Fetal health monitor

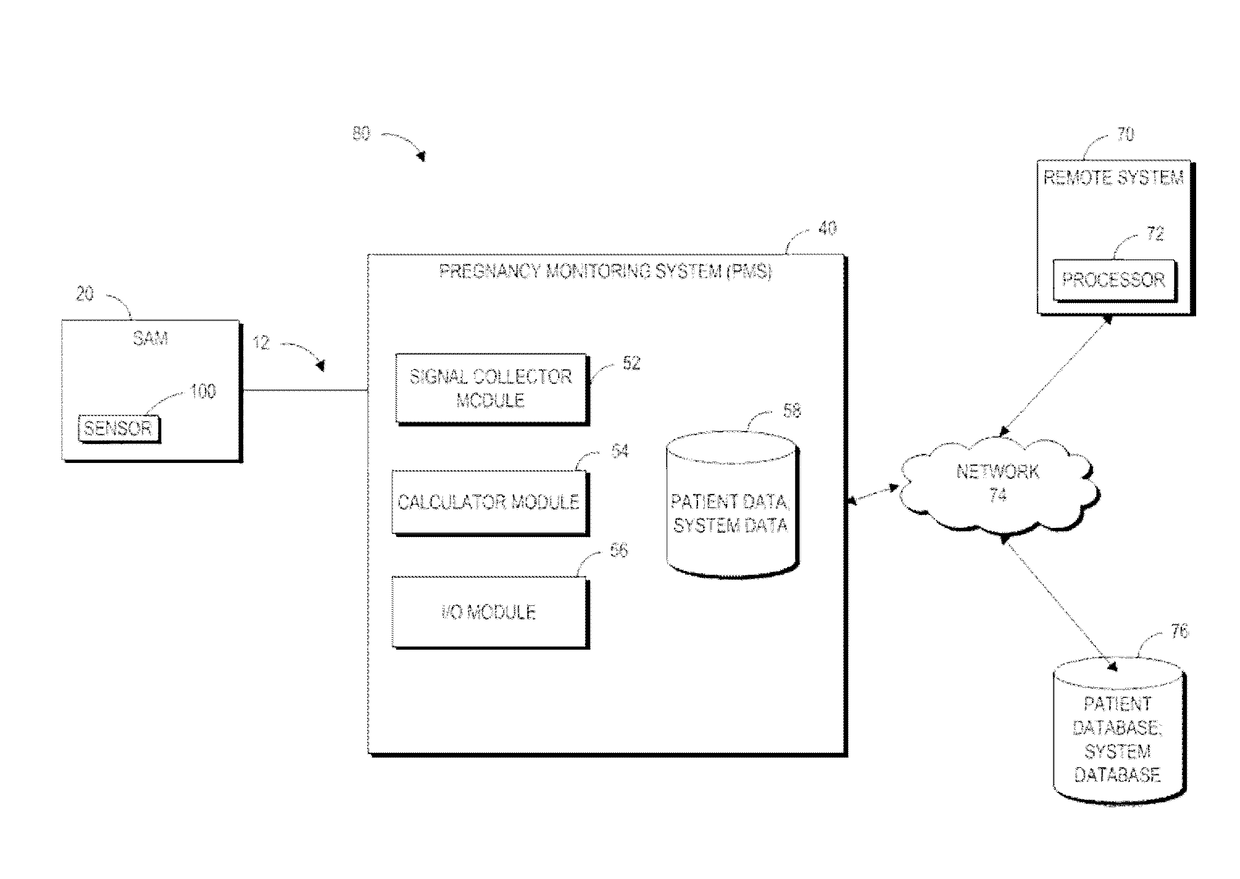

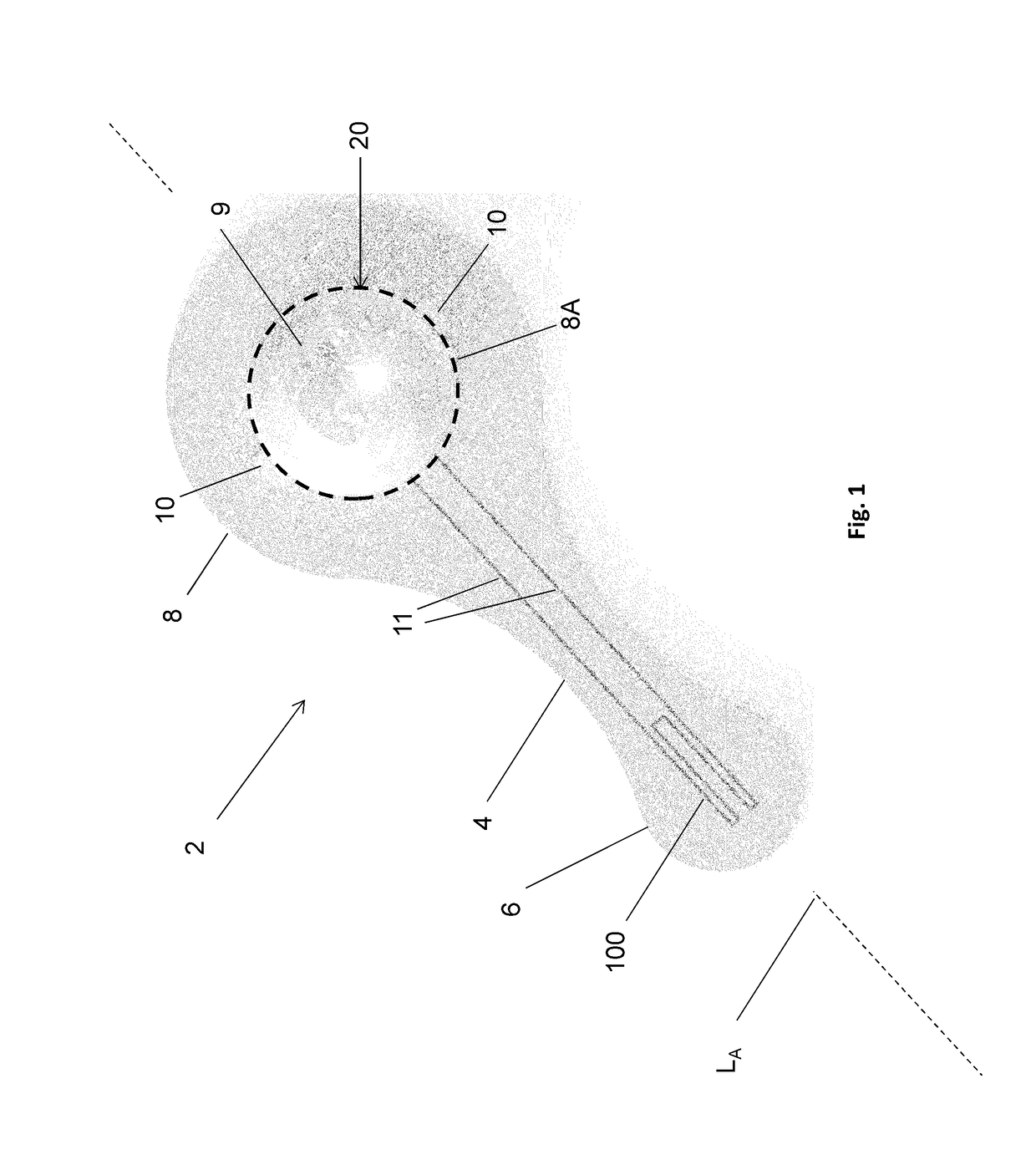

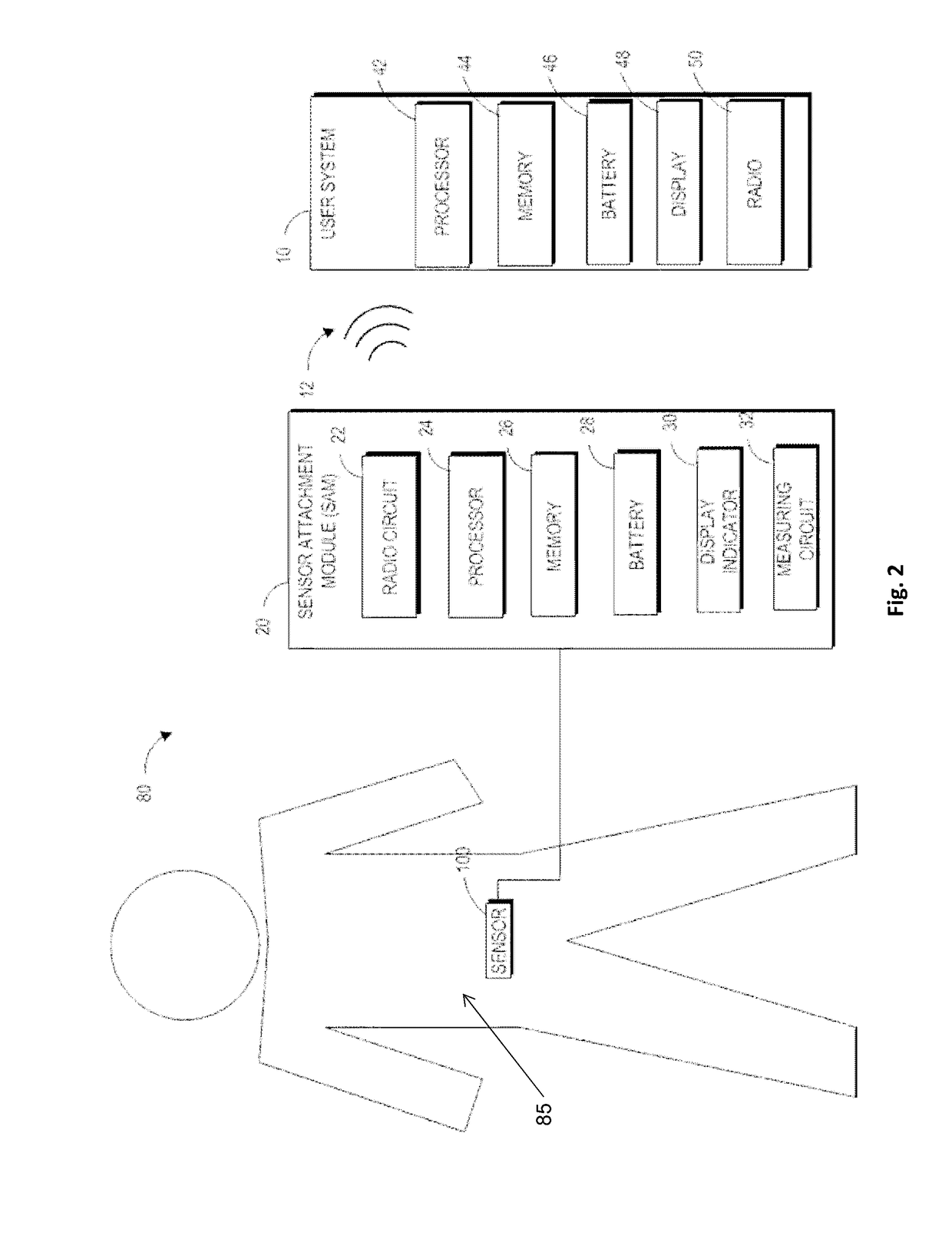

a technology for monitoring devices and fetal bodies, applied in the field of fetal health monitors, can solve the problems of inability to market products for continuously monitoring inability to monitor the health of a baby in-utero, and inability to accurately predict pregnancy outcome,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Processing Guide for Transferring a Structured Metal Thin Film from a Shape-Memory Carrier onto a Silicon Elastomer

[0166]This protocol is meant to serve as a processing guide for transferring wrinkled metal thin films from a substrate (e.g., Grafix Arts polystyrene shrink film) onto an elastomer (e.g., ECOFLEX30™ silicon elastomer). Specific parameters are given for platinum strain gauges and gold interconnects. Adjustments may be made for specific process applications.

[0167]Grafix Frisket Film is mounted to rigid PMMA support. A mask design is laser cut using Grafix Frisket Film using laser settings of 75% power and 100% speed. For convenience, scotch tape is placed across trace width before removing the mask from the support (in order to not distort trace width).

b. Polystyrene (PS) SMP (Grafix Arts)

[0168]Grafix PS sheets are laser cut with laser settings of 78% power, 100% speed and placed concave up (using weights to flatten edges) and then ligned length to length (orient such th...

example 2

Densification and Alignment of CNTs using Polyolefin

[0174]This was accomplished by first dispersing CNTs (0.05% wt / v) in a solution of chloroform. CNTs were sonicated for 30 minutes in an ice bath and centrifuged at 10,000 rpm for one hour. This process is also possible in aqueous solution. For example, CNTs can be dispersed into an aqueous solvent when a surfactant, such as sodium dodecyl sulfate (SDS), is present (Yu, J.; Grossiord, N.; Konin, C. E.; Loos, J. Carbon. 2007, 45(3), 618-623). The shape memory polymer was then heated to approximately 60° C. after which drop casting deposition was used to create a thin layer of CNTs. Drop casting is done by pipetting the CNT disperse solution on top of the heated shape memory polymer. The shape memory polymer was then left to dry in a closed container for two hours. In the case of using aqueous CNTs, after the shape memory polymer is dried, it is further washed with an aqueous solvent to remove any surfactants present on the shape memo...

example 3

Biaxial or Multi-axial Shrinkage of a CNT Thin Film to Produce a Wrinkled Structure

[0176]One embodiment is a process to densify a CNT thin film to produce wrinkled structure using polyolefin, a chemically resistant shape memory polymer. This was accomplished by first dispersing CNTs (0.05% wt / v) in a solution of chloroform. CNTs were sonicated for 30 minutes in an ice bath and centrifuged at 10,000 rpm for one hour. This process is also possible in aqueous solution. For example, CNTs can be dispersed into an aqueous solvent when a surfactant, such as sodium dodecyl sulfate (SDS), is present (Yu, J.; Grossiord, N.; Konin, C. E.; Loos, J. Carbon. 2007, 45(3), 618-623). The shape memory polymer was then heated to approximately 60° C. after which drop casting deposition was used to create a thin layer of CNTs. Drop casting is done by pipetting the CNT disperse solution on top of the heated shape memory polymer. The shape memory polymer was then left to dry in a closed container for two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com