Method To Produce Polymer Matrix Composites

a composite material and polymer technology, applied in the field of polymer matrix composite material production, can solve the problems of significant rate-limiting steps and substantial grinding time, and achieve the effects of advancing molecular weight, eliminating rate-limiting steps, and excellent thermal stability and tribological performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0028]This example demonstrates the production of discontinuous ATSP composites filled with chopped carbon fiber (other chopped fibers such as glass fibers work with the same principle). First, mix the two oligomers (CB and AB) with desired weight percentage of chopped carbon fiber. Then the blended components are loaded into a mold and placed in a hot press. The hot press is ramped to 270° C. and held for one hour with no pressure applied to the mold. After one hour, the temperature is ramped to 360° C. At 360° C., the pressure is increased to 27.6 MPa (4000 psi) and the sample is held for 2 hours and then allowed to cool. An example of a fully dense discontinuous composites produced by this method (as seen in FIG. 1) is one where the filler was ¼″ chopped IM-9 carbon fiber (by Hexcel) was 28 wt. % of the composite. Initial thermal experiments on this are described below.

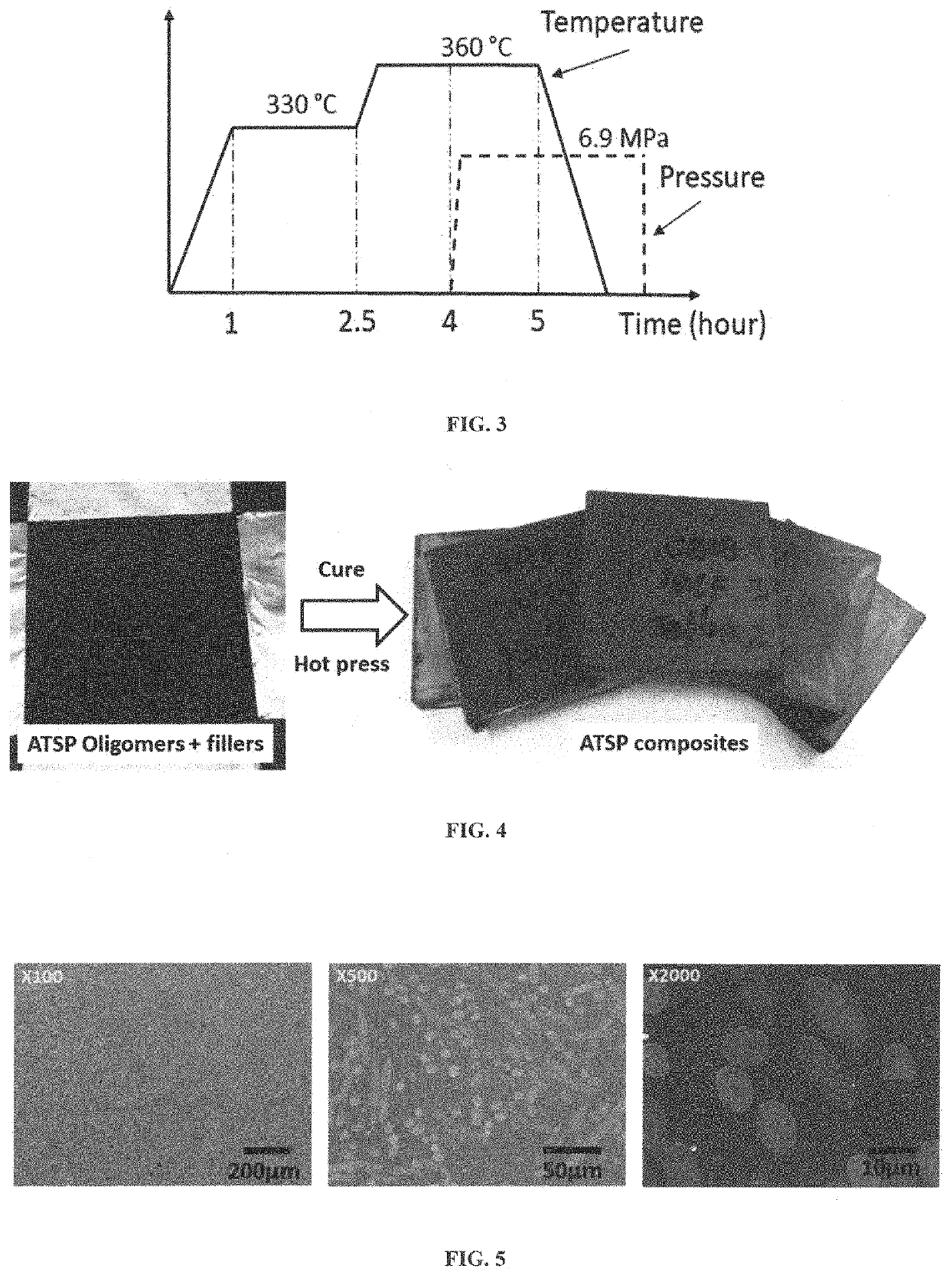

[0029]Thermal degradation of the composites was performed by a TGA (TA-2950) from room...

example 2

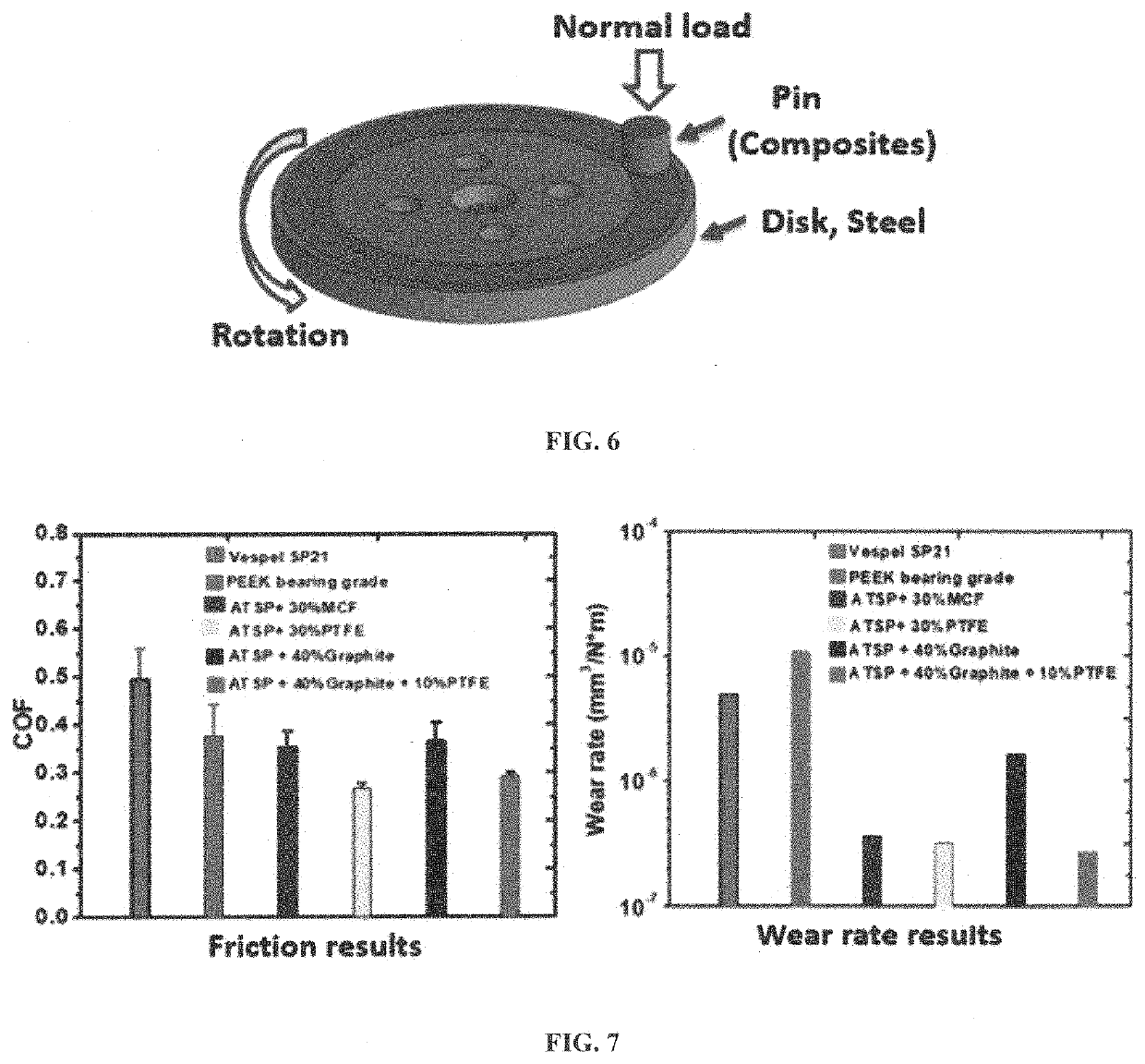

Different Fillers

[0031]As for Tribological applications, polymers in pure form as unfilled polymers may have high COF, high wear rate and poor mechanical properties, so they typically do not satisfy the tribological application needs. Thus, it is of great interest in producing composites or blended polymers by adding different fillers and reinforcements in the polymers, improving significantly their mechanical, thermal or tribological properties. In this example, we produced ATSP bearing grade composites by mixing ATSP oligomers with different fillers such as milled carbon fiber (Zoltek PX35MF0150), graphite powder, PTFE powder, carbon black, carbon nanotubes, and graphene nanoplatelets with different weight percentages. Examples of mixing ratio between ATSP and fillers that have been tried is listed in

[0032]Table 2.

TABLE 2Examples of mixing ratio between ATSP and fillersComposition of the mixtureNo.(CBAB is mixed of CB and AB oligomers with 50:50 weight ratio)1CBAB:milled carbon fi...

example 3

d—Metal Composite

[0035]Tilting pad bearings (for use in e.g. electrical submersible pumps) were fabricated using a filled composition of ATSP. A 304 stainless steel base was roughened by grit blast and subsequently cleaned via ultrasonication in isopropanol and then dried at 70° C. A mixed layer of CB and AB ground oligomeric powders (50:50 mass ratio, mesh size <90 um) were deposited via electrostatic powder deposition. The deposited coating was melted and cured via convection oven at 270° C.

[0036]The coated 304 base was inserted into a cylindrical mold as shown in FIG. 8. A blend of CB:AB oligomers (at 50:50 mass ratio) was mixed with milled carbon fiber (Zoltek PX35MF0150) and PTFE at mass proportions of 70:25:5 and thoroughly blended in a laboratory blender. Blended composition was loaded into the mold followed by the mold anvil. Loaded mold was inserted into a vacuum-enclosed hot press. A temperature cycle consisting of a 2° C. / min ramp to 270° C. followed by a 30 minute hold f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com