Ferromagnetic Resonance (FMR) Electrical Testing Apparatus for Spintronic Devices

a testing apparatus and magnetic resonance technology, applied in the direction of instruments, material analysis, measurement using electron paramagnetic resonance, etc., can solve the problem of preventing wide acceptance of fmr, and achieve the effect of reliable scanning fmr measurement system, convenient implementation, and convenient configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

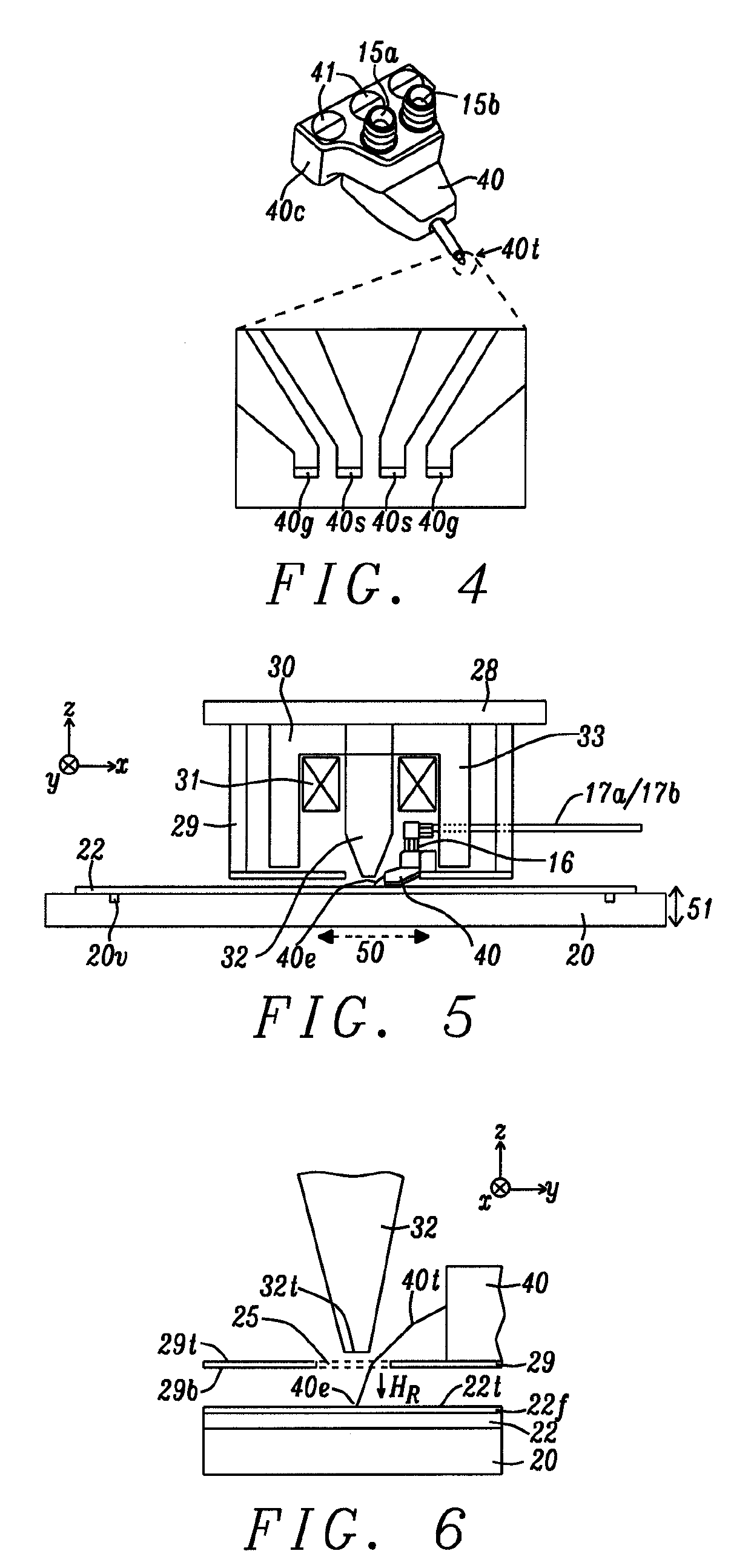

[0043]The controller 11 has an electrical connection 42b to a RF generator 48 that provides a plurality of microwave frequencies through link 42c to a first RF connector (not shown) on RF probe 40. In some embodiments, the RF generator produces a first microwave frequency (f1) in the range of 1 to 20 GHz. However, the present disclosure anticipates inserting a frequency multiplier module (not shown) between the RF generator and RF probe that adjusts f1 to a second RF frequency (f2) where f2>f1. For example, when f1=20 GHz, the frequency multiplier module may be an active frequency doubler that adjusts f1 to f2 where f2=40 GHz. RF frequencies below 1 GHz are not practical for the purpose of inducing a FMR condition in the magnetic film.

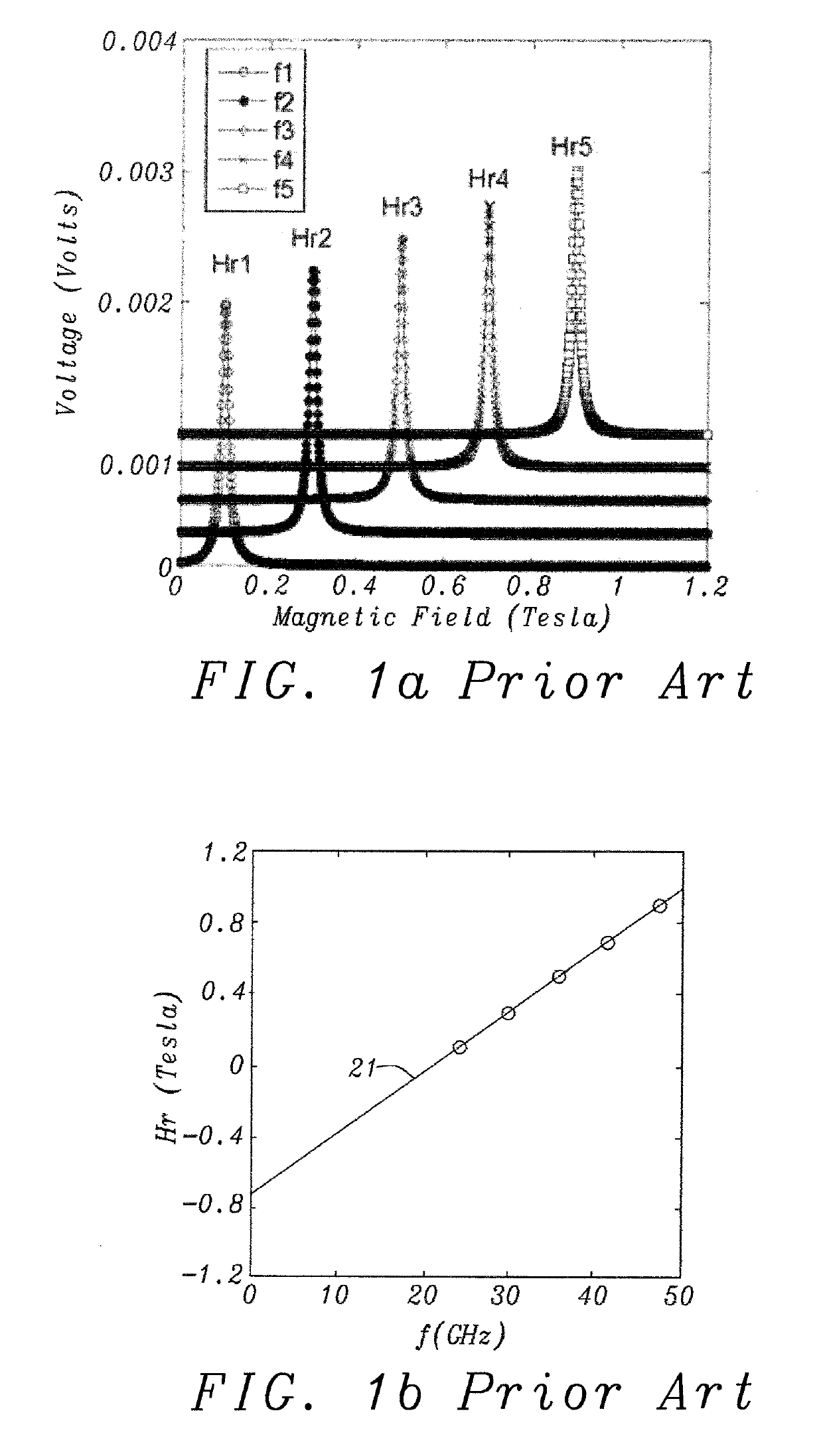

[0044]In a preferred operating mode for a FMR measurement, the applied magnetic field is varied (swept from a minimum to a maximum value) at a constant microwave frequency. The FMR measurement is preferably repeated by sweeping the magnetic field succ...

second embodiment

[0049]Referring to FIG. 7, the scanning FMR measurement system of the present disclosure is shown that retains all of the features of the previous embodiment except the magnetic assembly comprises two magnetic poles 32a, 32b that are each surrounded by Cu coils 31, and are positioned on either side of the RF probe tip 40e, and proximate to the WUT 22 but not touching the magnetic film (not shown). Here a first pole may apply the in-plane magnetic field HR while a second pole may serve as the return pole. Thus, the pole configuration produces a magnetic field HR in the plane of the magnetic film proximate to the (xn, yn) coordinate where the RF probe tip contacts the top surface thereof. Applied RF frequencies during FMR measurements for this magnetic assembly configuration may be in the range of 0.01 to 100 GHz.

[0050]Referring to FIG. 8, a schematic drawing of a scanning FMR measurement system configured for a RF signal transmission mode is depicted according to a first embodiment o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com