Ion Filter

a technology of ion filter and filter plate, which is applied in the direction of particle separator tube details, electric discharge tubes, beam/ray focussing/reflecting arrangements, etc., can solve the problems of etching structure damage, lack of ideal ratio of ions to numbers, and production of plasma, so as to reduce the etch selectivity of the mask, reduce the erosion of the mask, and increase the bias of the aperture plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

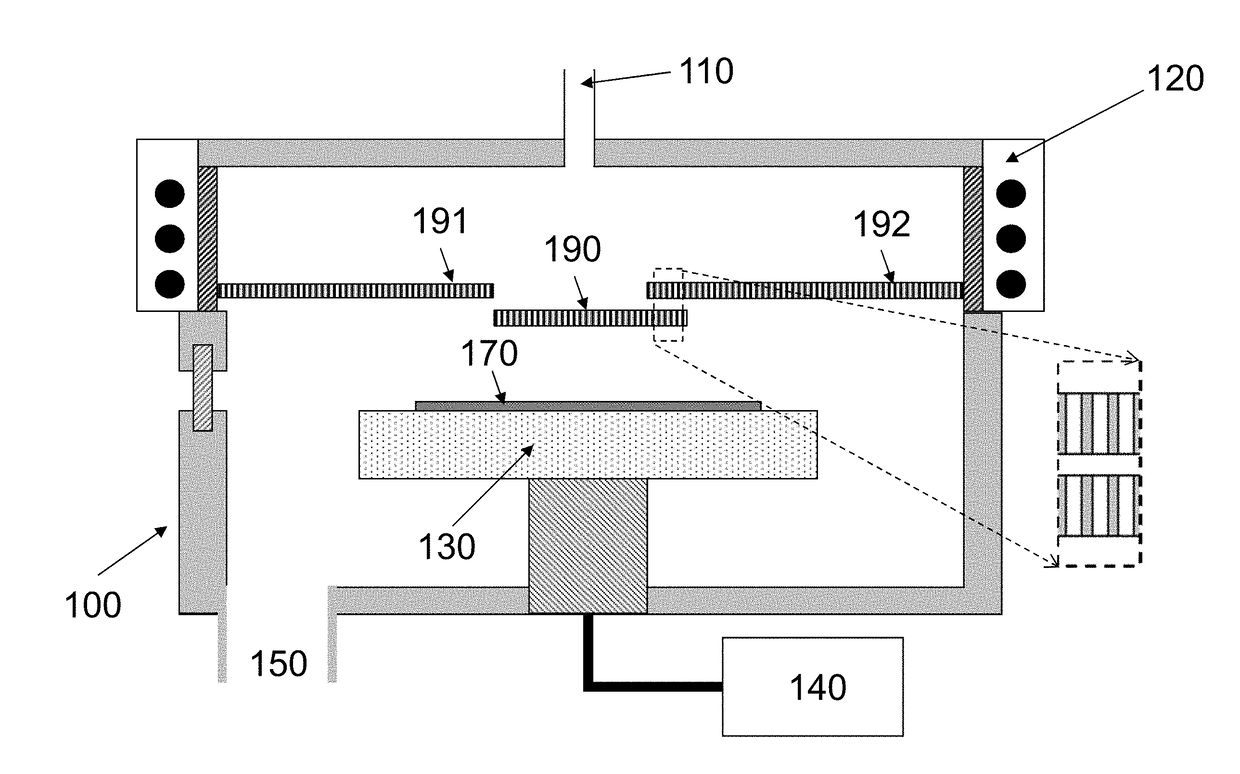

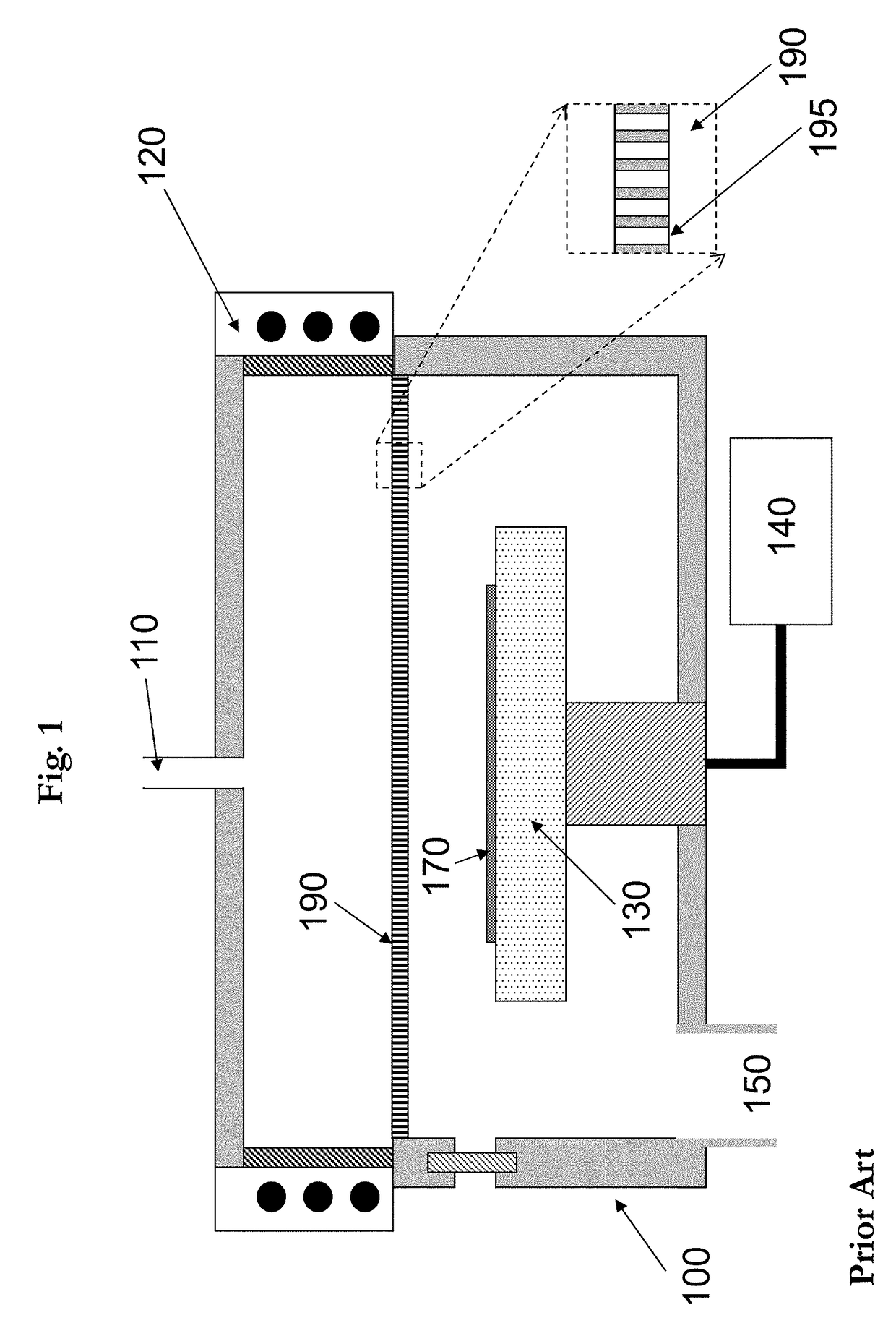

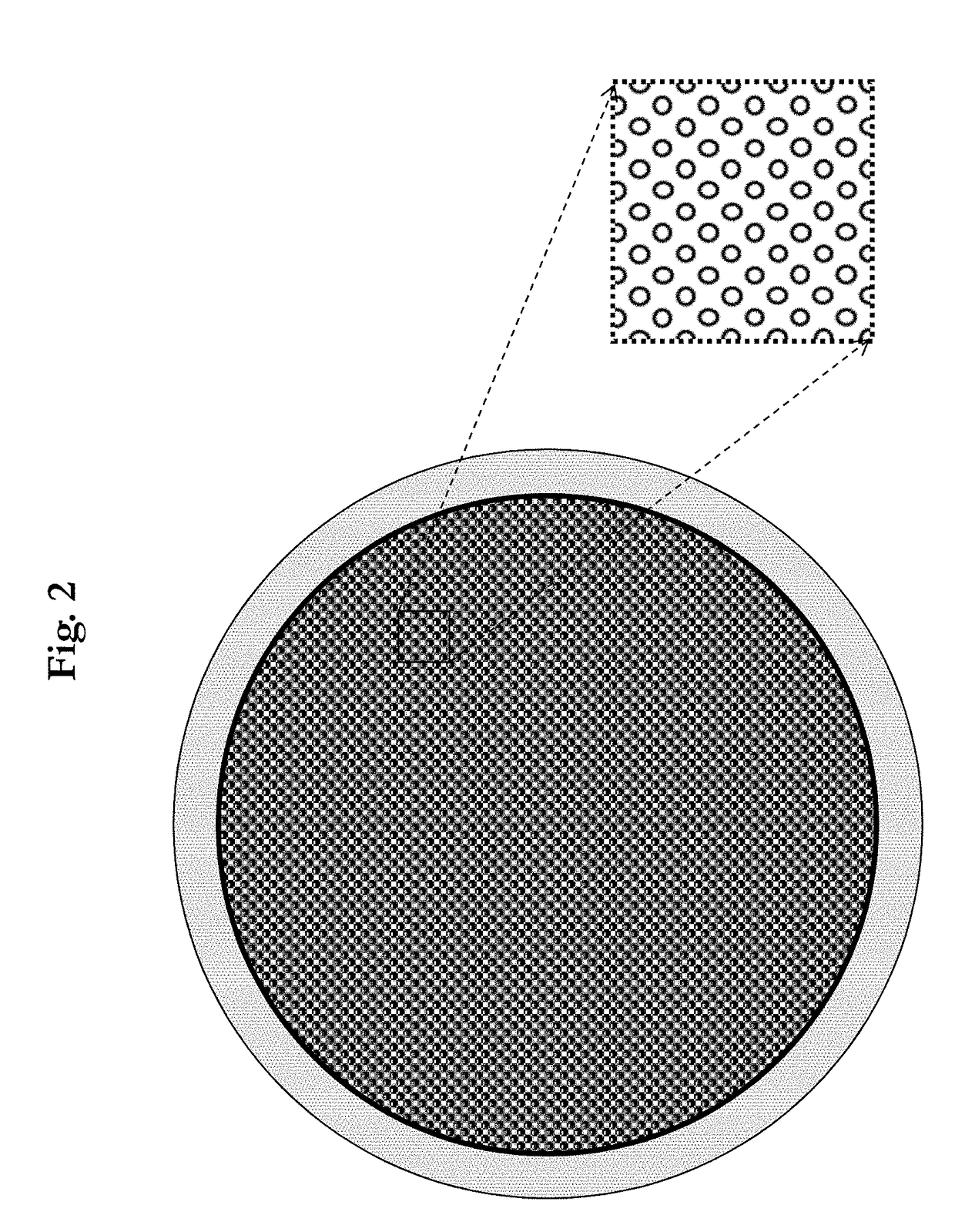

[0046]The present invention provides several method embodiments for using ion filtering to adjust the number of ions delivered to a substrate. All of the method embodiments of the present invention have a process chamber that is operatively connected to a plasma source wherein the substrate is placed on a substrate support that is provided within the process chamber. All of the method embodiments of the present invention can have the substrate further comprise a semiconductor wafer on tape on a frame. All of the method embodiments of the present invention generate a plasma using the plasma source that is used to process the substrate in the process chamber.

[0047]In all of the method embodiments described herein, when an aperture plate is divided into two or more physically separate zones that may be separately biased, it is possible by adjusting the bias voltage to a different level in the two or more aperture plate zones to adjust the degree of ion filtering to a greater or lesser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com