Silicone-containing acrylic polymers for transdermal drug delivery compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0093]Silicone-containing acrylic copolymers are synthesized by copolymerization using methodologies known in the art. For example, acrylic monomers are copolymerized with silicone-containing acrylic monomers in an appropriate solvent, such as ethyl acetate, with an appropriate initiator, such as 2,2′-azobisisobutyronitrile (AIBN), at an appropriate temperature.

[0094]Silicone-containing acrylic copolymer A is prepared as follows: An initial charge containing 9.7 g methyl acrylate (MA), 20.9 g 2-ethylhexyl acrylate (2-EHA), 95.1 g 3-(tris(trimethylsilyloxy)silyl)propyl methacrylate (TRIS), 0.074 g AIBN, and 125.5 g ethyl acetate (solvent) is mixed in a 2-L round bottom flask, which is installed with a thermometer, condenser, stainless steel stirrer, water bath and dropping funnel. Under stirring, the initial charge is heated to 80° C. and allowed to reflux for 15 minutes. Then a mixture of 29.0 g MA, 62.5 g 2-EHA, 285.3 g TRIS, 0.22 g AIBN and 377.0 g ethyl acetate is uniformly added...

example 2

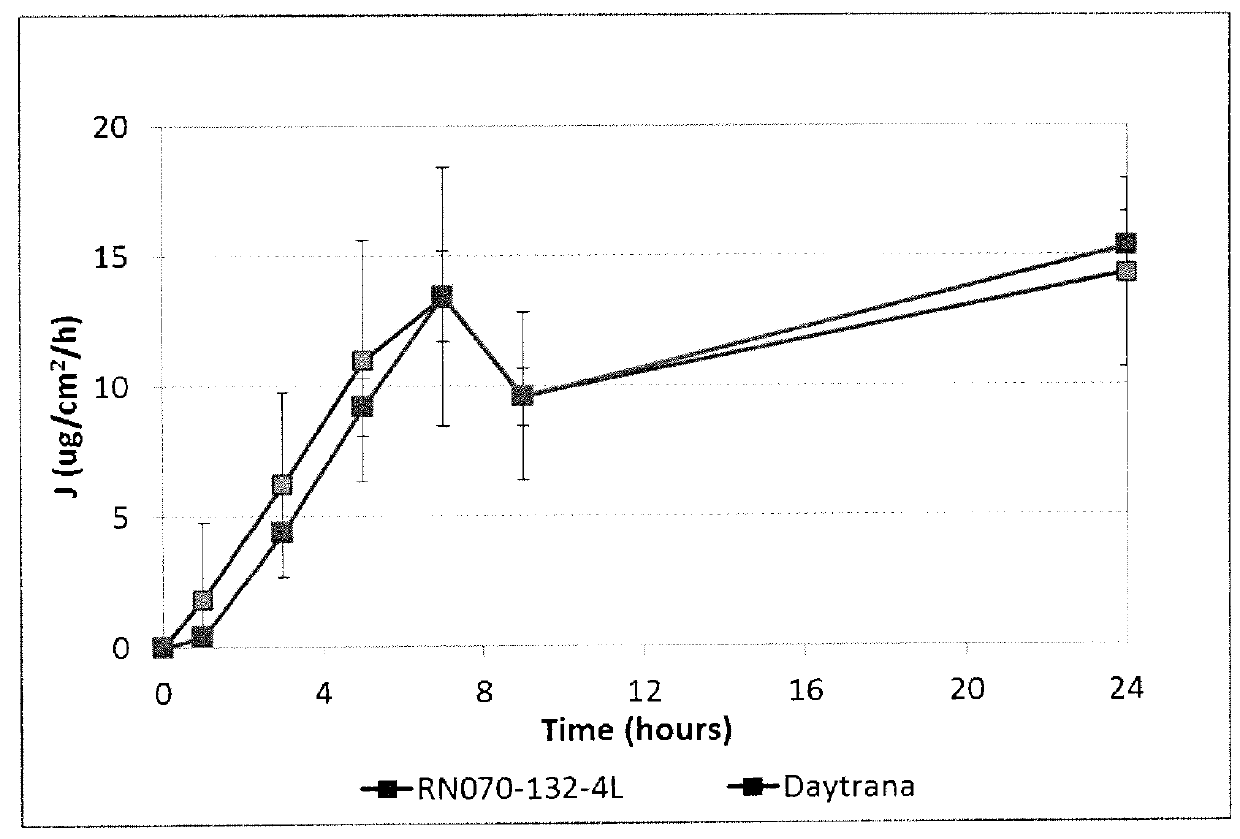

[0097]Methylphenidate was formulated in silicone-containing acrylic polymer B (described above) to prepare a composition comprising 20% methylphenidate and 80% polymer B. Drug flux through human cadaver skin over 24 hours was assessed in vitro. Results as compared to results achieved with the polymer matrix of the commercial Daytrana® product (20% methylphenidate, 80% blend of acrylic pressure-sensitive adhesive polymer and silicone pressure-sensitive adhesive polymer) are shown in FIG. 1 and summarized below.

94 hr FluxFlux Lot #Formulation (SP 9732 Backing)(mcg / cm2 / h)Ratio65654Daytrana9.101.0RN070-132-4L20% MPH + 80% Copolymer B10.481.15

[0098]The results show that the composition based on polymer B achieved a drug flux comparable to that of Daytrana®.

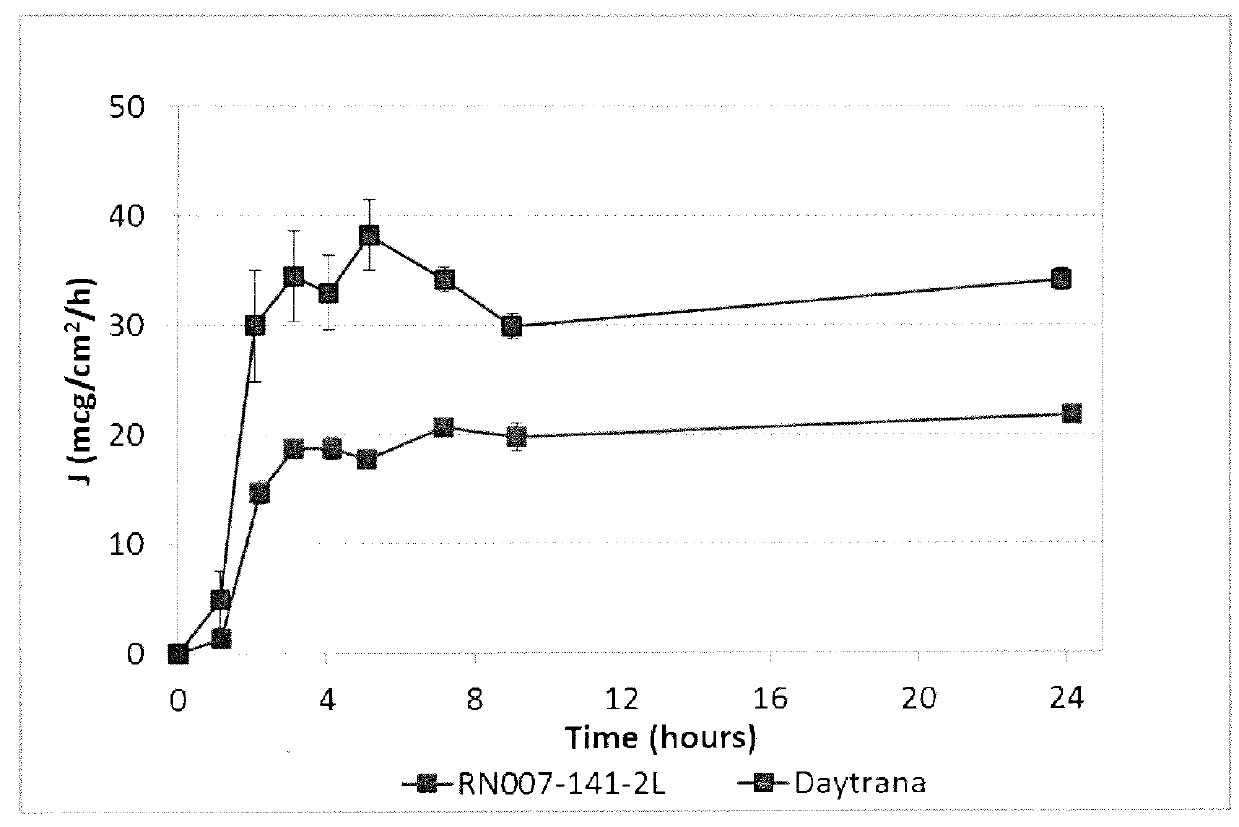

[0099]For comparison, the in vitro flux from a composition prepared with 20% methylphenidate in 80% acrylic pressure-sensitive adhesive (Gelva® 3087) and from Daytrana® are plotted in FIG. 2 and summarized below.

94 hr FluxLot #Formulat...

example 3

[0101]The methylphenidate / polymer B composition described above was applied to a backing and a release liner, and peel force from the release liner was assessed over 4 months. Results as compared to results achieved with the commercial Daytrana® product are shown below.

Peel from Release Liner (g / 0.5″, n = 3)Lot #Formulation (w / w)1M2M3M4MRN056-Freshly made 9.222.439.980.632-4LDaytranaRN070-20% MPH + 80% 23.325.022.418.7132-4LCopolymer B

[0102]The results show that the peel force for the polymer B composition remained stable and low while that of the Daytrana® product increased over time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com