Apparatus, system and methods for improved vertical farming

a technology of vertical farming and apparatus, applied in the field of apparatus, system and methods for improving vertical farming, can solve the problems of affecting the success of traditional outdoor farming crops, and wasting as much as 30% of harvested crops, so as to reduce the cost and complexity of existing vertical structure designs, reduce the amount of human labor needed, and simplify the coring process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

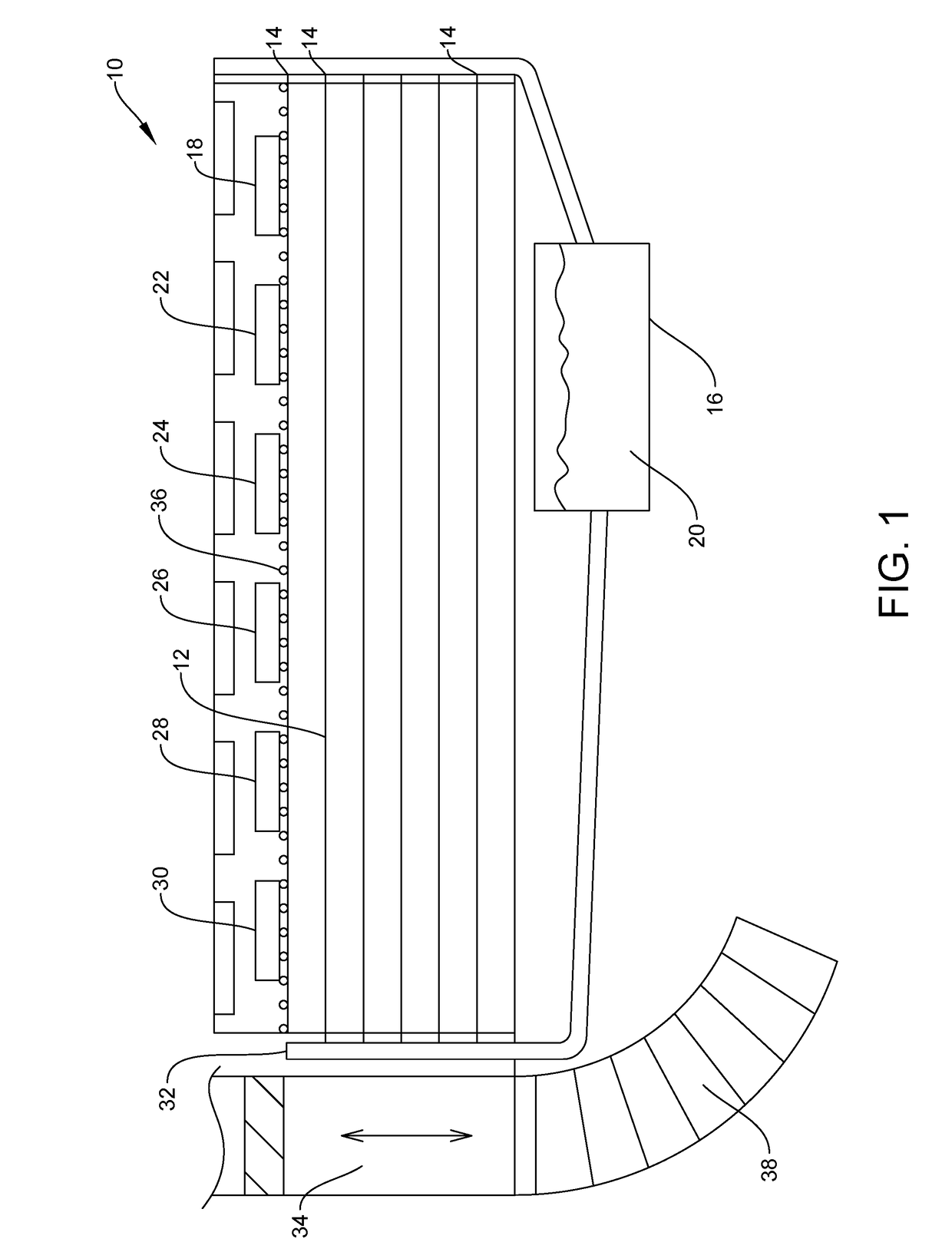

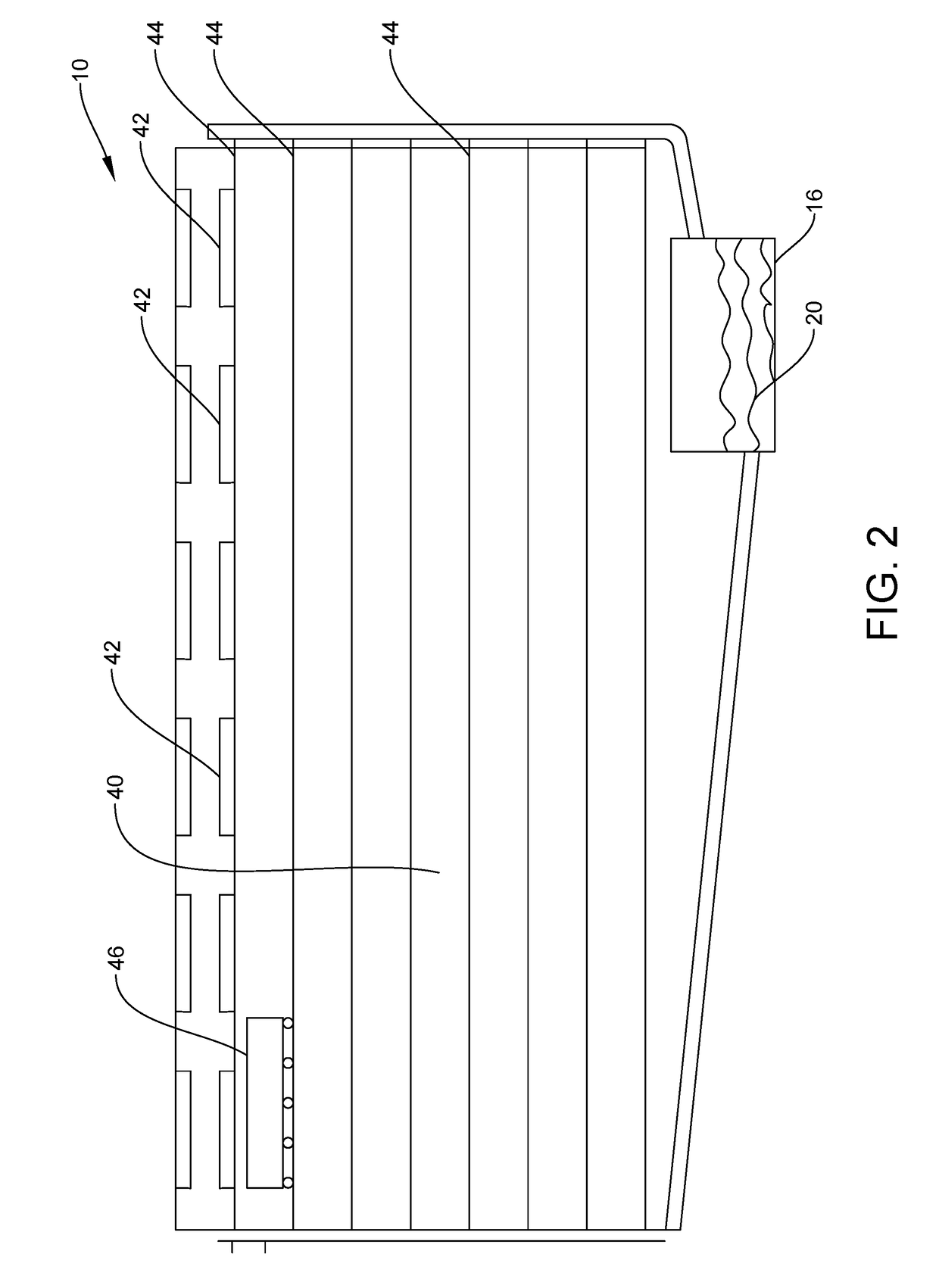

[0059]Referring to the drawings, wherein like reference numerals refer to the same or similar features in the various views, the present disclosure pertains to an improved vertical farming system for autonomously growing edible plants, using improved stacking, storage and shelving units are configured to allow for easy access and gravity-based irrigation and feeding, alone or in combination with an improved shuttle system for autonomous rotation of the growing plants throughout the improved vertical farming system.

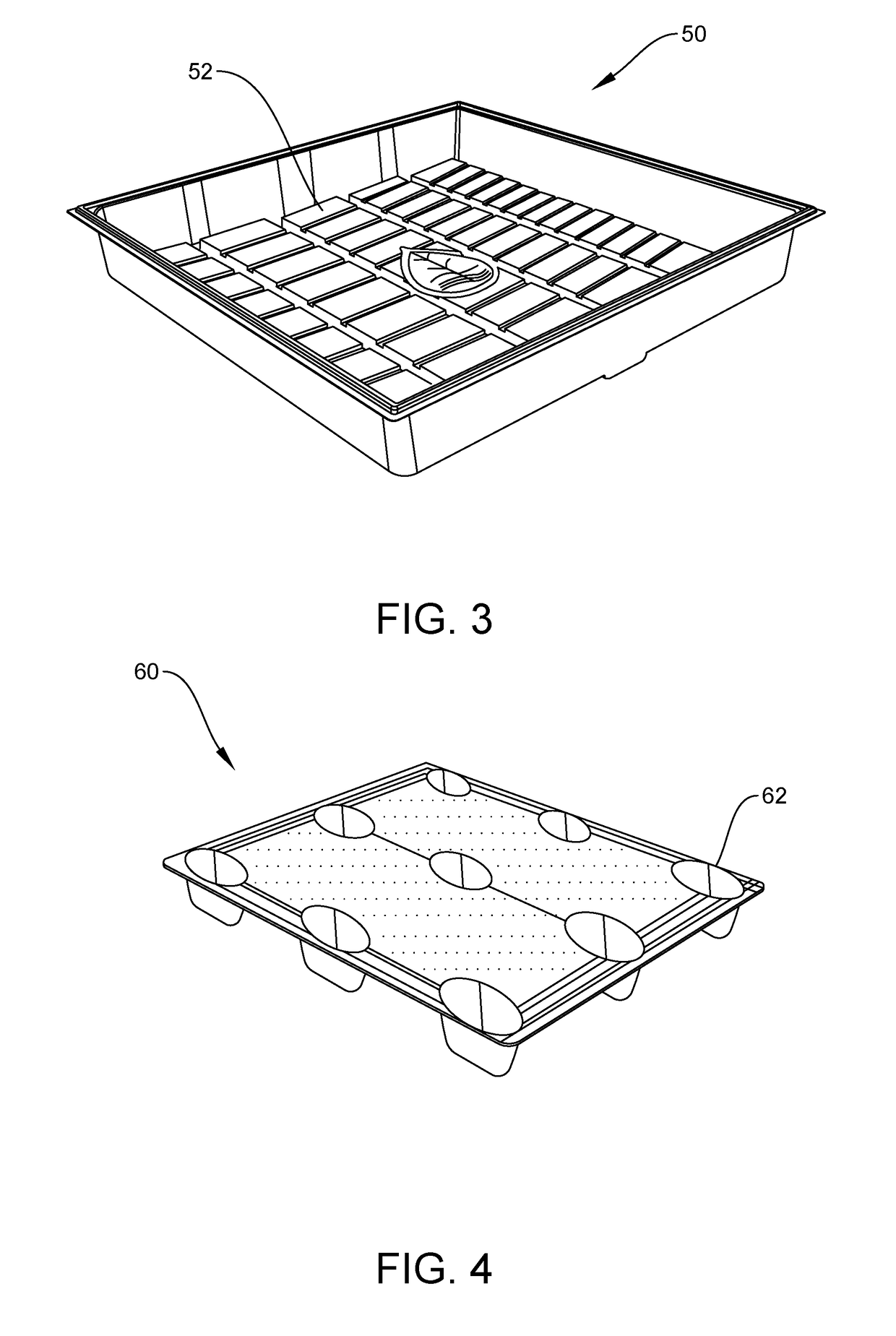

[0060]The innovative vertical farming system further comprises novel grow trays or plant-growing pallets, and incorporates camera systems, including telescoping arms, camera vehicles and autonomous smart drones, fly preprogrammed routes; all with 3D and multispectral cameras (and other recording instruments) to photograph and record the growing plants and obtain vertical farming metrics, as necessary. The images and other data recorded being automatically sent to a databas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com