Method, container and uses for converting biomass materials into soluble substances by one-step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

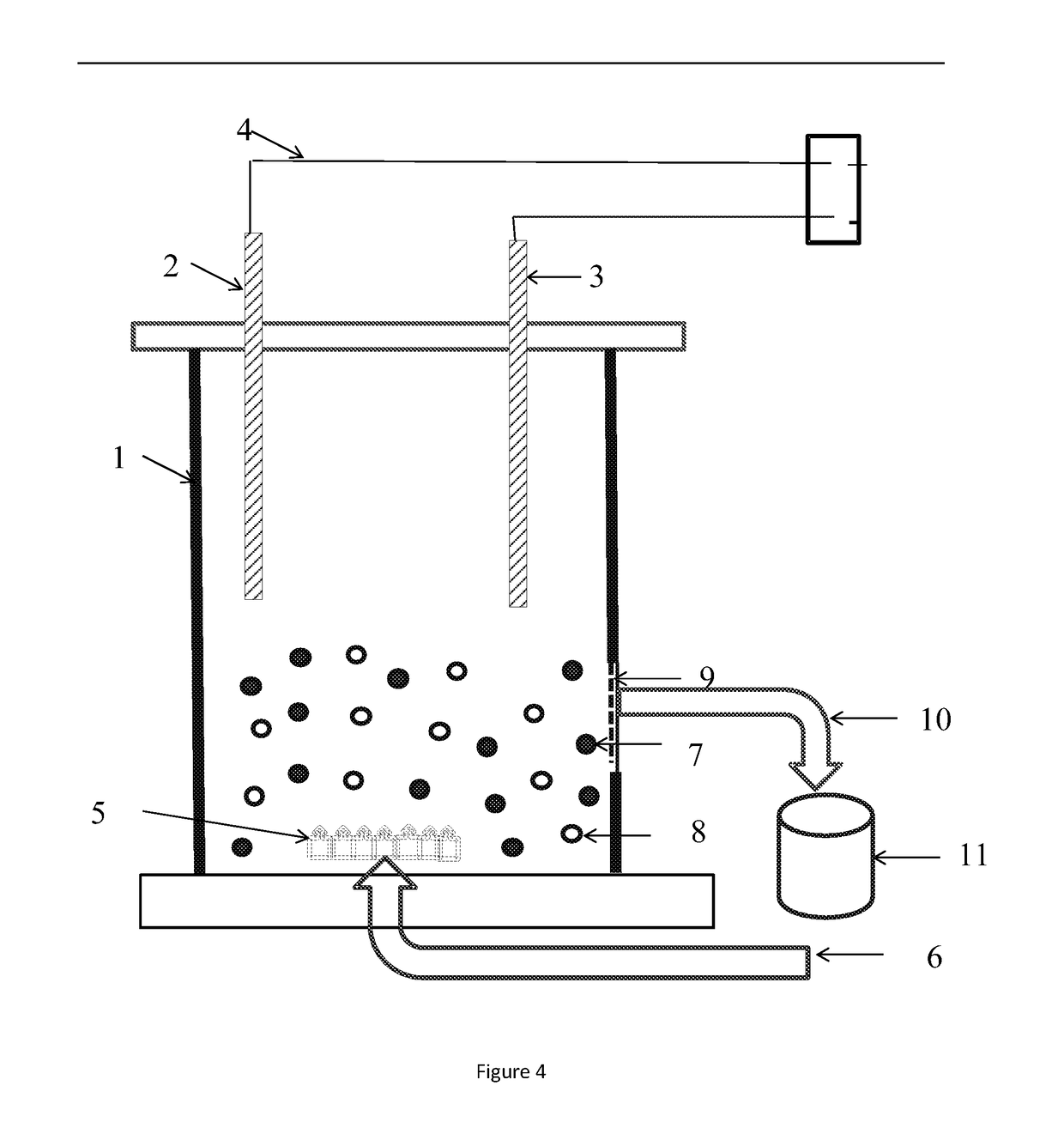

Method used

Image

Examples

embodiment 1

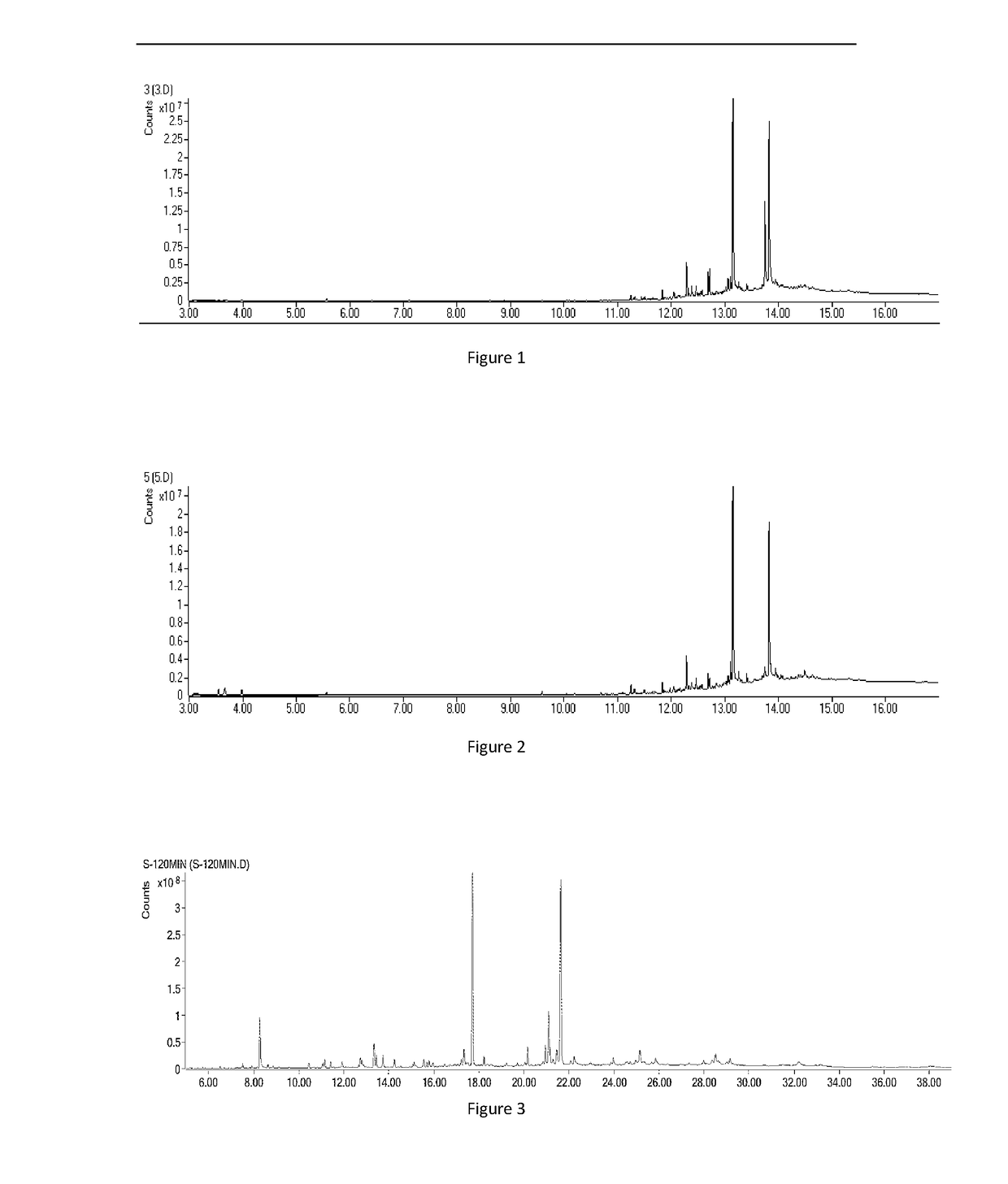

[0074]With the method above, an experiment was carried out in the present invention by using the following conditions. current intensity: 0.3 A; reacting at different times; molarity and volume ratio of NaCl: 0.4 mol / L; mass / volume ratio of the particle electrodes in the electrolyte: 2%; mass / volume ratio of the lignin in the electrolyte: 5%; After reaction, samples were taken and extracted by ethyl acetate and n-hexane. The varieties of the products were analyzed by GC-MS. The result of GC-MS showed the product mainly included two substances: hexadecanoic acid, methyl ester and 9-octadecenoic acid, methyl ester. The main products from the biomass materials were hexadecanoic acid and 9-octadecanoic acid. This was because products need to be methyl esterified before the GC-MS analysis, and the real products should accordingly remove methyl ester moieties. Yields and conversion rates of every product were analyzed by GC-MS. The gas detection diagram was shown in FIG. 1, and the variet...

embodiment 2

[0075]With the method above, an experiment was carried out in the present invention by using the following conditions. current intensity: 0.3 A; molarity and volume ratio of NaCl: 0.2 mol / L; mass / volume ratio of the particle electrodes in the electrolyte: 2%; mass / volume ratio of the lignin in the electrolyte: 5%; After different reaction time, samples were taken and extracted by ethyl acetate and n-hexane. Yields and conversion rates of every product were analyzed by GC-MS, as shown in table 3. The gas detection diagram was shown in FIG. 2.

TABLE 3conversion ratios of two products in the present embodimenthexadecanoic9-octadecenoicproductacidacidconversion rate (57.5 min)24.2%23.4%

embodiment 3

[0076]With the method above, an experiment was carried out in the present invention by using the following conditions. current intensity: 0.3 A; molarity and volume ratio of NaCl: 0.4 mol / L; mass / volume ratio of the particle electrodes in the electrolyte: 3%; lignin: 5%; After different reaction time, samples were taken and extracted by ethyl acetate and n-hexane. Yields and conversion rates of every product were analyzed by GC-MS, as shown in table 4. The gas detection diagram was shown in FIG. 3.

TABLE 4conversion ratios of two products in the present embodimenthexadecanoic9-octadecenoicproductacidacidconversion rate (90 min)18.3%20.7%conversion rate (120 min)27.6%23.7%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com