Microwave-Assisted Bitumen Extraction With Vacuum-Assisted Sediment Filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

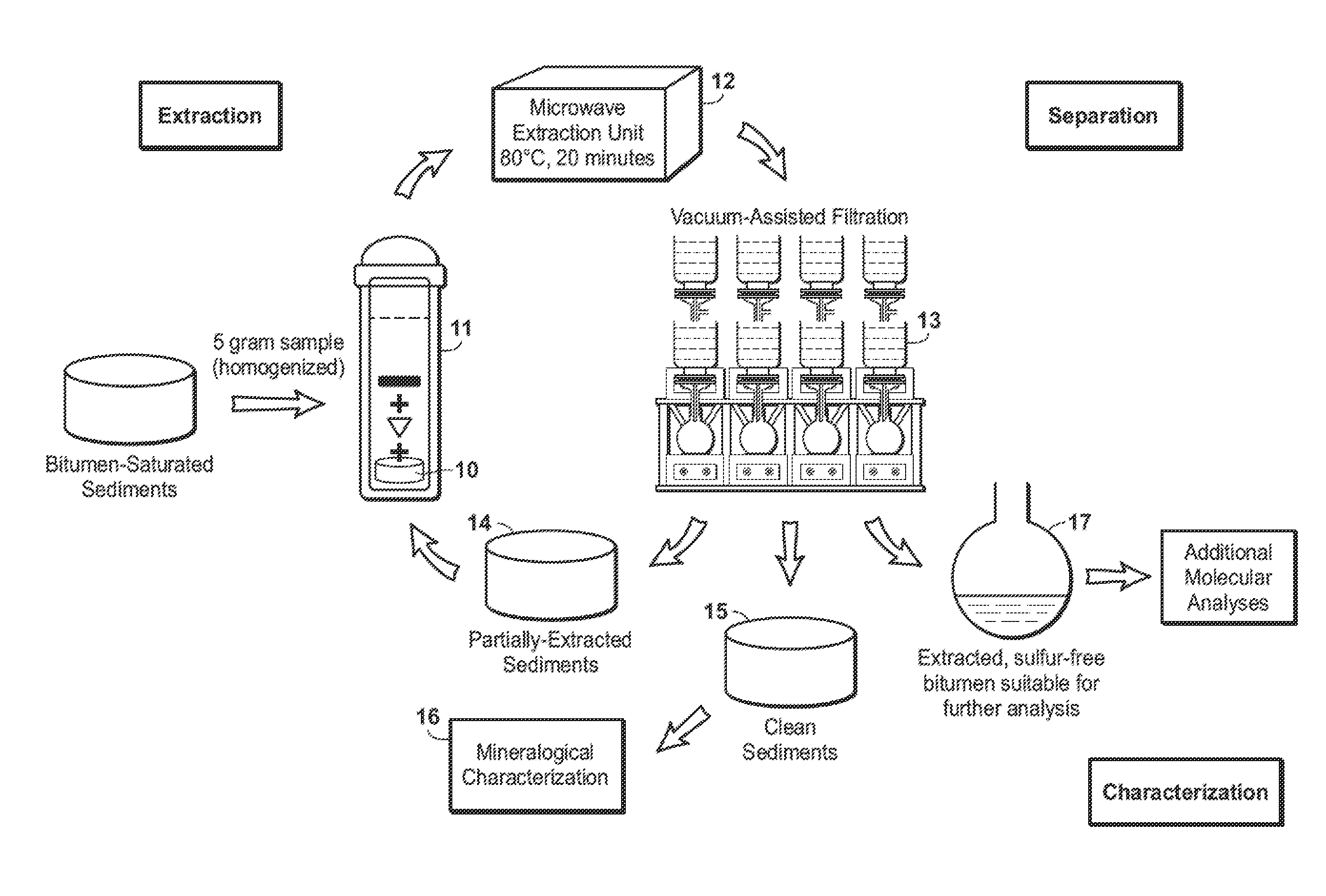

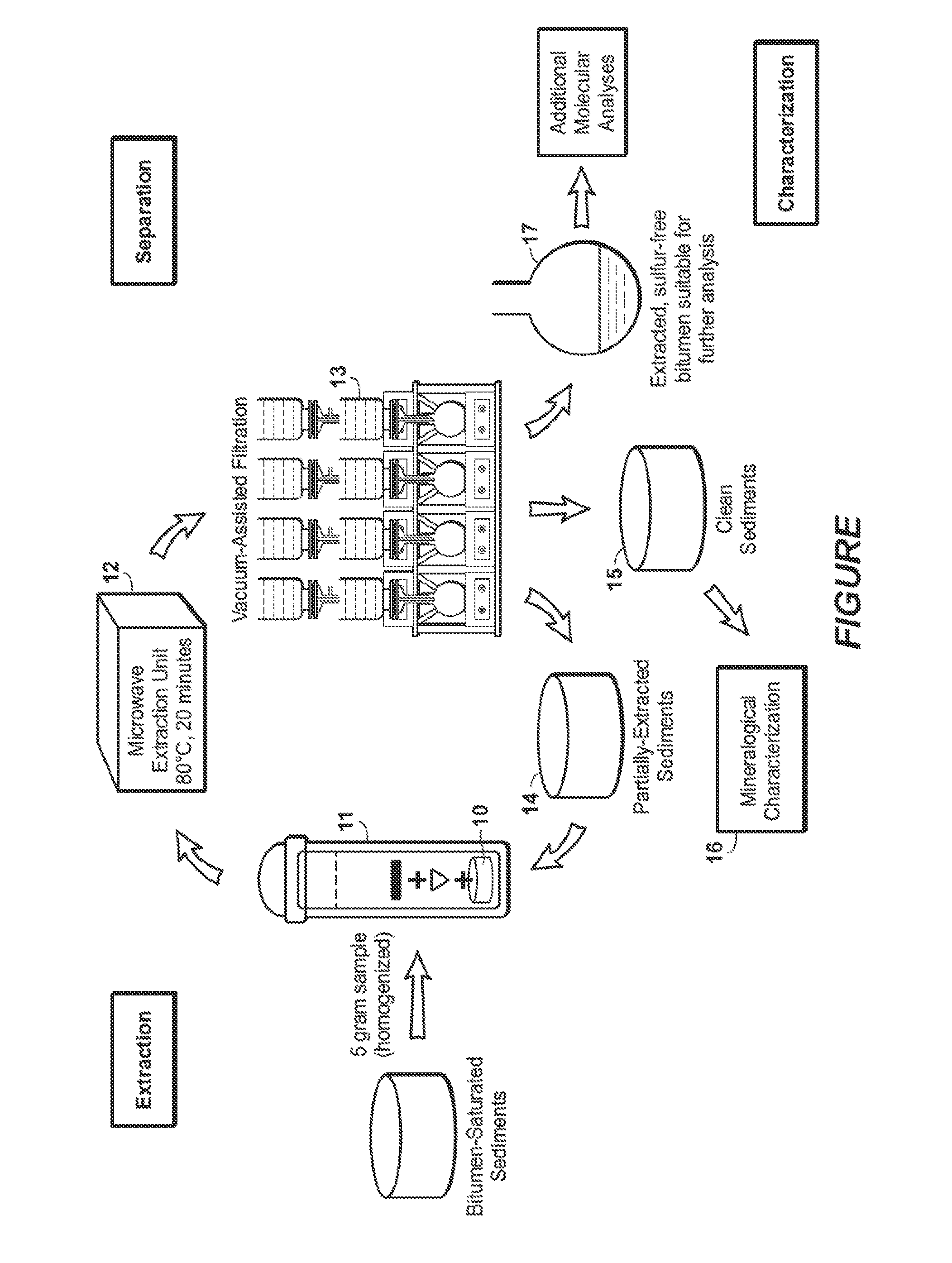

[0012]In order to provide reliable and relevant sample preparation to address questions related to daily mining operations, any analytical extraction technique for oil sands samples should address a number of criteria: (a) it needs to have a high extraction efficiency in order to allow the extraction of large volumes of bitumen and provide adequate sediment mass for routine mineralogical analyses; (b) the extraction technique should use the minimal volume of organic solvent necessary in order to minimize potential environmental impacts; (c) it needs to be relatively simple and fast for rapid turn-around, on the order of a few hours, to provide samples for “just-in-time” analyses at the mine site; and (d) the technique must not alter either the mineralogical or geochemical composition of the sample so that prepared samples are reflective of the composition of the native sample. For purposes of the present document, including the claims, the term “oil sand(s)” will be understood to in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com