Materials and Methods

a technology of antifouling coatings and materials, applied in the direction of antifouling/underwater paints, pipes, protein coatings, etc., can solve the problems of affecting the performance of antifouling coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

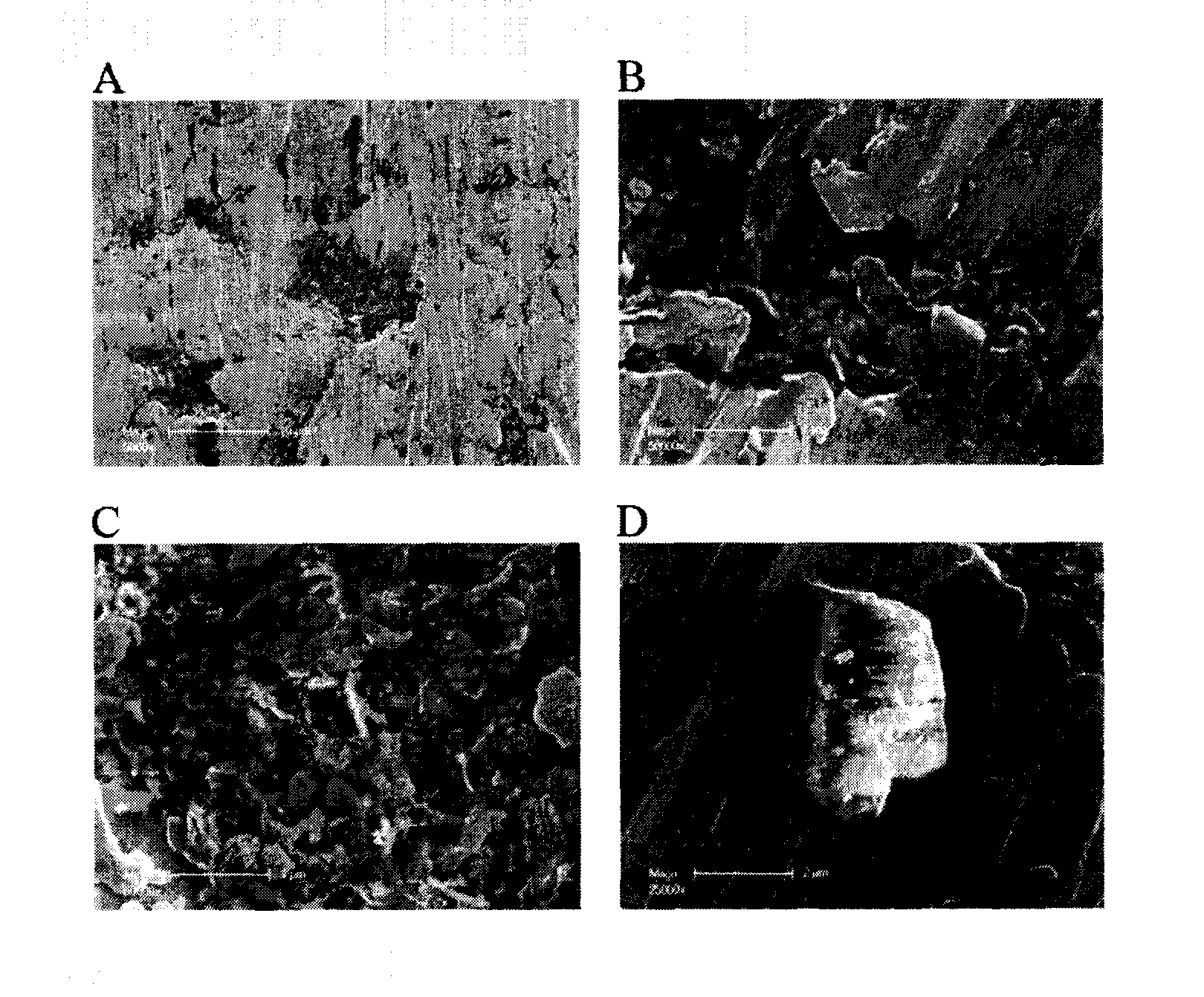

Image

Examples

example 1

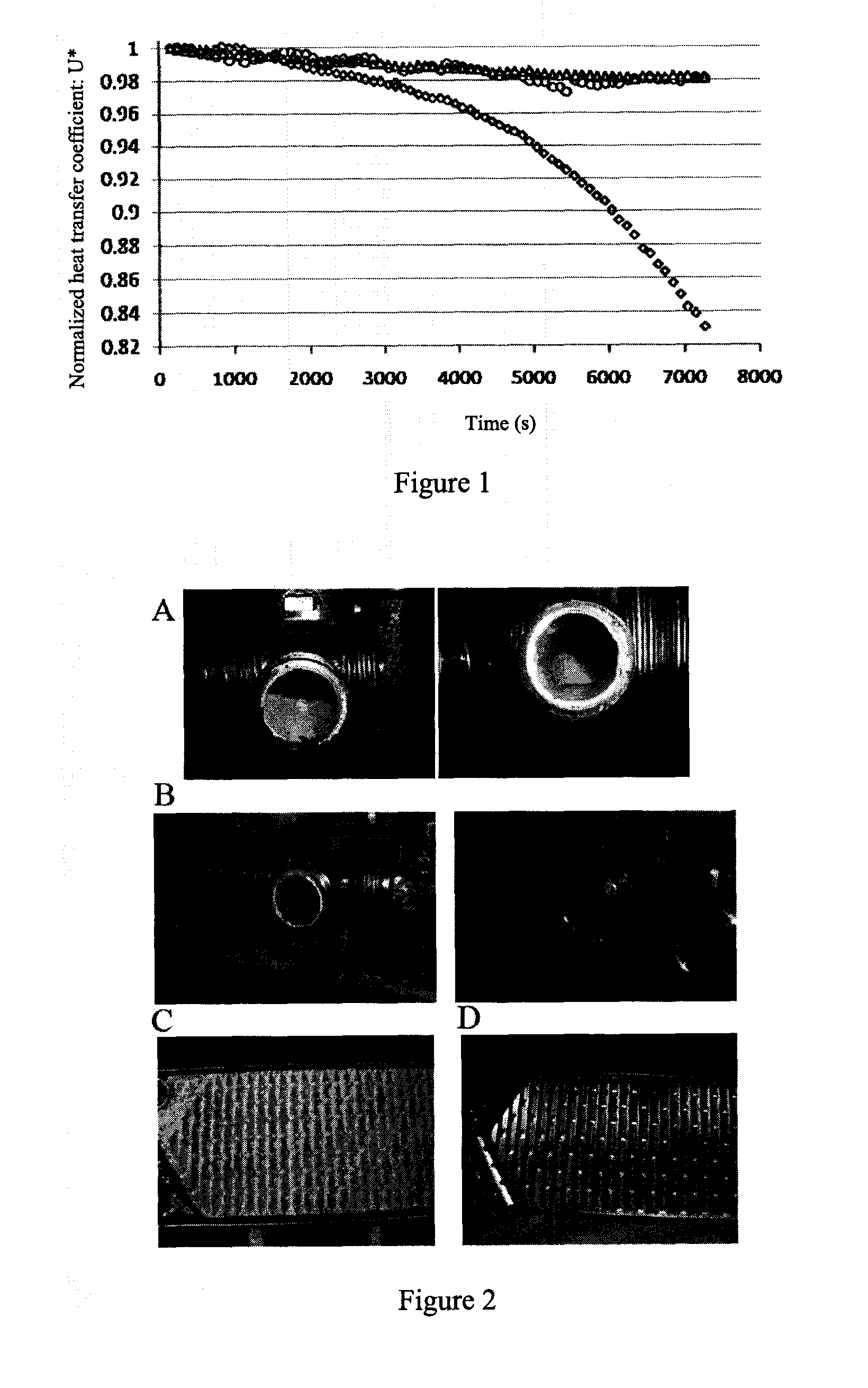

Analysis of Milk Fouling Using a Plate Heat Exchanger as Substrate and Cooling Water Fouling Using a UHT Heat Exchanger as Substrate

[0056]Materials and Methods

[0057]Coating of Substrates

[0058]Polysaccharide (in this case, 35% dextrin starch was mixed with 65% OSA starch and the final concentration of the mixture in water was 8.5% (w / w) with the pH around 3.5) was dissolved in water at 55° C. and heated up to 85° C. Solution was pumped into the heat exchanger and circulated for 4 hours and temperature was kept at 95° C. with the flow rate of 17 L / min for the plate heat exchanger and 35-40 L / min for the UHT heat exchanger. The polysaccharide solution was drained after 4 hours. Protein solution (80% casein (containing calcium) was mixed with 20% whey proteins with the final concentration of 12% (w / w) in water, pH at 6.7) was dissolved below 50° C. and pumped into the heat exchanger with the same flow rate of the polysaccharide solution. Protein solution was circulated for 2 hours at 85...

example 2

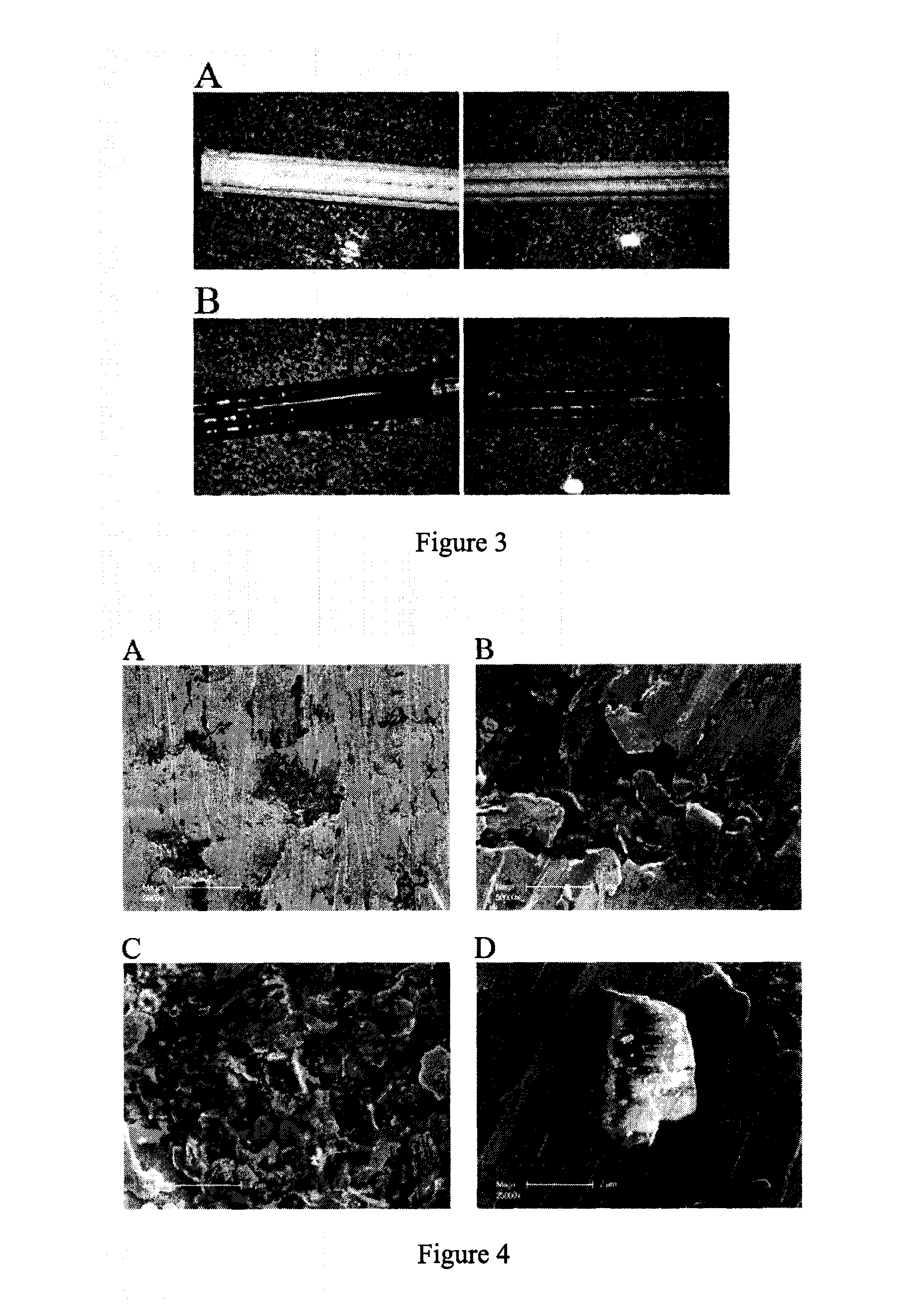

Analysis of Milk Fouling Using a Dairy Processing Production Line as Substrate

[0103]Materials and Methods

[0104]Coating of Substrates

[0105]Polysaccharide (in this case, 35% dextrin starch was mixed with 65% OSA starch and the final concentration of the mixture in water was 9% (w / w) with the pH around 3.5) was dissolved in water at 85° C. Solution was pumped into the heat exchanger and circulated for 5 hours and temperature was kept at 95° C. with the flow rate of 10 L / min for the Amotec-THE heat exchanger and 80 r / min stirring speed for the pot heat exchanger. The polysaccharide solution was drained after 5 hours. Protein solution (80% casein (containing calcium) was mixed with 20% whey proteins with the final concentration of 12% (w / w) in water, pH at 6.7) was dissolved below 50° C. and pumped into the heat exchanger with the same flow rate and stirring speed of the polysaccharide solution. Protein solution was circulated for 1 hour at 90° C. The protein solution was then drained an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com