Mixed abrasive tungsten cmp composition

a technology of tungsten and tungsten, which is applied in the direction of electrical equipment, chemistry equipment and processes, other chemical processes, etc., can solve the problems of compromising planarity and overall device integrity, degrading electrical performance, and unable to meet local and global planarity requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

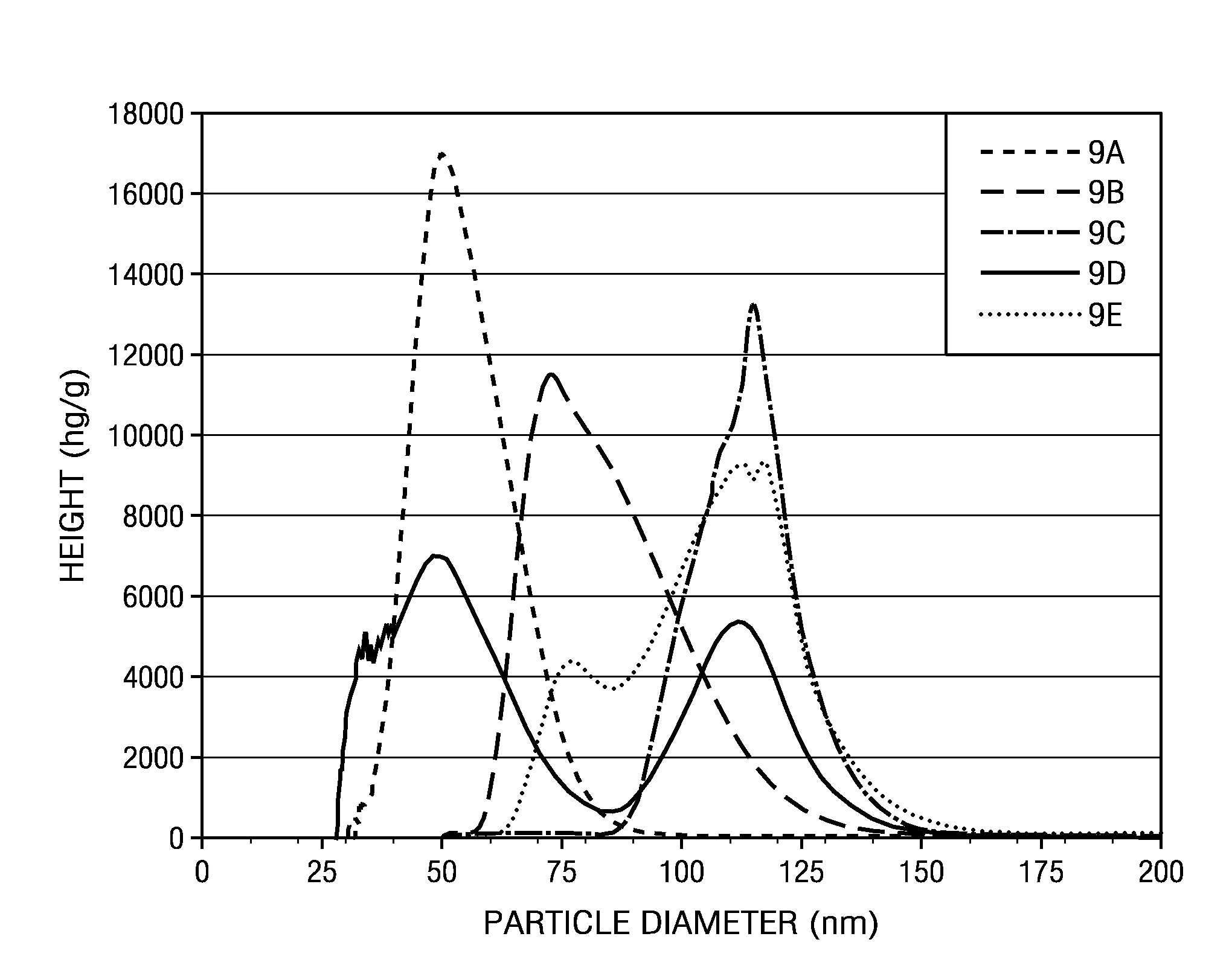

[0056]In the Examples disclosed herein, mixed silica abrasive polishing compositions were prepared using first and second silica abrasives selected from nine silica abrasive dispersions. Dispersions A1, B1, C1, and D1 included colloidal silica dispersions treated with an aminosilane (aminopropyl trialkoxysilane) such that the colloidal silica particles had a permanent positive charge of greater than 10 mV. Dispersions A2, B2, C2, and D2 included colloidal silica particles dispersed in an aqueous solution. The colloidal silica abrasives in A1, A2, B1, B2, C1, C2, D1, and D2 each contained a partially aggregated silica abrasive in which 50 percent or more of the colloidal silica abrasive particles include two aggregated primary particles. Dispersion F2 included an untreated fumed silica having a surface area of about 150 m2 / g which was dispersed in an aqueous solution. Further details regarding these nine silica abrasive dispersions are presented in Table 1. The primary particle sizes...

example 2

[0057]The tungsten (W) polishing rate was evaluated in this example for various polishing compositions, each of which included first and second silica abrasives selected from dispersions A1, B1, C1, and D1 in Example 1. The first and second silica abrasives in this example each included a colloidal silica having a permanent positive charge of greater than 10 mV. This example demonstrates the effects of the relative amounts of the first and second silica abrasives and the particle sizes of the first and second silica abrasives on the W polishing rate. Each of the polishing compositions had a pH of about 2.5 and included 0.031 weight percent ferric nitrate nonahydrate (Fe(NO3)3.9H2O), 0.04 weight percent malonic acid, and 2.4 weight percent hydrogen peroxide. The W polishing rates were obtained by polishing eight inch blanket wafers having a W layer using a Mirra® CMP tool (available from Applied Materials) and an IC1010 polishing pad at down-force of 2.5 psi, a platen speed of 103 rp...

example 3

[0059]The tungsten (W) polishing rate was evaluated in this example for various polishing compositions, each of which included first and second silica abrasives selected from dispersions A1, B1, C1, and D1 in Example 1. The first and second silica abrasives in this example each included a colloidal silica having a permanent positive charge of greater than 10 mV. This example also demonstrates the effects of the relative amounts of the first and second silica abrasives and the particle sizes of the first and second silica abrasives on the W polishing rate. Each of the polishing compositions had a pH of about 2.5 and included 0.031 weight percent ferric nitrate nonahydrate, 0.04 weight percent malonic acid, and 2.4 weight percent hydrogen peroxide. The W polishing rates were obtained by polishing eight inch blanket wafers having a W layer using a Mirra® CMP tool (available from Applied Materials) and an IC1010 polishing pad at down-force of 2.5 psi, a platen speed of 103 rpm, a head s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com