Lithium-ion battery and method for preventing the dissolution of metals from a cathode of said lithium-ion battery and/or damage to an sei layer of an anode of said lithium-ion battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

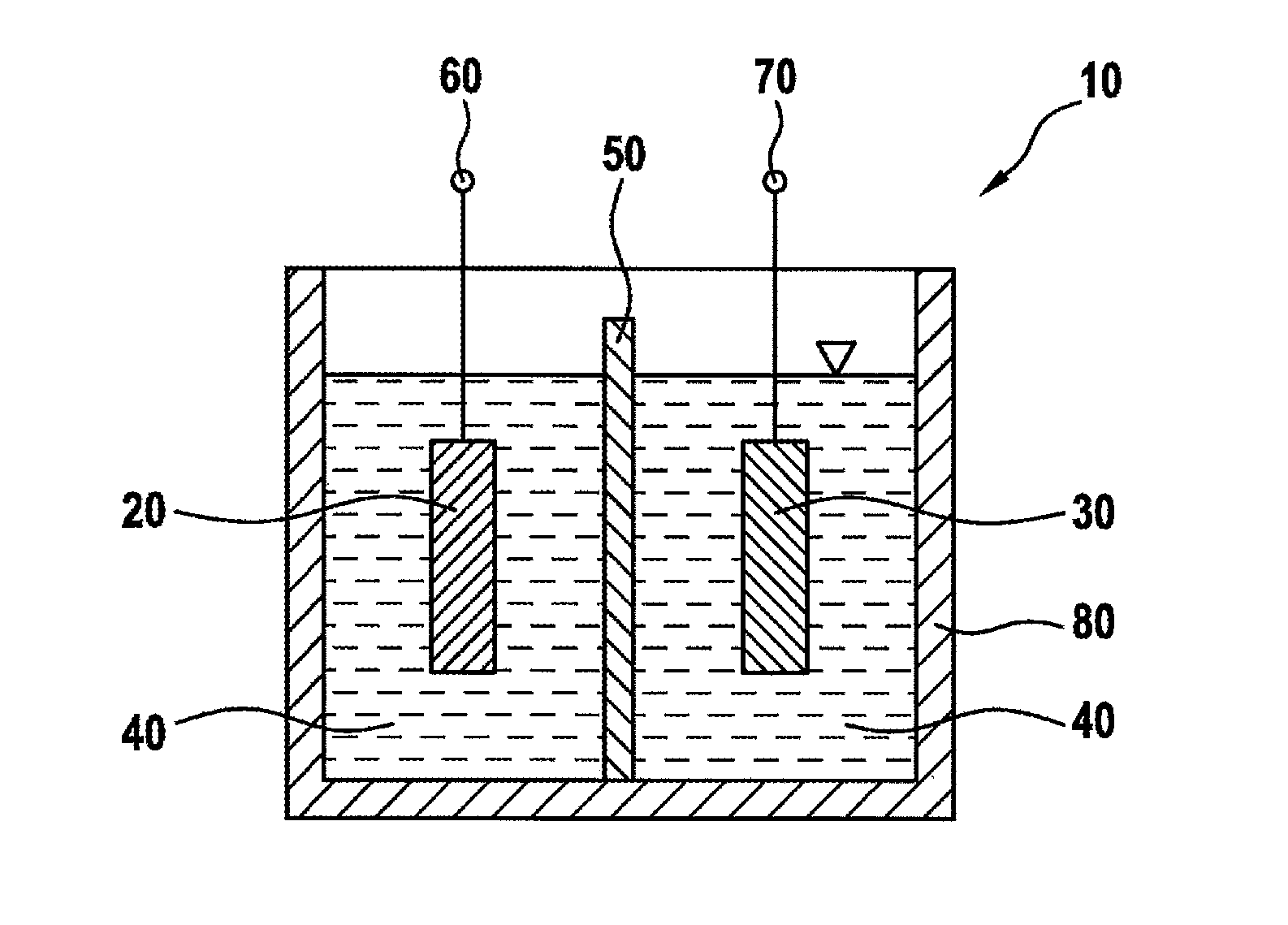

[0024]FIG. 1 depicts a general configuration of a lithium-ion battery 10 according to an example embodiment of the present invention. An anode 20 encompassing active anode material, and oppositely a cathode 30 encompassing active cathode material, are disposed in a housing 80. Disposed therebetween is a liquid electrolyte 40 that is in contact with anode 20 and cathode 30, and a separator 50 that prevents the occurrence of internal short circuits between electrodes 20 and 30 by spacing the two electrodes 20, 30 apart from one another and electrically insulating them from each other. Liquid electrolytes 40 typically encompass a solvent and a lithium-containing salt. Anode 20 is connected to an anode terminal 60, and cathode 30 to a cathode terminal 70.

[0025]The decrease in battery capacity over time depends on the active cathode material that is used. Whereas an appreciable decrease in capacity over time is to be observed with lithium manganese oxide as an active cathode material, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com