Distributed feedback laser and preparation method thereof

A distributed feedback, laser technology, applied in the field of lasers, can solve the problems affecting laser performance and practical application, large aspect ratio of etched grating, mode instability, etc., to reduce the etching selection ratio, improve device performance, reduce The effect of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

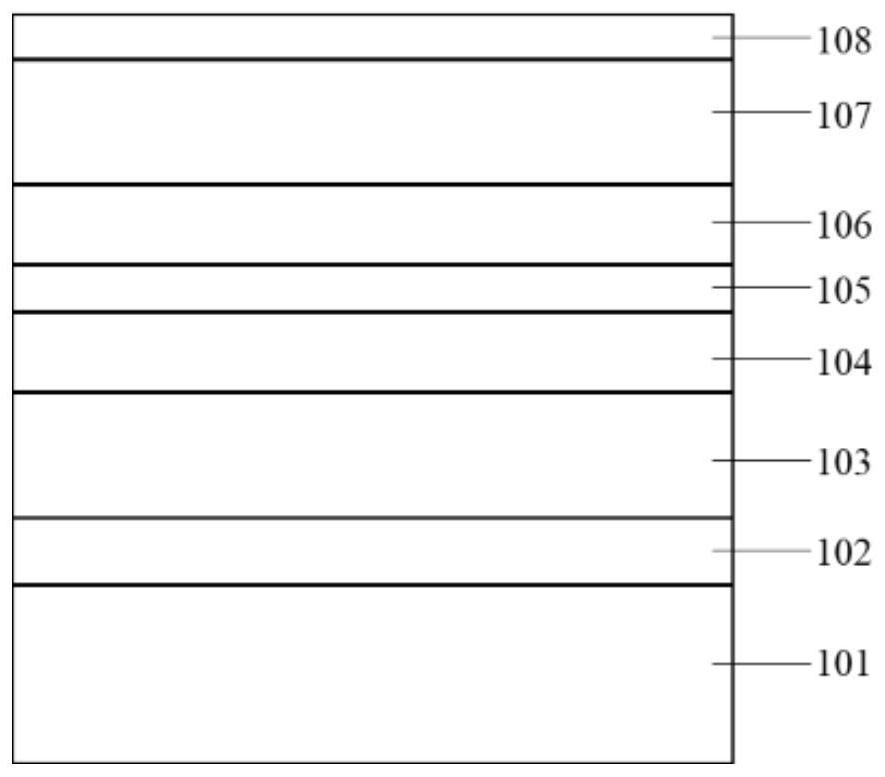

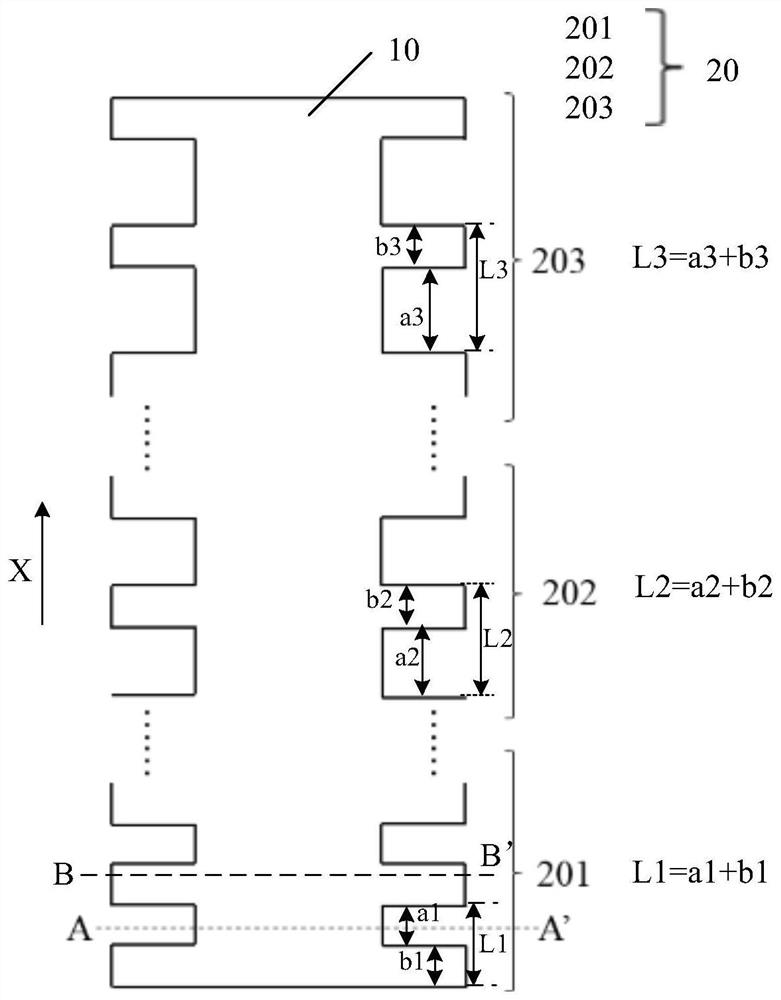

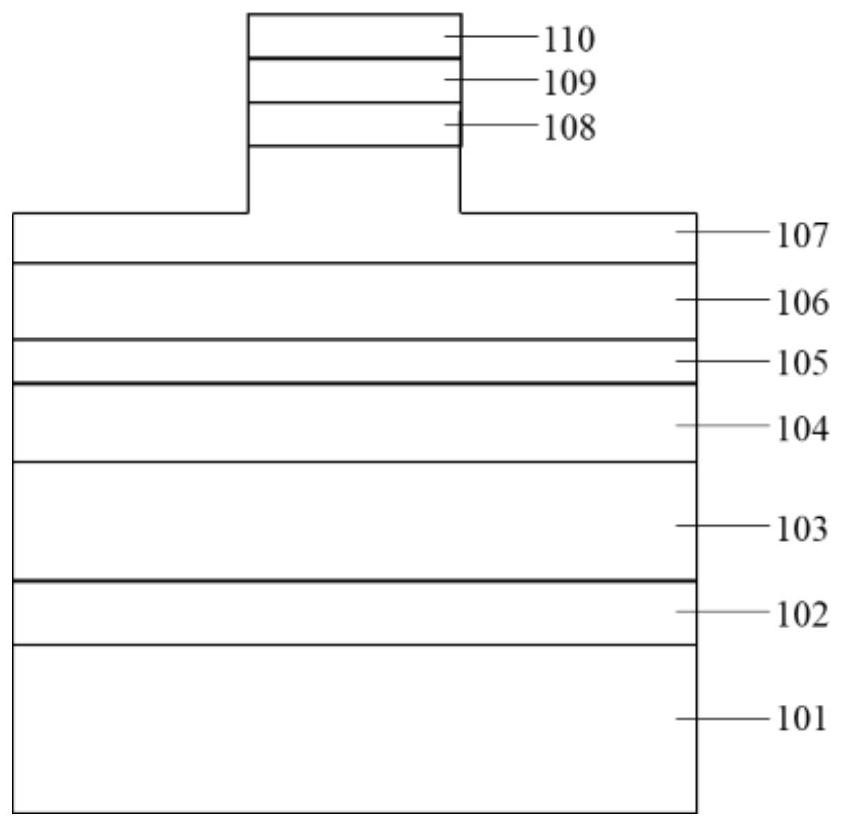

[0059] An embodiment of the present invention provides a distributed feedback laser. figure 1 A cross-sectional schematic diagram of an epitaxial structure of a distributed feedback laser provided by an embodiment of the present invention; figure 2 A surface schematic diagram of an epitaxial structure after a distributed feedback laser has etched a ridge structure and a grating structure group provided for an embodiment of the present invention; image 3 for figure 2 Schematic cross-sectional view of the ridge structure along the AA' direction in ; Figure 4 for figure 2 Schematic cross-sectional view of the grating structure group along the BB' direction in . Such as Figure 1-4 As shown, the distributed feedback laser includes: a laser epitaxial structure, the laser epitaxial structure includes a substrate 101 and a multi-layer epitaxial layer located on one side of the substrate 101, the multi-layer epitaxial layer includes an intermediate epitaxial layer and an inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com