Mold and method for manufacturing the same

a technology of molding and molding, applied in the field of molding, can solve the problems of difficult to form a fine surface roughness on a large area of a flat surface or a curved surface, and difficult to adjust the shape of the fine surface roughness, and achieve the effect of desired performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

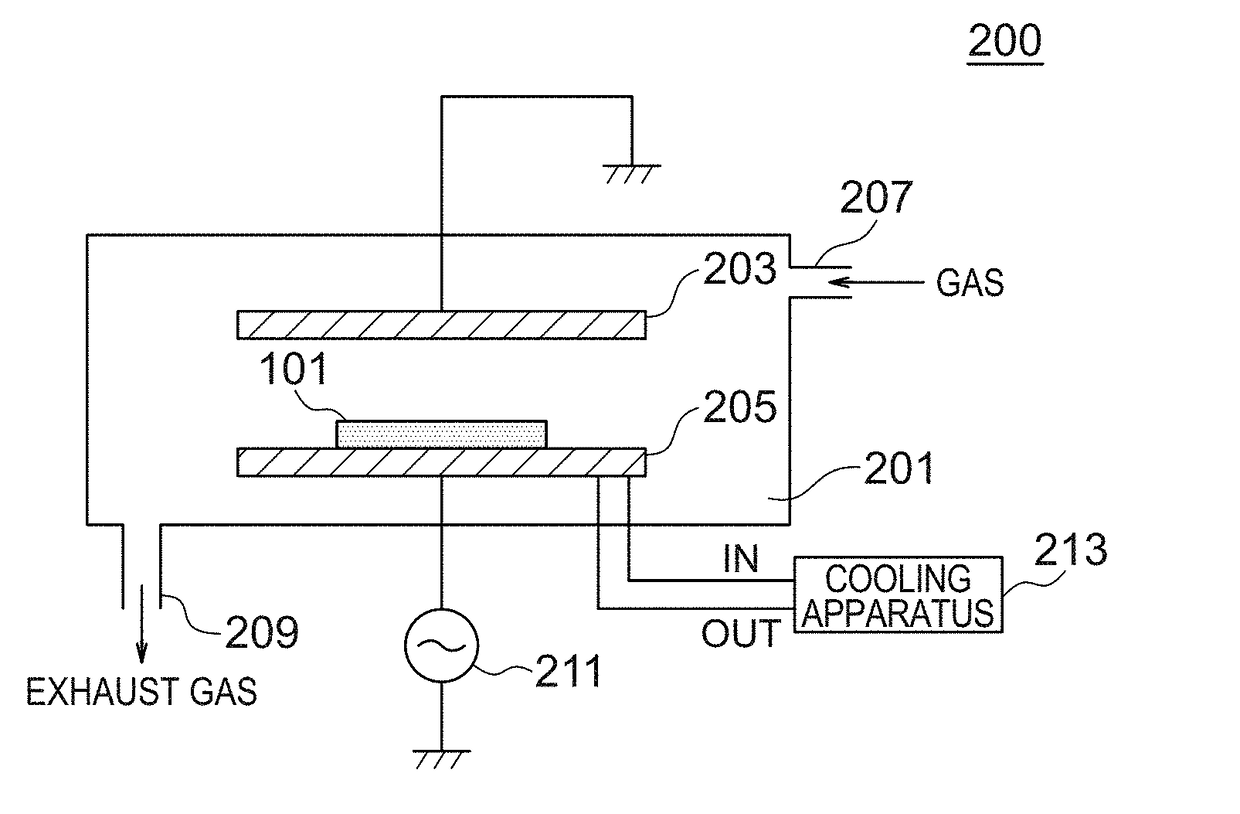

[0047]FIG. 1 is a flowchart showing a method for manufacturing a mold according to an embodiment of the present invention. In the present method, at first a fine surface roughness is formed on a surface of a base material by reactive ion-etching, and then the fine surface roughness formed in the way described above is processed by ion beam etching. The flowchart of FIG. 1 illustrates a method by which a mold for an anti-reflective structure is manufactured.

[0048]In step S1010 of FIG. 1, processing conditions of reactive ion-etching are determined. The processing conditions of reactive ion-etching will be described in detail later.

[0049]In step S1020 of FIG. 1, the base material is made to undergo reactive ion-etching.

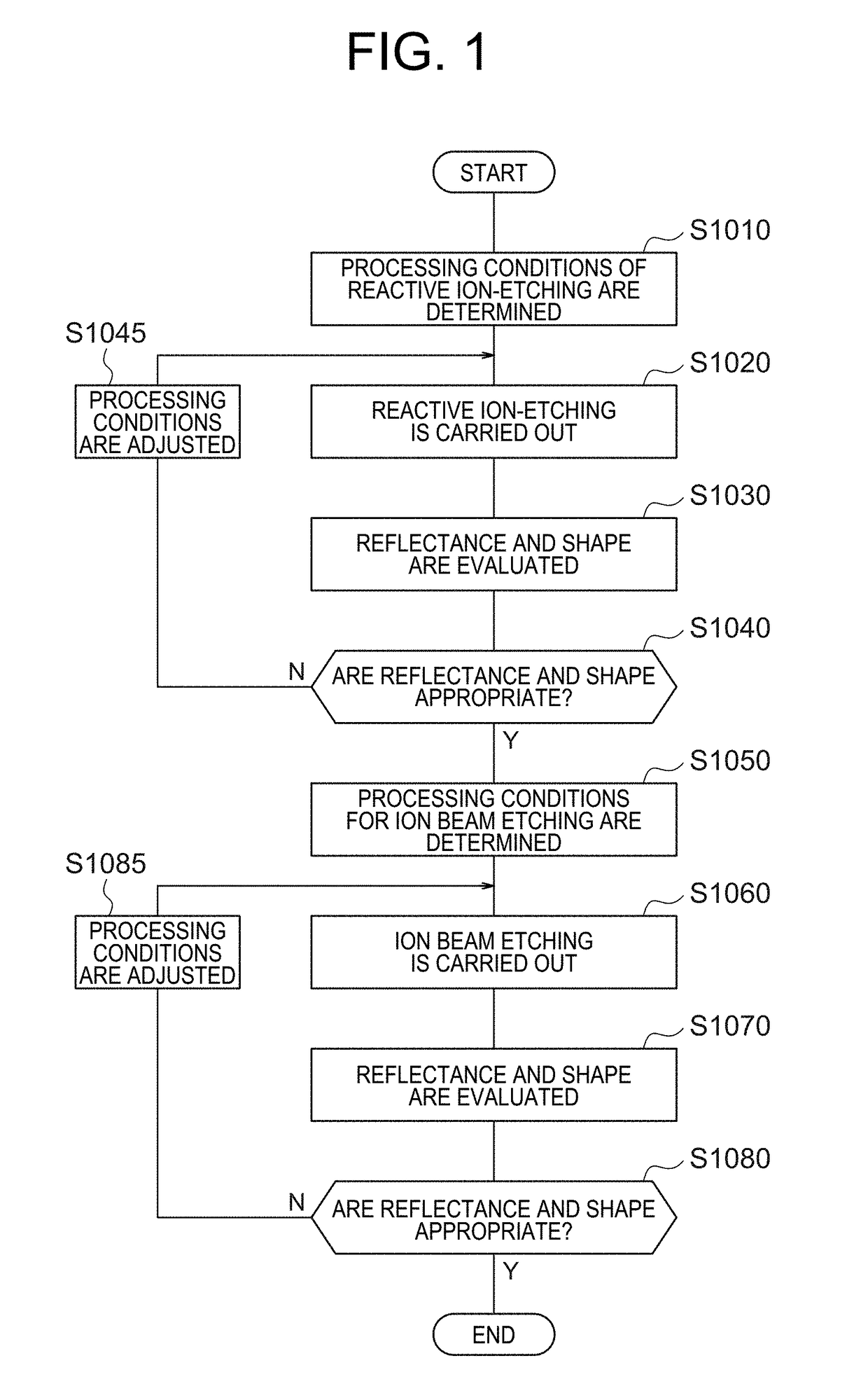

[0050]FIG. 2 is a diagram showing constitution components in a reactive ion etching apparatus 200 used for manufacturing a mold provided with a fine surface roughness. The reactive ion etching apparatus 200 has an enclosure 201. The enclosure 201 is evacuated and then s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com