Stability of polyurethane polyol blends containing halogenated olefin blowing agent

a technology of halogenated olefin and polyurethane, which is applied in the field of stabilizing thermosetting foam blends, can solve the problems of reduced shelf life of b-side composition of hydrocarbons such as pentane isomers, low energy efficiency, etc., and achieve the effect of improving shelf life stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

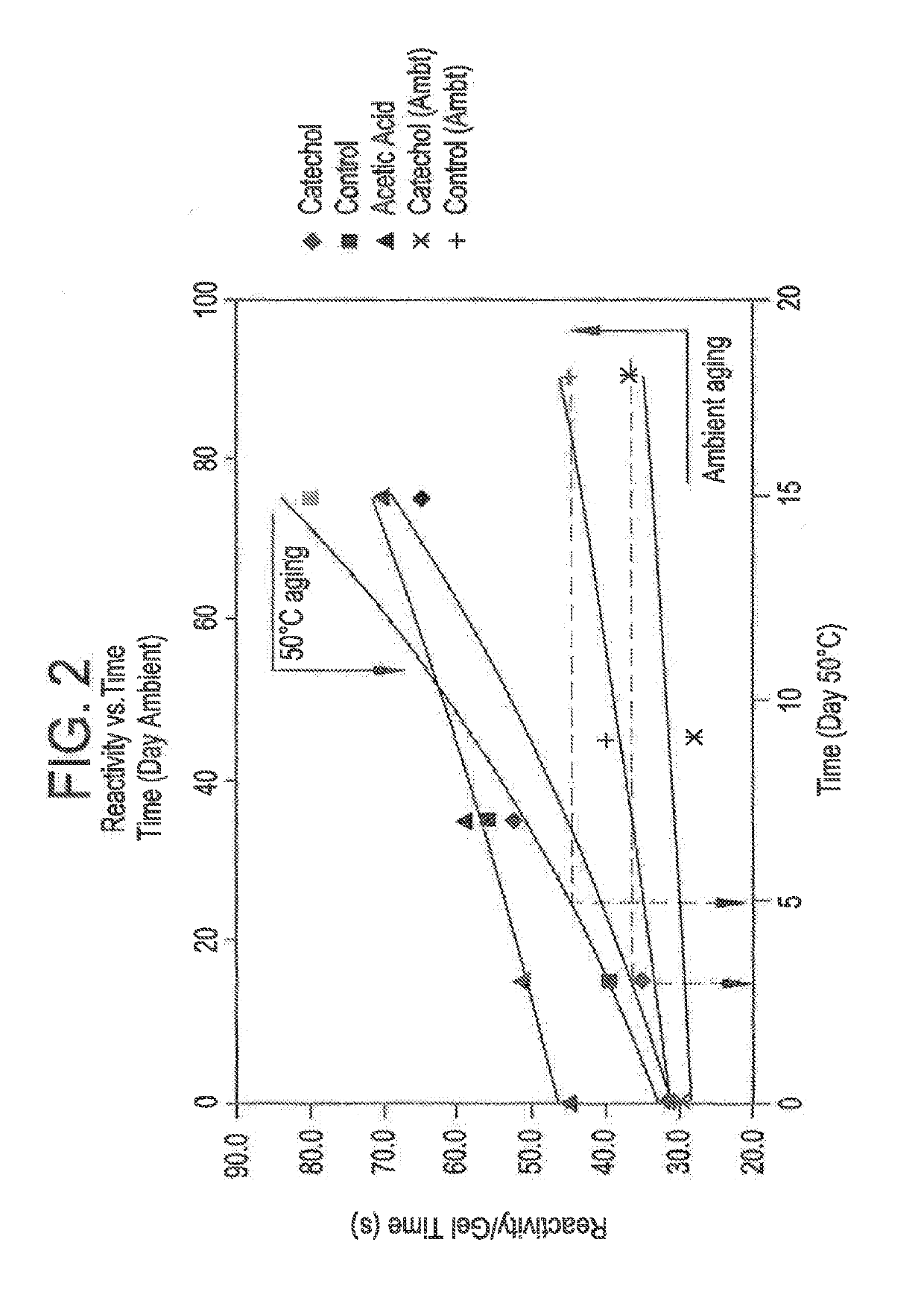

[0073]The invention is further illustrated by reference to the following Examples. The Examples show the improved stability imparted by the use of an antioxidant, such as 1,2-benzenediol, which imparts stability to the polyol pre-mix composition.

[0074]Tables 1A-1F lists the compositions of the Comparative Example and Examples 1-5. The Comparative Example and Example 1 comprised PolyCat® 5 (available from Air Products and Chemicals, Inc.), which contains pentamethyldiethylenetriamine. PolyCat® 5 does not comprise at least one ether and / or at least one hydroxyl group.

[0075]Examples 2-5 comprised JEFFCAT® amine catalysts, which are available from Huntsman Corp. JEFFCAT® Z-110 comprises N,N,N′-trimethylaminoethylethanolamine. JEFFCAT® ZR-70 comprises 2-(2-dimethylaminoethoxy)ethanol, JEFFCAT® ZF-10 comprises N,N,N′-trimethyl-N′-hydroxyethyl-bisaminoethylether. JEFFCAT® ZF-20 comprises bis(2-dimethylaminoethyl)ether.

TABLE 1AComposition of Comparative ExampleCOMPONENTwt % of Total B-sideV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling points | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com