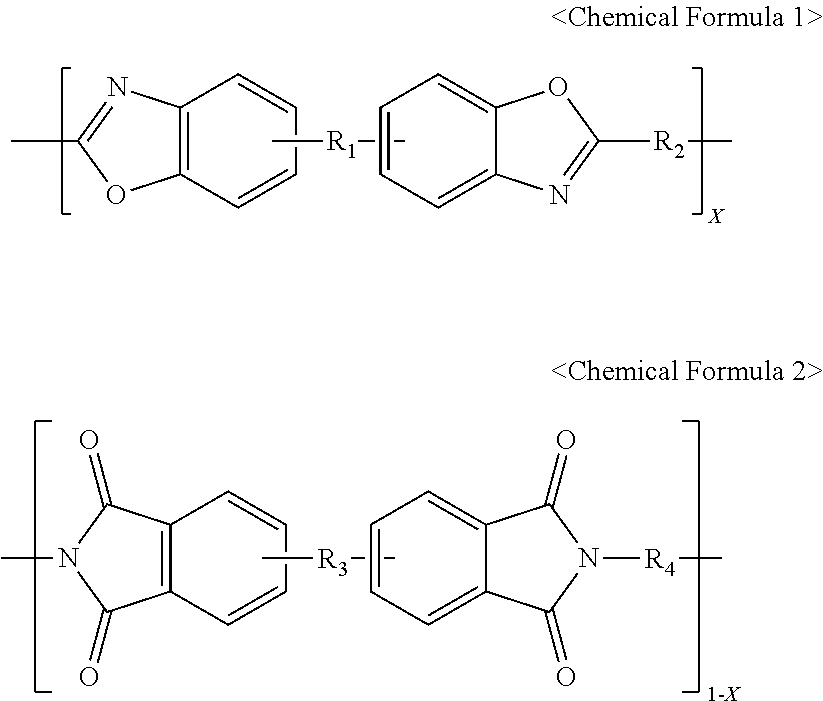

Polyimide-polybenzoxazole precursor solution, polyimide-polybenzoxazole film, and preparation method therefor

a polyimide and polybenzoxazole technology, applied in the field of polyimidepolybenzoxazole precursor solution, polyimidepolybenzoxazole film, and the same, can solve the problems of reducing light transmittance, increasing birefringence, and difficult to utilize it for optical members, and achieves high optical properties, superior heat resistance and birefringence, and the effect of increasing the number of conjugated double bonds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0077]After a 500 ml reactor equipped with a stirrer, a nitrogen injector, a dropping funnel, a temperature controller and a condenser was purged with nitrogen, 284.867 g of N-methyl-2-pyrrolidone (NMP) was placed in the reactor and 7.398 g (0.022 mol) of 6FAP was dissolved therein, after which 4.466 g (0.022 mol) of IPC was added thereto at 10° C. and allowed to react for 2 hr. Thereafter, 28.180 g (0.088 mol) of TFDB was dissolved therein, after which 15.535 g (0.053 mol) of BPDA was added thereto and allowed to react for 5 hr, and 15.638 g (0.035 mol) of 6FDA was added thereto. The resulting solution was maintained at room temperature and allowed to react for 18 hr, thereby obtaining a solution having a solid content of 20 wt % and a viscosity of 202 poise. After termination of the reaction, the obtained solution was applied onto a stainless steel plate, cast to a thickness of 10˜20 μm, dried with hot air at 80° C. for 20 min, at 120° C. for 20 min and at 300° C. for 10 min, grad...

example 2

[0078]After a 500 ml reactor equipped with a stirrer, a nitrogen injector, a dropping funnel, a temperature controller and a condenser was purged with nitrogen, 272.971 g of N-methyl-2-pyrrolidone (NMP) was placed in the reactor and 14.795 g (0.044 mol) of 6FAP was dissolved therein, after which 8.933 g (0.044 mol) of IPC was added thereto at 10° C. and allowed to react for 2 hr. Thereafter, 21.135 g (0.066 mol) of TFDB was dissolved therein, after which 11.651 g (0.040 mol) of BPDA was added thereto and allowed to react for 5 hr, and 11.728 g (0.026 mol) of 6FDA was added thereto. The resulting solution was maintained at room temperature and allowed to react for 18 hr, thereby obtaining a solution having a solid content of 20 wt % and a viscosity of 187 poise. After termination of the reaction, the obtained solution was applied onto a stainless steel plate, cast to a thickness of 10˜20 μm, dried with hot air at 80° C. for 20 min, at 120° C. for 20 min and at 300° C. for 10 min, gra...

example 3

[0079]After a 500 ml reactor equipped with a stirrer, a nitrogen injector, a dropping funnel, a temperature controller and a condenser was purged with nitrogen, 261.075 g of N-methyl-2-pyrrolidone (NMP) was placed in the reactor and 22.193 g (0.066 mol) of 6FAP was dissolved therein, after which 13.399 g (0.066 mol) of IPC was added thereto at 10° C. and allowed to react for 2 hr. Thereafter, 14.090 g (0.044 mol) of TFDB was dissolved therein, after which 7.767 g (0.026 mol) of BPDA was added thereto and allowed to react for 5 hr, and 7.819 g (0.018 mol) of 6FDA was added thereto. The resulting solution was maintained at room temperature and allowed to react for 18 hr, thereby obtaining a solution having a solid content of 20 wt % and a viscosity of 161 poise. After termination of the reaction, the obtained solution was applied onto a stainless steel plate, cast to a thickness of 10˜20 μm, dried with hot air at 80° C. for 20 min, at 120° C. for 20 min and at 300° C. for 10 min, grad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com