CO3W3C Fishbone-Like Hard Phase-Reinforced Fe-Based Wear-Resistant Coating and Preparation Thereof

a technology of hard phase reinforcement and wear-resistant coating, which is applied in the field of material surface wear-resistant coating and preparation thereof, can solve the problems of particularly severe wear failure of mechanical parts, and achieve the effect of simple and convenient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0026]The surface of the matrix is polished to remove oxide layer, the treated matrix is placed on a plasma cladding working table, and its position is adjusted.

[0027]The WC powder with granularity of 280-320 meshes and the Fe-based alloy powder of 100-200 meshes are screened to prepare the Fe-based WC mixed alloy powder including the following components in weight percentage: C: 3.24%, Cr: 7.2%, Ni: 4.4%, W: 49.56%, Co: 7.2%, Si: 0.04%, and the remaining is Fe. The powder is subjected to pre-treatment, put in a stirrer to stir for 50-60 min, put in a drying oven to heat at 150° C., and put in a powder feeder. The cladding process includes: A working current of 140 A, a working voltage of 11 V, powder feeding gas and protecting gas are argon gas, a powder feeding gas pressure of 300 MPa, a protecting gas pressure of 800 MPa, distance from a nozzle to the surface of the matrix is 10 mm, and a scanning speed of 80 mm / min. The plasma cladding machine is turned off after finishing the c...

example 2

[0030]The pre-treatment process of the matrix is kept the same as that of Example 1, and the prepared Fe-based WC mixed alloy powder includes the following components in weight percentage: C: 3.77%, Cr: 5.4%, Ni: 3.3%, W: 57.83%, Co: 8.4%, Si: 0.03%, and the remaining is Fe. The process parameters of the plasma cladding are the same as those of Example 1, and a cladding layer with a superior performance can be obtained.

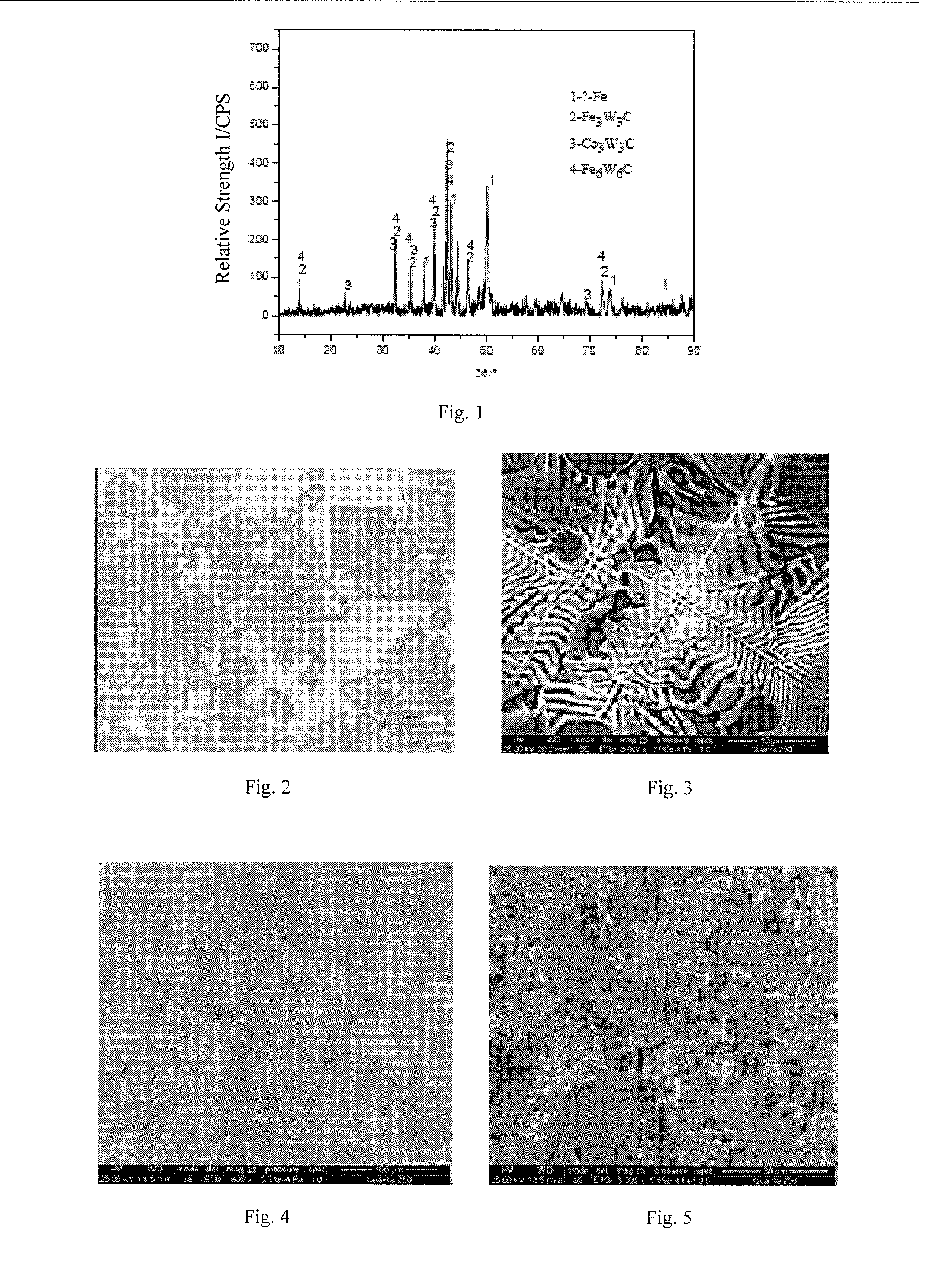

[0031]Mutual-rubbing test is performed on the M-200 wear testing machine for the prepared Co3W3C fish-bone-shape hard-phase reinforced Fe-based wear-resistant coating with a wear time of 40 min, a wear amount of 0.0032 g and a very superior wear resistance. FIG. 1 is an XRD graph of the plasma cladding layer of Example 2, the Co3W3C in the cladding layer plays a big role in improving the performance thereof. In FIG. 4, it can be seen that a large amount of fish-bone-shape hard phase Co3W3C on a wear surface is embossed on the surface of the matrix.

example 3

[0032]The pre-treatment process of the matrix is kept the same as that of Example 1, and the prepared Fe-based WC mixed alloy powder includes the following components in weight percentage: C: 1.89%, Cr: 11.7%, Ni: 7.15%, W: 28.81%, Co: 4.2%, Si: 0.065%, and the remaining is Fe. The process parameters of the plasma cladding are the same as those of Example 1, and a cladding layer with a superior performance can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com