Apparatus for degassing a nuclear reactor coolant system

a technology for coolant systems and nuclear reactors, applied in nuclear elements, separation processes, greenhouse gas reduction, etc., can solve the problems of significant energy and significant building space and support systems, and achieve the effect of minimizing the required number of contactors and improving the efficiency of membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

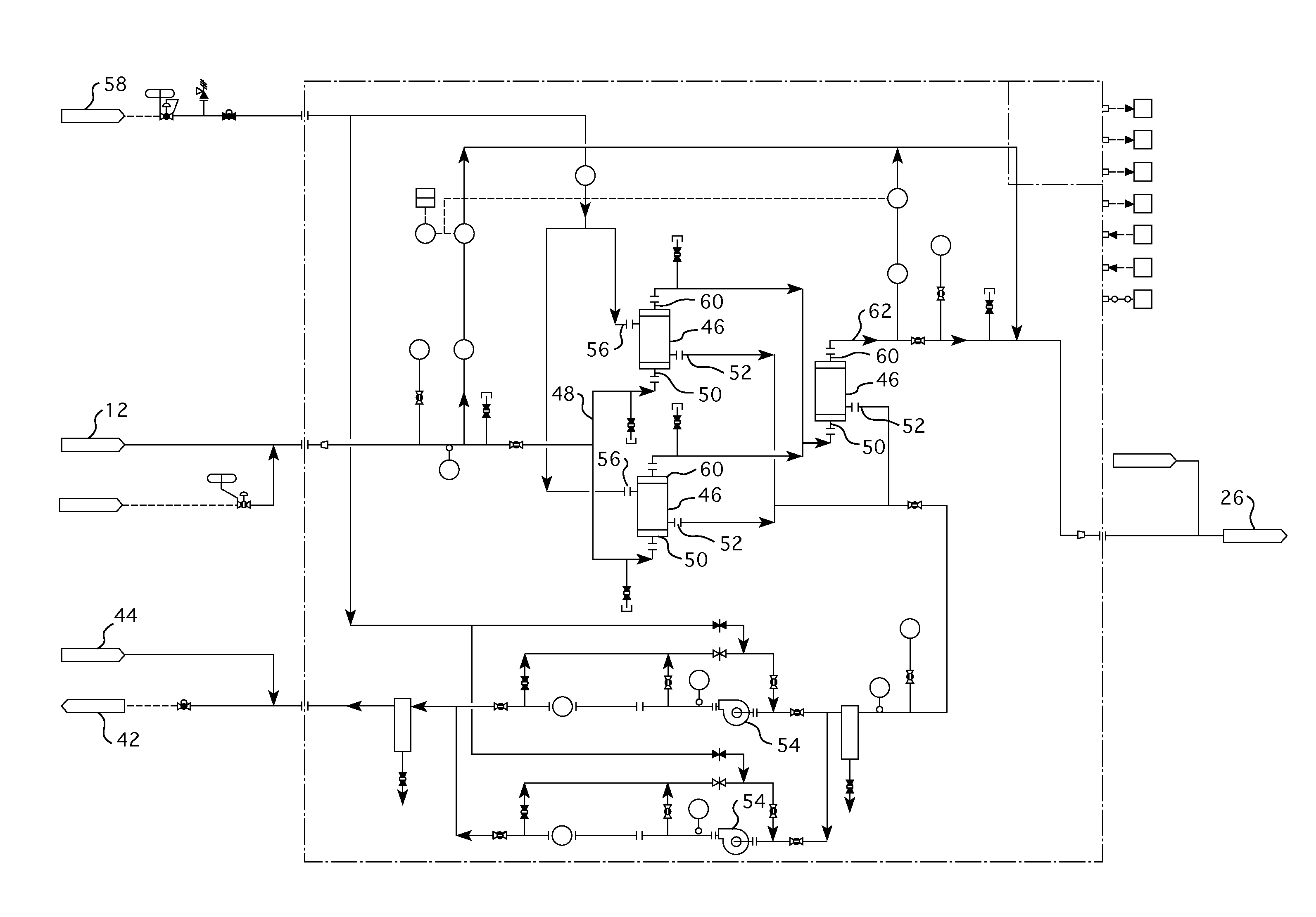

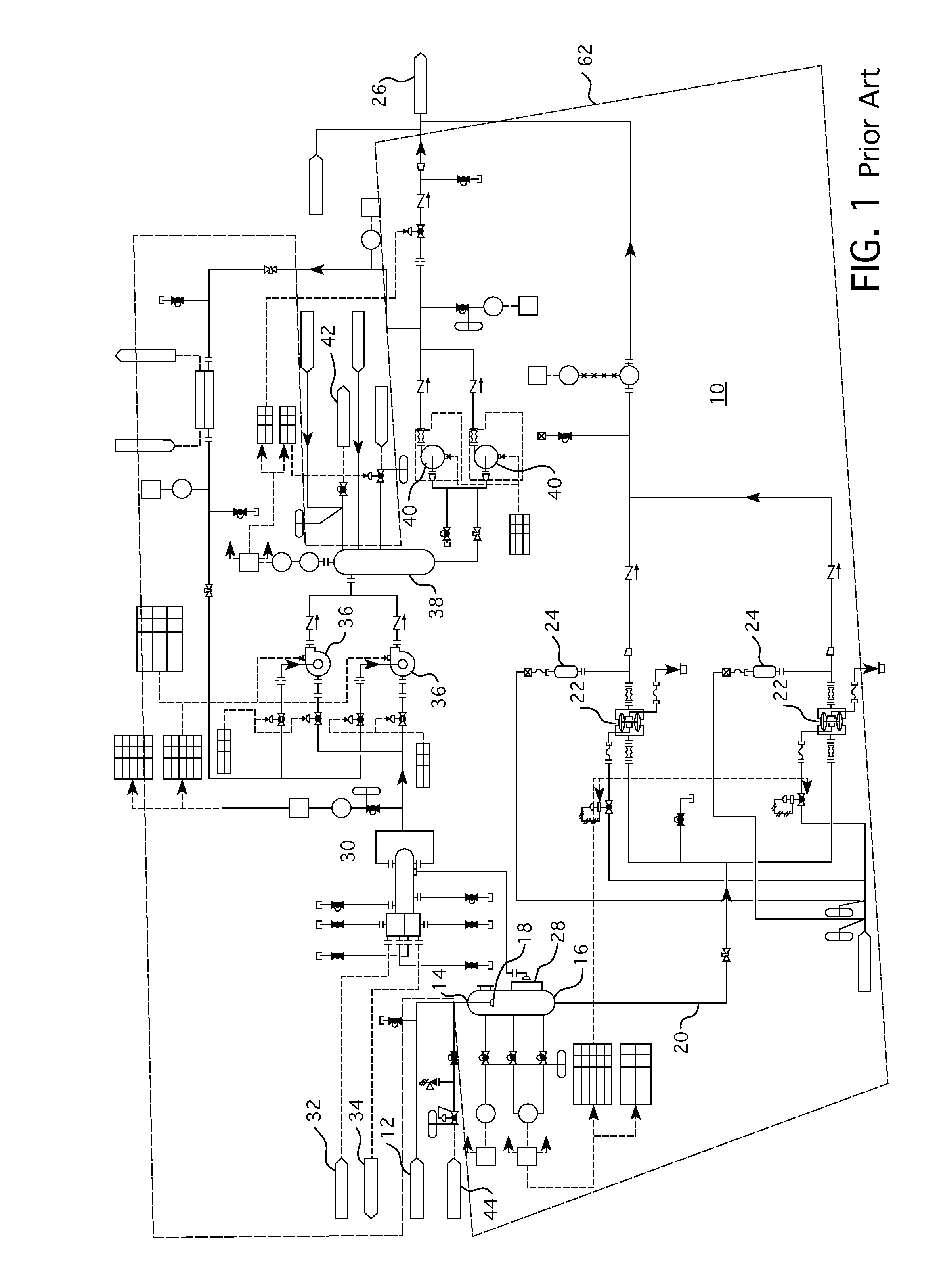

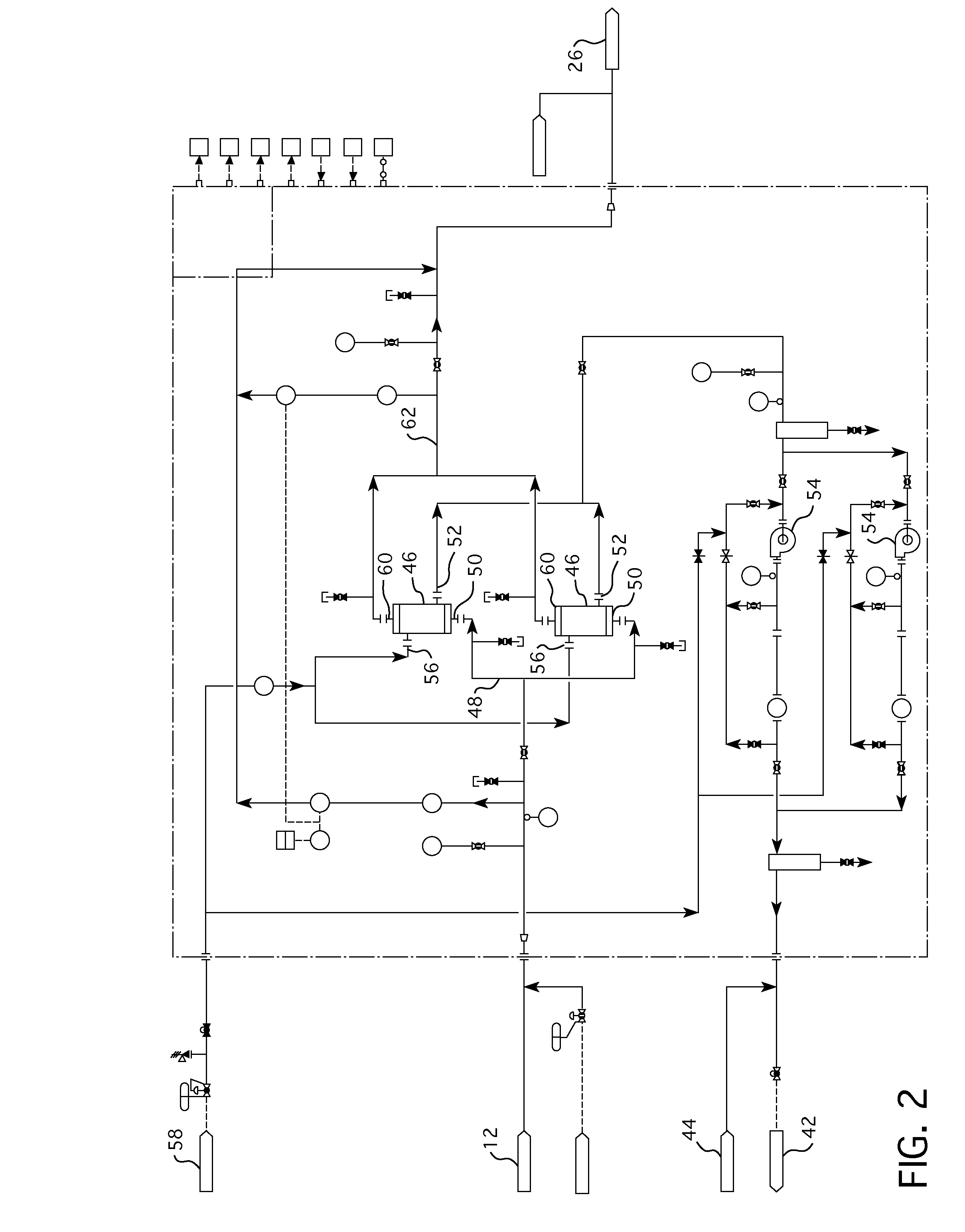

[0017]This invention utilizes a known and established technology of gas membranes to remove dissolved gases from the reactor coolant. While this is a known and proven technology for some applications, it has not been previously employed to handle mildly acidic and radioactive solutions as exists in interfacing with the primary coolant of a nuclear reactor system, as evidenced by the alternative reactor degasing systems proposed in the past and described in the evaluation of prior art set forth in the Background of U.S. Pat. No. 4,647,425.

[0018]In accordance with this invention, one or more alternate “contactors” which respectively house a gas membrane are aligned in series and / or parallel, as required to handle the desired flow and the degree of gas removal. Liquid containing primarily dissolved hydrogen and the radioactive gases, i.e., xenon and krypton, enters the contactors at a relatively low pressure and exits the membranes degassed to the desired level. A vacuum is applied to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com