Electromagnetic wave absorbing sheet and method of manufacturing the same and electronic device using the same

a technology of electromagnetic wave absorbing sheet and manufacturing method, applied in the direction of shielding materials, paper/cardboard containers, instruments, etc., can solve problems affecting adjacent other circuit elements, and achieve the effects of excellent electromagnetic wave absorbing rate, high productivity, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

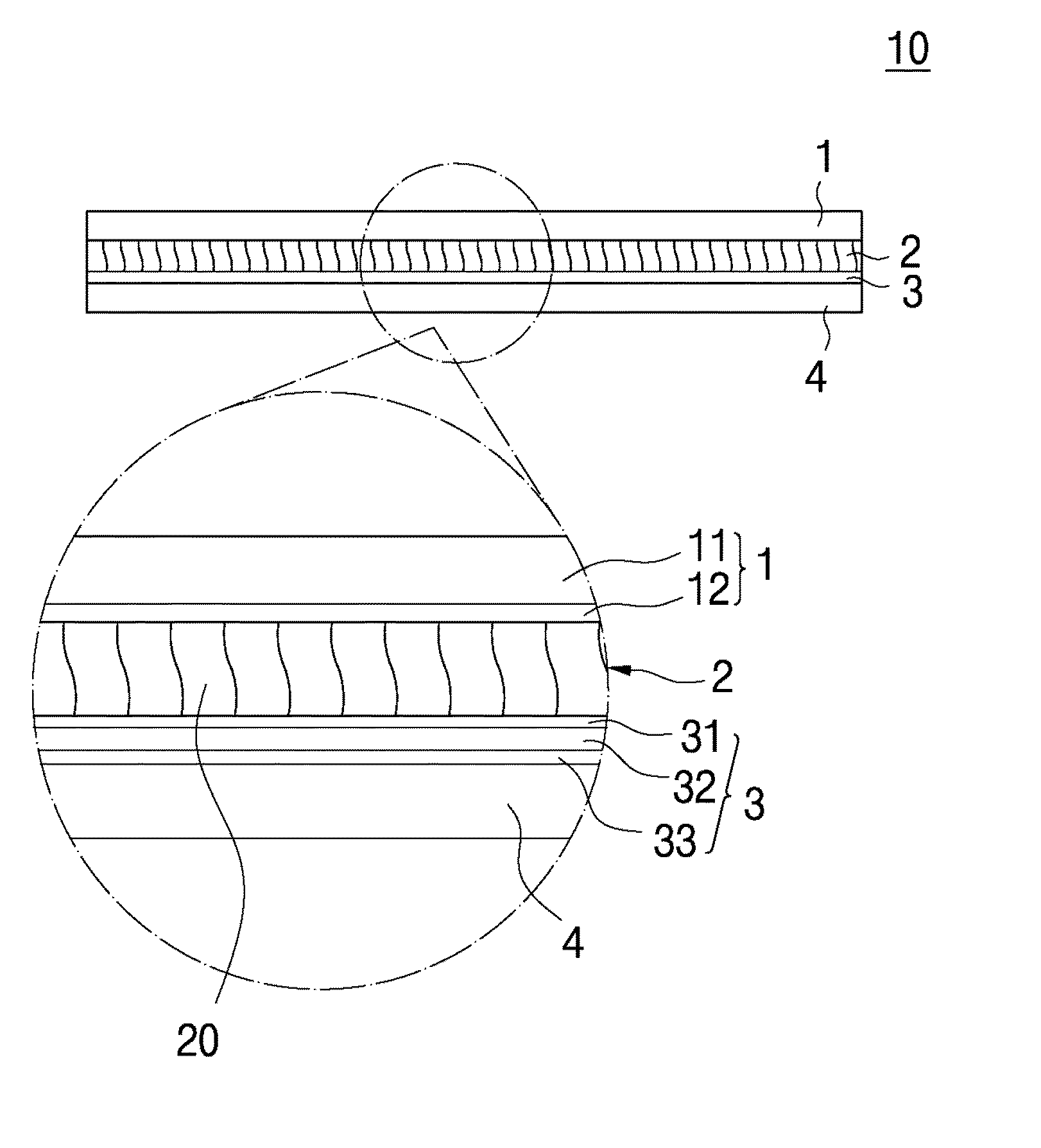

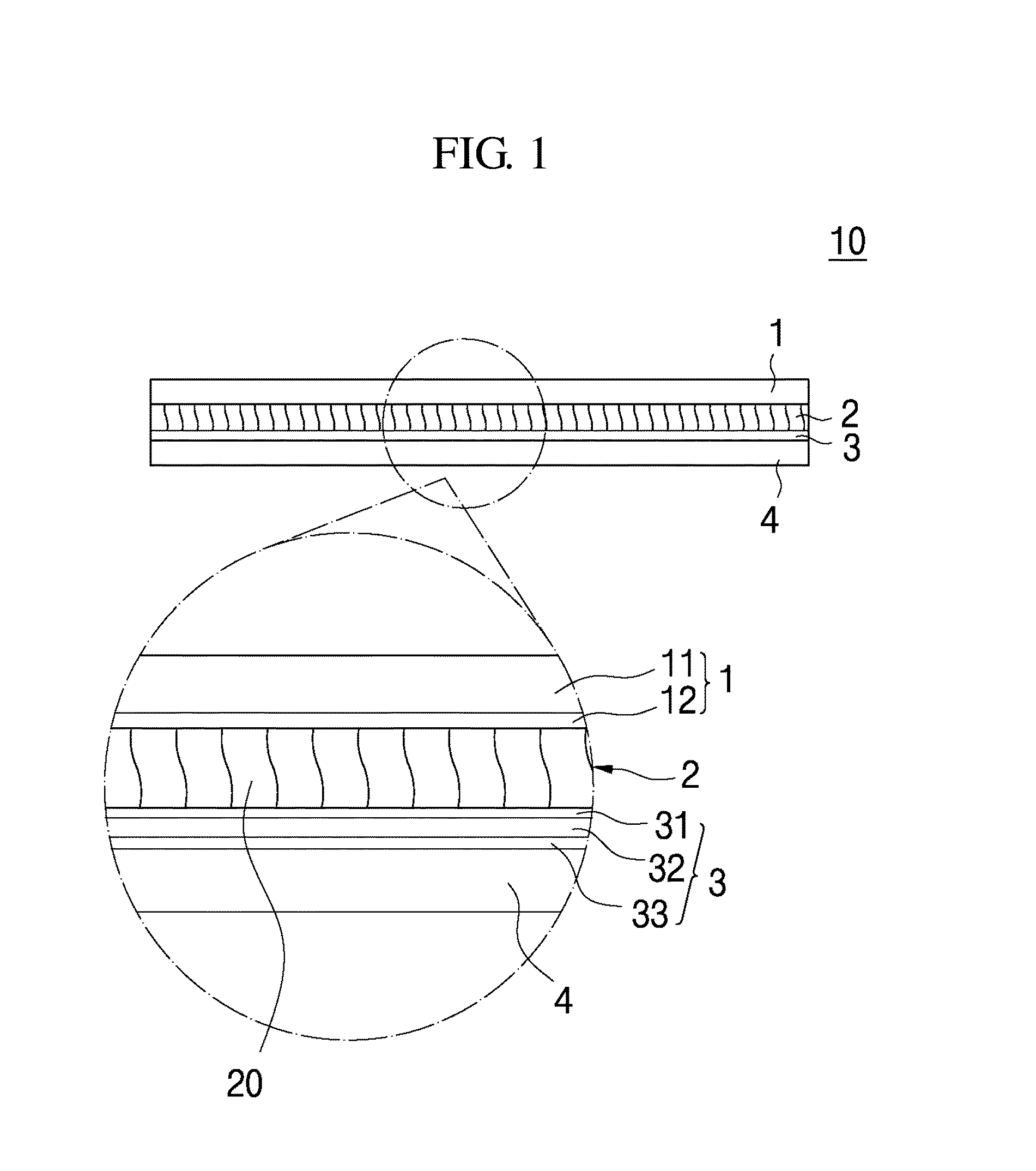

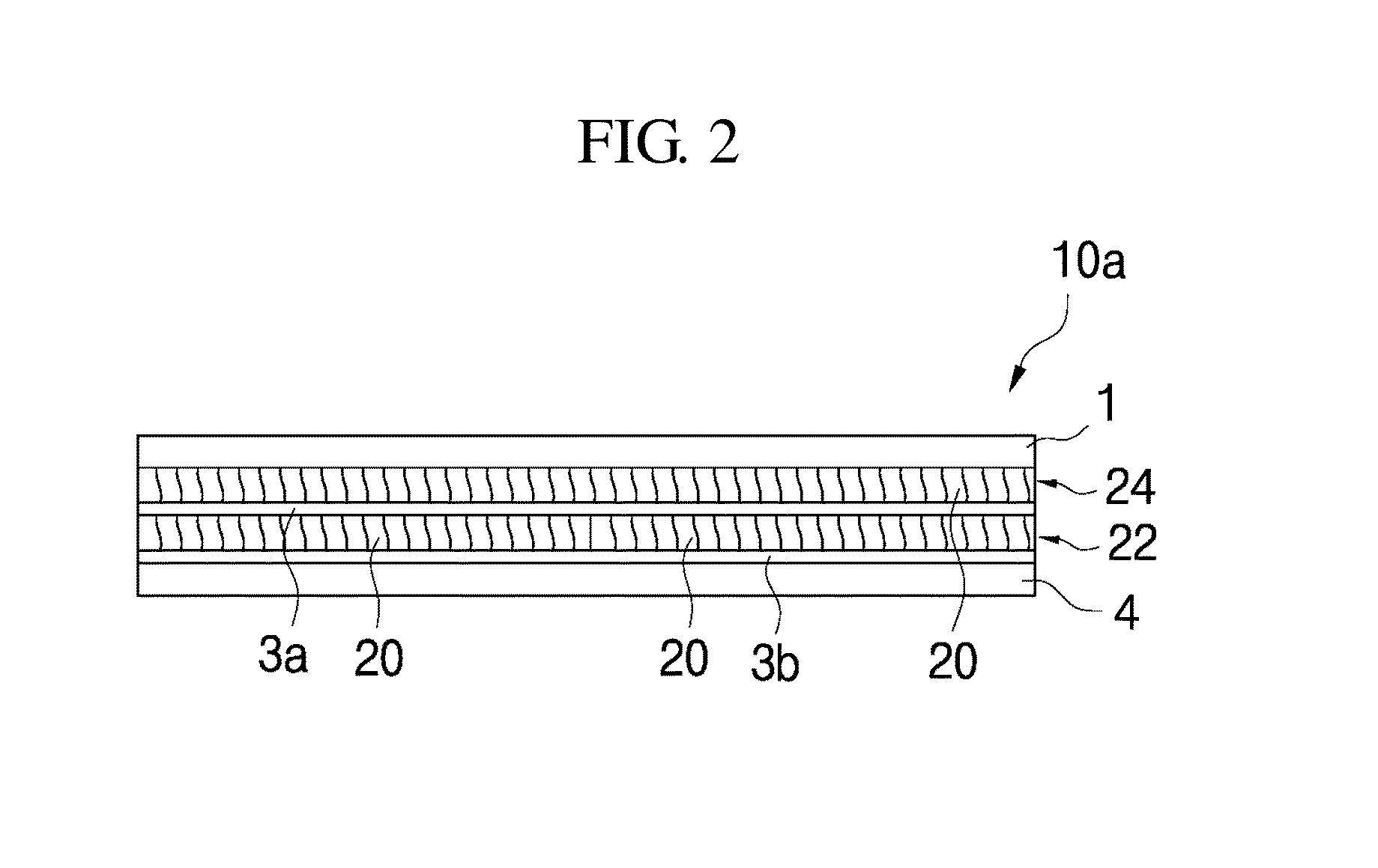

Image

Examples

examples 8 to 11

[0126]Final samples (ARS2-454, ARS2-456, ARS2-457, and ARS2-459) of 40 μm thick of Examples 8 to 11 were prepared by comprising: making an amorphous ribbon made of a Fe67B14Si1Co18 alloy in a thickness of 25 μm by a rapid solidification method (RSP) due to melt spinning; cutting the amorphous ribbon in a sheet form and heat treating the cut sheet at 454° C., 456° C., 457° C., and 459° C., respectively, under no magnetic field, in a nitrogen (N2) atmosphere, for 1 hour, to thereby prepare a laminate sheet of 45 μm thick in the same manner as the Example 1; and performing flake-processing and laminate-processing respectively.

[0127]Permeability values according to the frequency changes were obtained with the samples of Examples 8 to 10, which were illustrated in graphs of FIGS. 13A to 13C.

[0128]In addition, power loss values were measured by using a micro-strip line method shown in FIG. 16, with the samples of Examples 8 to 11, which were illustrated in a graph of FIG. 14.

[0129]The sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com