Process for reducing the amounts of zinc (ZN) and lead (PB) in materials containing iron (FE)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

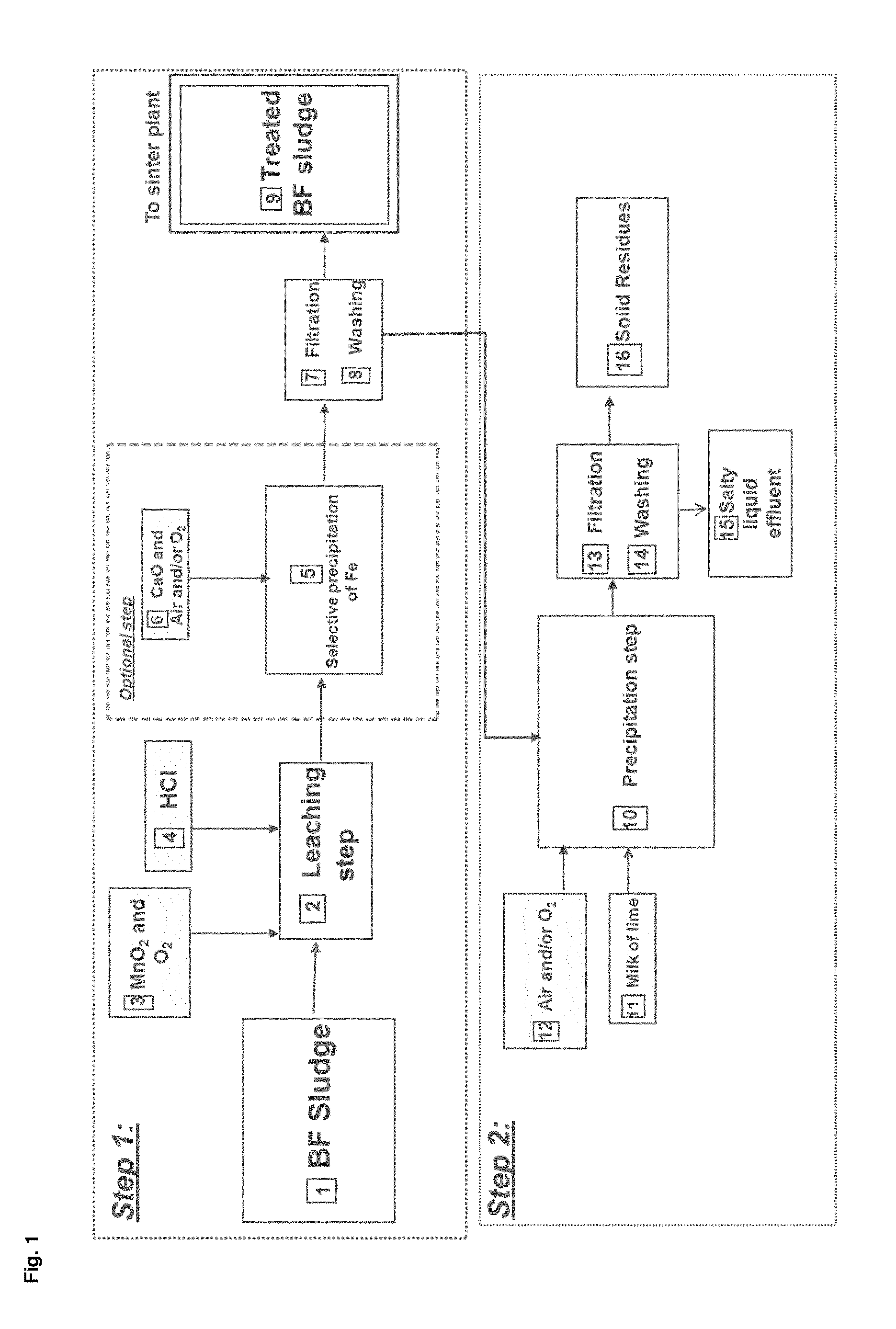

[0120]FIG. 1 describes an embodiment of the process according to the present invention. The starting material to be treated is a blast furnace sludge 1 which corresponds in fact to the sludge rejected at the outlet of the gas cleaning plant.

[0121]The process can be divided in two major steps: step n°1 corresponding to the treatment of the blast furnace sludge and step n°2 corresponding to the recovering of the solubilized metals.

[0122]The treatment of the blast furnace sludge 1 consists in selectively removing the undesirable contaminants from the ferrous matrix namely: Zn and Pb. This is achieved by submitting the blast furnace sludge 1 to a leaching step 2 taking place preferably in a series of agitated reactors working in cascade in order to better control the pH and the addition of the oxidizing agent. The reaction takes place at a temperature of about55 ° C. This leaching step 2 is carried out with the addition of an oxidizing agent which is a mixture of MnO2 and O2 3 and a sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com