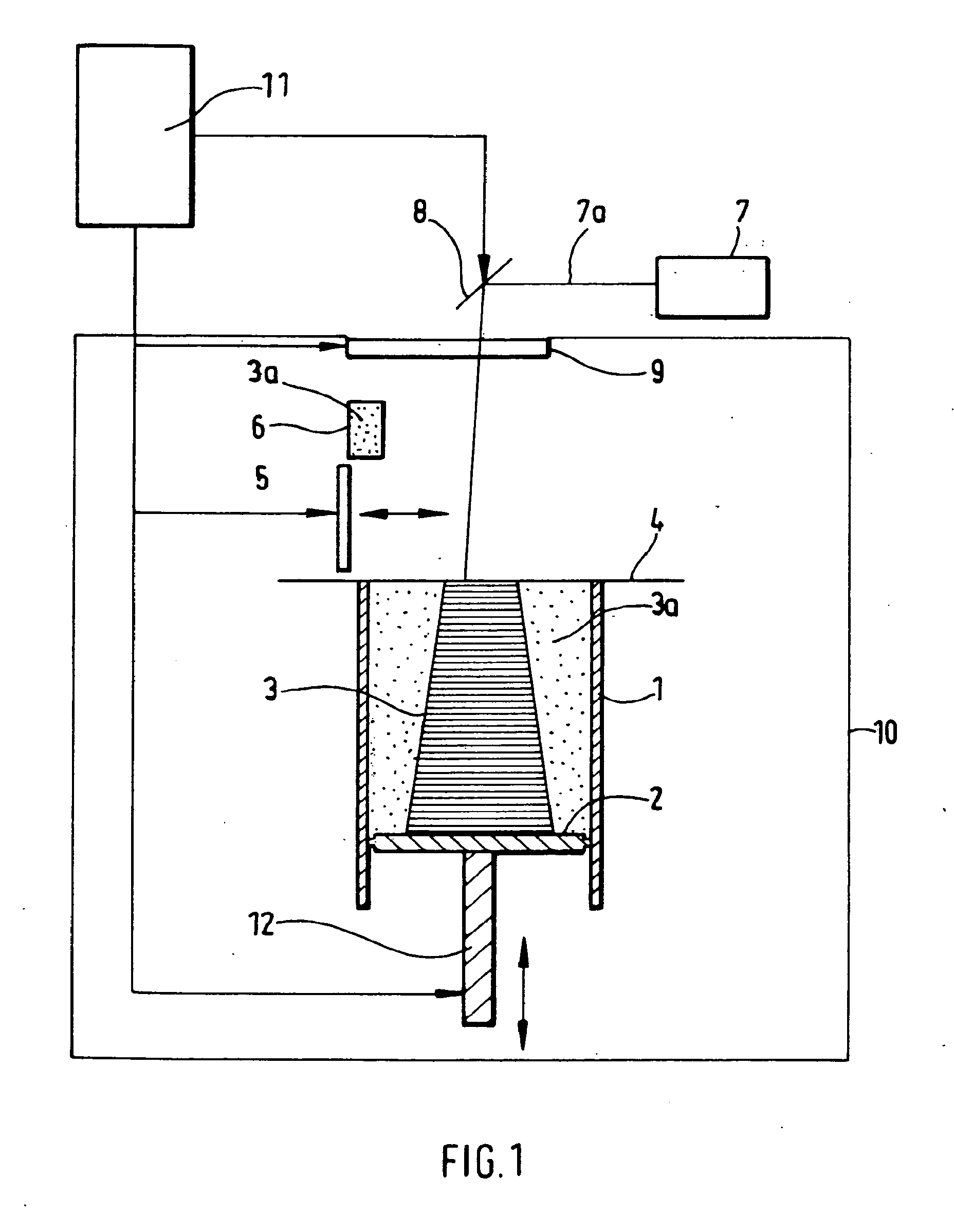

[0013]Referring now to FIG. 1, a laser sintering device comprises a frame 1, which is open towards the top and has a platform 2 arranged therein that is movable in a vertical direction. The platform 2 is adapted to carry the three-dimensional object 3 to be manufactured. The frame 1 and the platform 2 define inside a building space. The platform 2 is connected to a lifting mechanism 12 that moves the platform 2 in a vertical direction so that the layer of the object 3 that is to be solidified is arranged in a working plane 4, respectively.

[0014]Furthermore, a coating device 5 for applying a layer of a powdery building material 3a is provided. Regarding the building material 3a, any laser-sinterable powder or powders may be used, such as polymers, for example, polyamide and / or polystyrene, metals, ceramics, compound materials and in particular high temperature plastics such as for example PAEK (polyaryletherketone). Regarding metal-containing powder material, any metals and their all...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com