Discharge head for a vertical pump and vertical pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

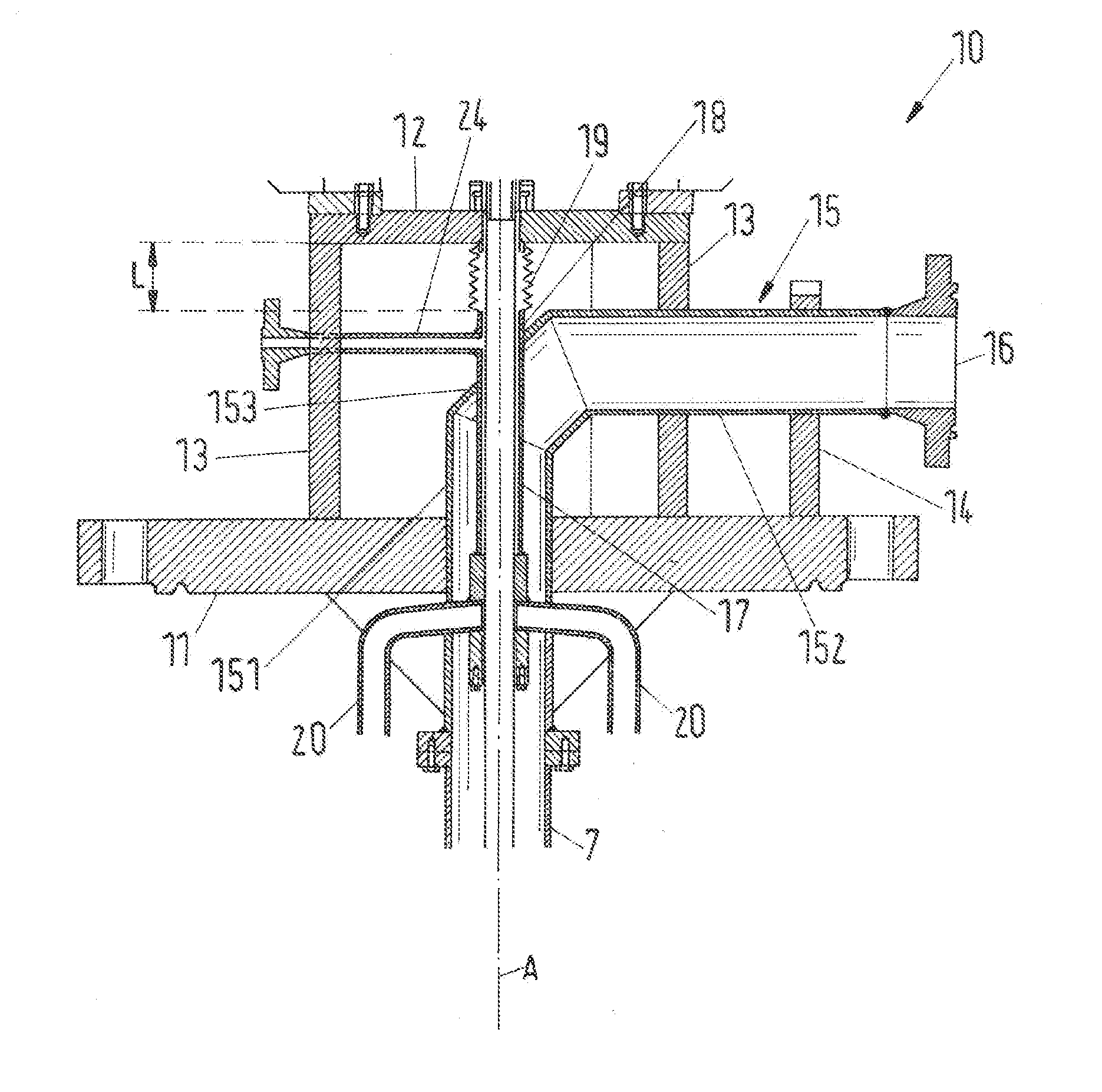

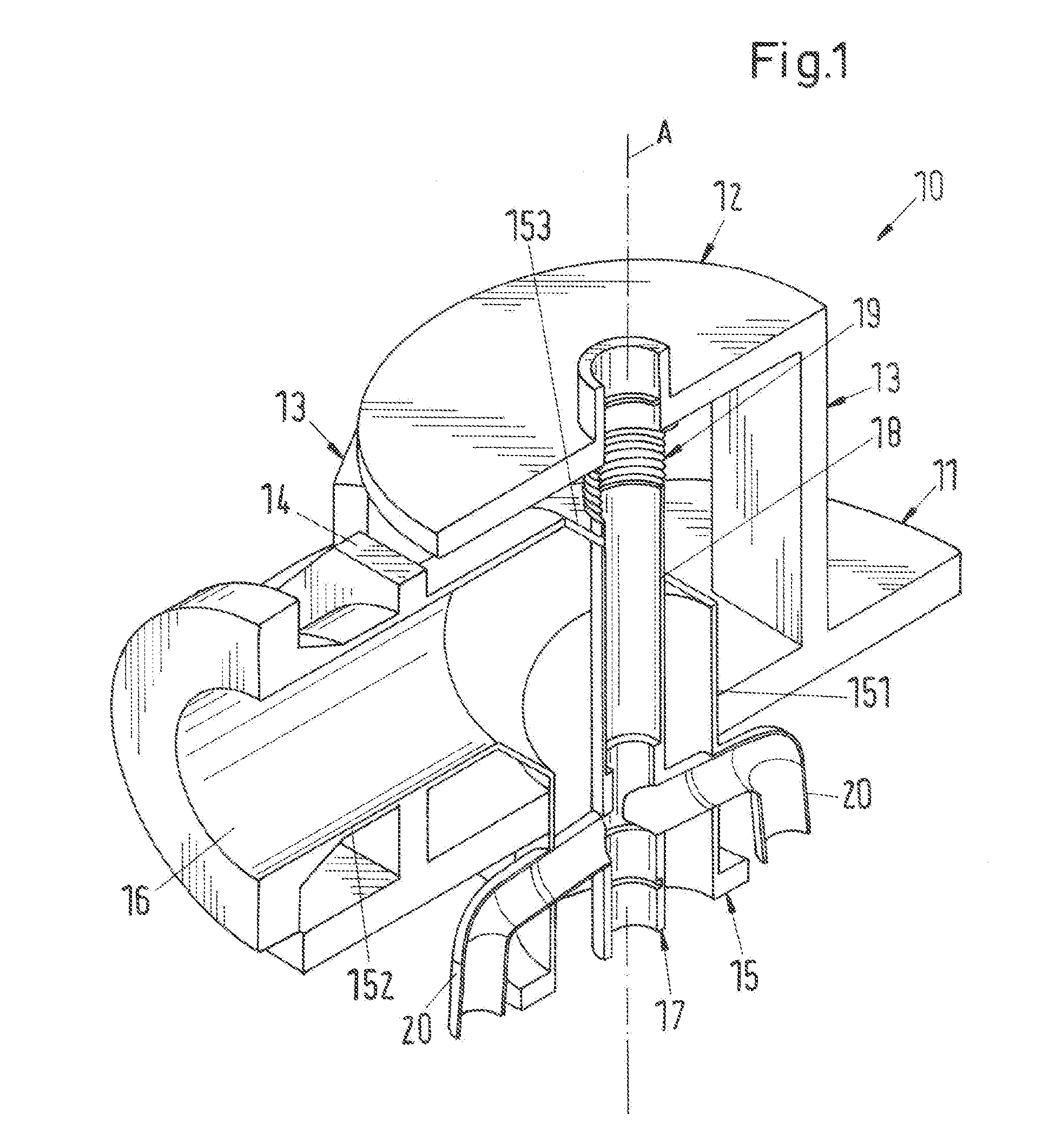

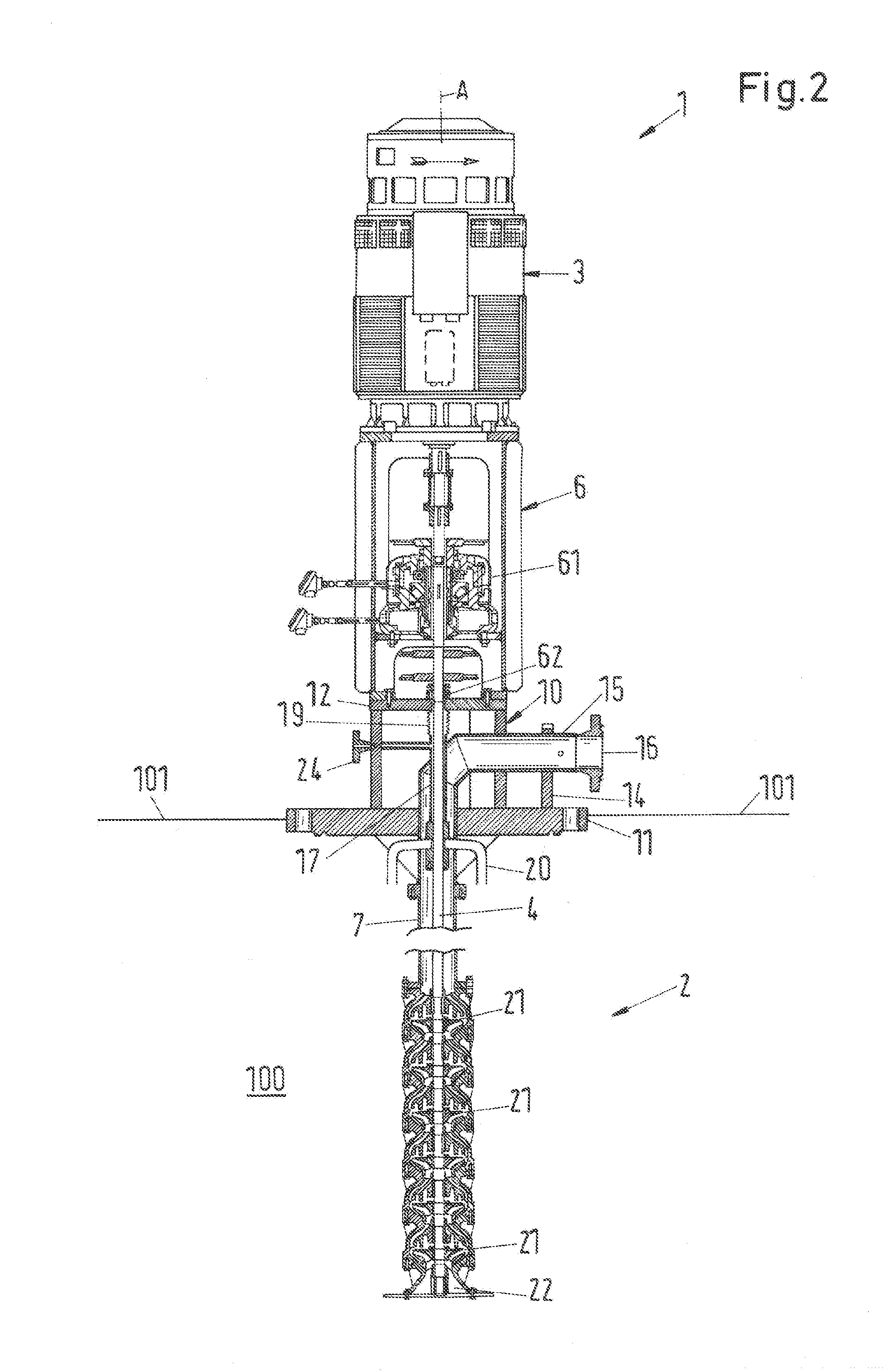

[0035]In the drawings respective identical parts or parts having the same function or an analogously same function are designated with the same reference numerals.

[0036]FIG. 1 shows a perspective, cross-sectional view of an embodiment of a discharge head for a vertical pump according to the invention. The discharge head is designated in its entity with reference numeral 10. FIG. 2 shows a cross-sectional view of an embodiment of a vertical pump according to the invention being designated in its entity with reference numeral 1 and comprising a discharge head 10 according to the invention.

[0037]In the following description reference is made by way of example to the important application that the vertical pump is designed and adapted for a solar energy system which is a concentrated solar power (CSP) system using molten salt as the heat transfer fluid (HTF) or as the heat storage fluid, respectively. More particular, in this example the vertical pump is mounted to a tank for molten sal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com