Bioinert article and its use

a bioinert and article technology, applied in the field of articles, can solve the problems of improper device function in vivo and in vitro, cell adhesion, irritation of surrounding tissue, etc., and achieve the effect of enhancing the ingrowth of a permanent implant into the surrounding tissue and increasing specific interactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

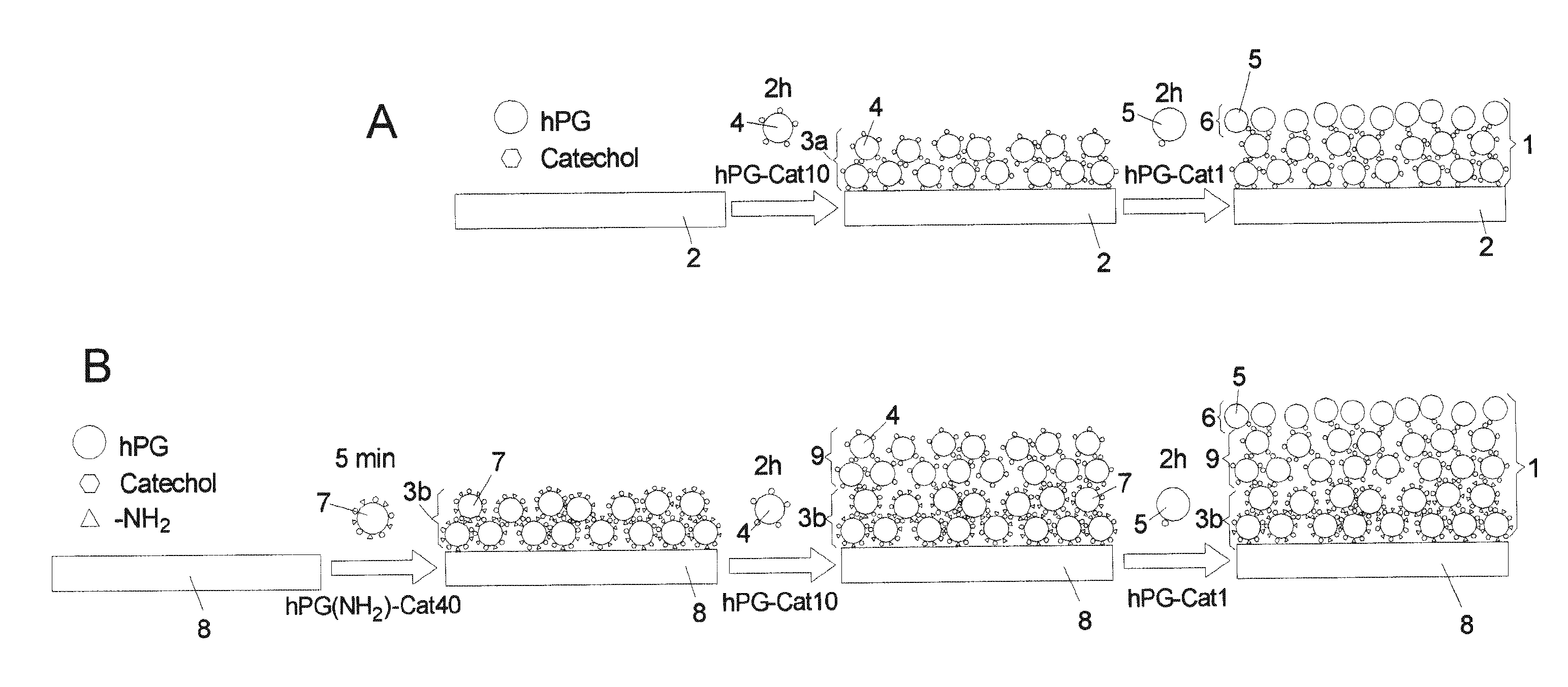

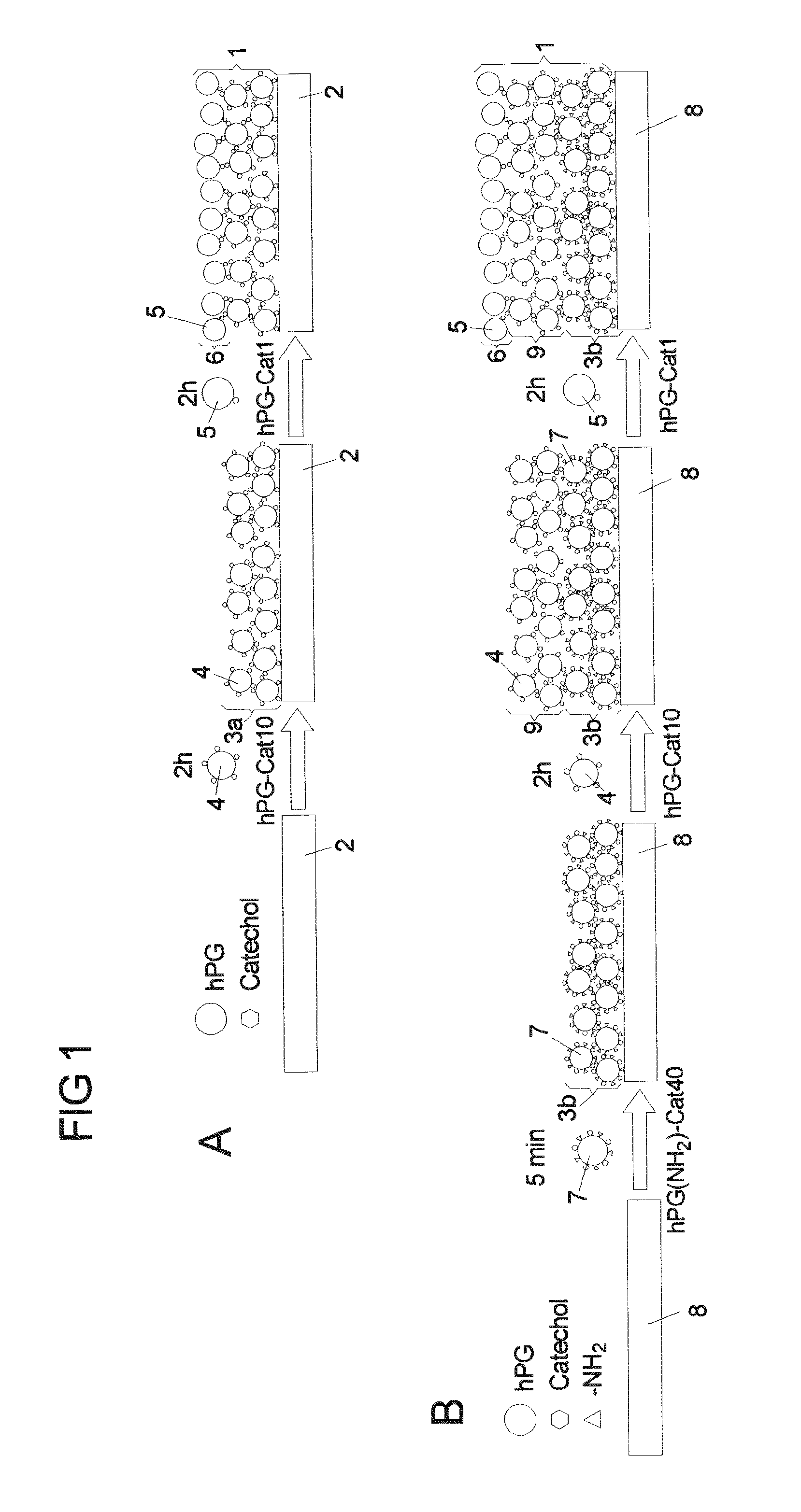

[0107]FIG. 1A is a schematic depiction of the steps to be performed in order to produce an article coated with an antifouling-coating of a two-layered polymer film 1 on a metal substrate 2. For building up the polymer film 1, a multiple catechol-functionalized hyperbranched polyglycerol (hPG) 4 with a degree of functionalization of 10% (hPG-Cat10) is produced in a first step from hPG and a functionalization compound bearing a catecholic group. This hPG-Cat10 4 was developed to form an inert foundation layer 3a which can effectively shield metals, metal oxides and other substrates. The foundation layer 3a can also be referred to as lowest polymer layer of the layered polymer film 1. The foundation layer 3a is a multi-molecular layer in which the individual catechol-functionalized polyglycerols 4 (which serve as second or further polymer) are cross-linked to each other via their catechol groups. In addition, the catechol groups of the polymer 4 of the foundation layer 3a serves for an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com