Waveguides for use in sensors or displays

a waveguide and sensor technology, applied in the field of waveguides, can solve the problems of loss of elastomers in optical waveguides and more light loss to an environment, and achieve the effect of increasing the deformation of optical waveguides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0183]A monolithic actuator was formed using rotational casting and without encapsulation. Previously, each chamber of the actuator was not connected after rotational casting. To actuate the whole actuator together, an extra step was required. This rotational casting technique interconnects of each chamber during rotational casting so that no extra steps are required for actuation.

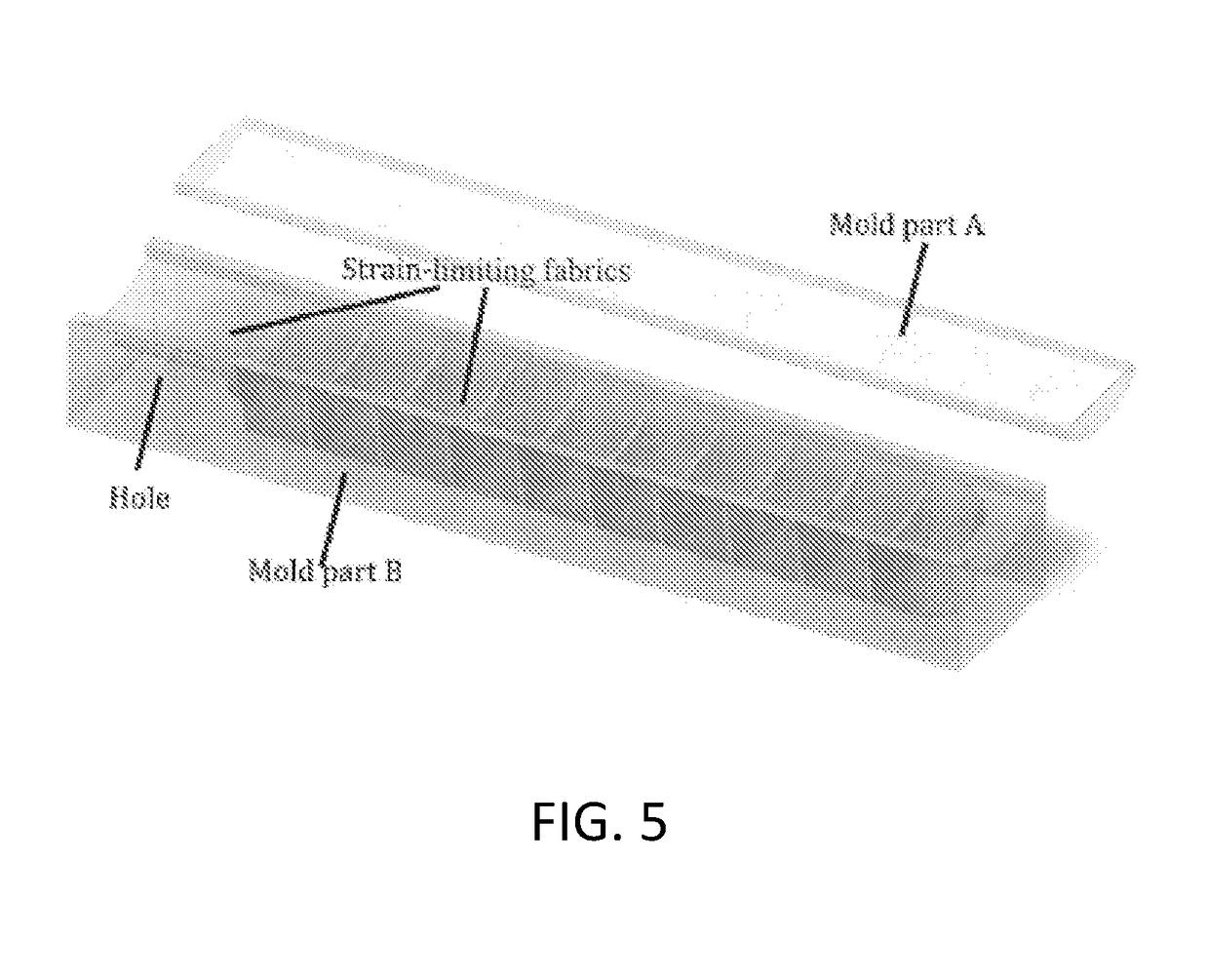

[0184]FIG. 5 is a perspective view of a mold used for rotational casting of a soft actuator. Mold part B was filled with pre-elastomers and strain-limiting fabrics were put both on the top and along the bottom side surfaces. The cap (mold part A) was closed and the assembled mold was fixed on a rotational casting machine. The mold was rotated for three hours non-stop. A steel wire was inserted through the small hole of the mold. The mold was then placed in an oven to fully cure. The mold was later taken out of the oven and the wire removed. The actuator was then peeled off and tested.

[0185]Using this techn...

example 2

[0186]The orthotic of FIG. 7 has the following features: (1) low stiffness when deflated, which enables easy movement of the wearer's finger; (2) high force / torque generation; (3) repeatable performance from its manufacturing technique (rotational casting); (4) integrated curvature sensor with high repeatability and resolution; (5) compatible bending range for finger motions. The finger exoskeleton had a length of 110 mm, an effective length of 70 mm, a range of motion from 0° to 105°, provided 0 kPa to 270 kPa pressure, and had a tip force between 0 N and 5 N.

[0187]The fabrication process for the orthotic with embedded curvature sensor includes three stages: (1) fabricate the internal actuator (FIG. 8), (2) shape and pattern the sensor's light guide (FIG. 9), and (3) assemble and cast into a complete orthotic (FIG. 10).

[0188]The internal actuator is a monolithic structure having a series of hollow chambers with nylon mesh incorporated in one side to program a bending mode of inflat...

example 3

[0204]Due to their persistent use and complex and delicate forms, hands and fingers are among the most vulnerable human parts. Over 3 million people in the United States suffer from hand or forearm disabilities, and worldwide hand injuries account for one third of all work injuries. Due to the importance of hands and prevalence of hand issues, there has been an increasing effort toward developing hand orthotics. Active hand orthoses have been shown to assist in rehabilitation training and the restoration of partial hand function. Many orthoses use mechanical compliance to ensure safety and to reduce control complexity. Mechanically compliant actuators use under-actuated linkages or low stiffness materials and structures (e.g., rubbers and flexible wires). Of these options, those composed of elastomeric materials tend to be comfortable because their very low elastic modulus (10 kPa<G′<1 MPa) is similar to that of human skin (˜100 kPa).

[0205]Orthotic systems made of elastomers and pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com