Compact LNG production train and method

a production train and compact technology, applied in the direction of lighting and heating equipment, industrial buildings, solidification, etc., can solve the problems of large overall footprint of modularized lng production plants, large capital expenditure, and compromises in the placement of module boundaries, so as to achieve the effect of relatively small footprint of each process uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052]Certain terms used herein are defined as follows:

[0053]The term “LNG” refers to liquefied natural gas.

[0054]The term “plant” may refer to the LNG production plant including one or more LNG production trains.

[0055]The term “facility” may typically refer to an LNG production plant, but may alternatively refer to an assembly in general.

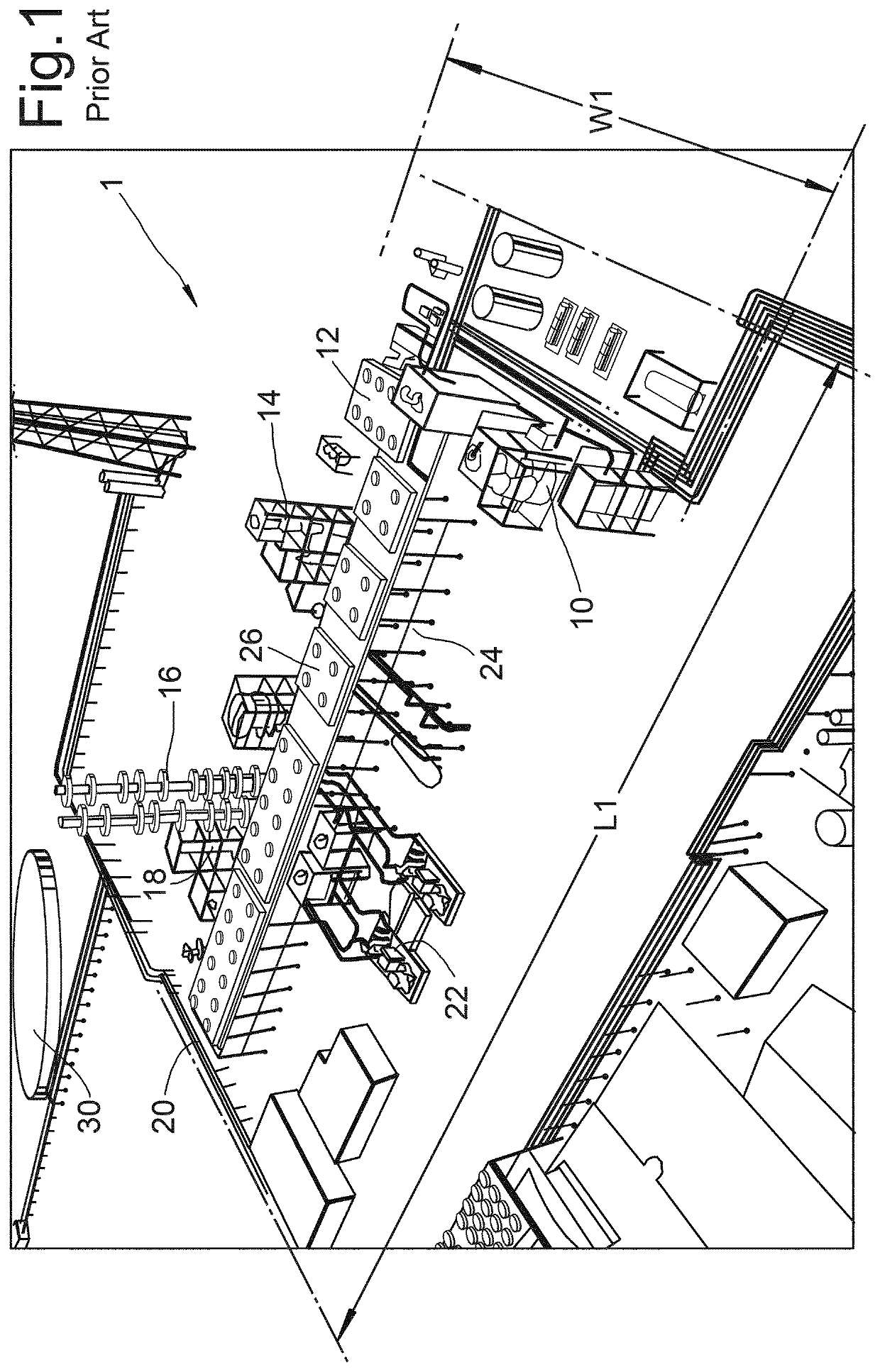

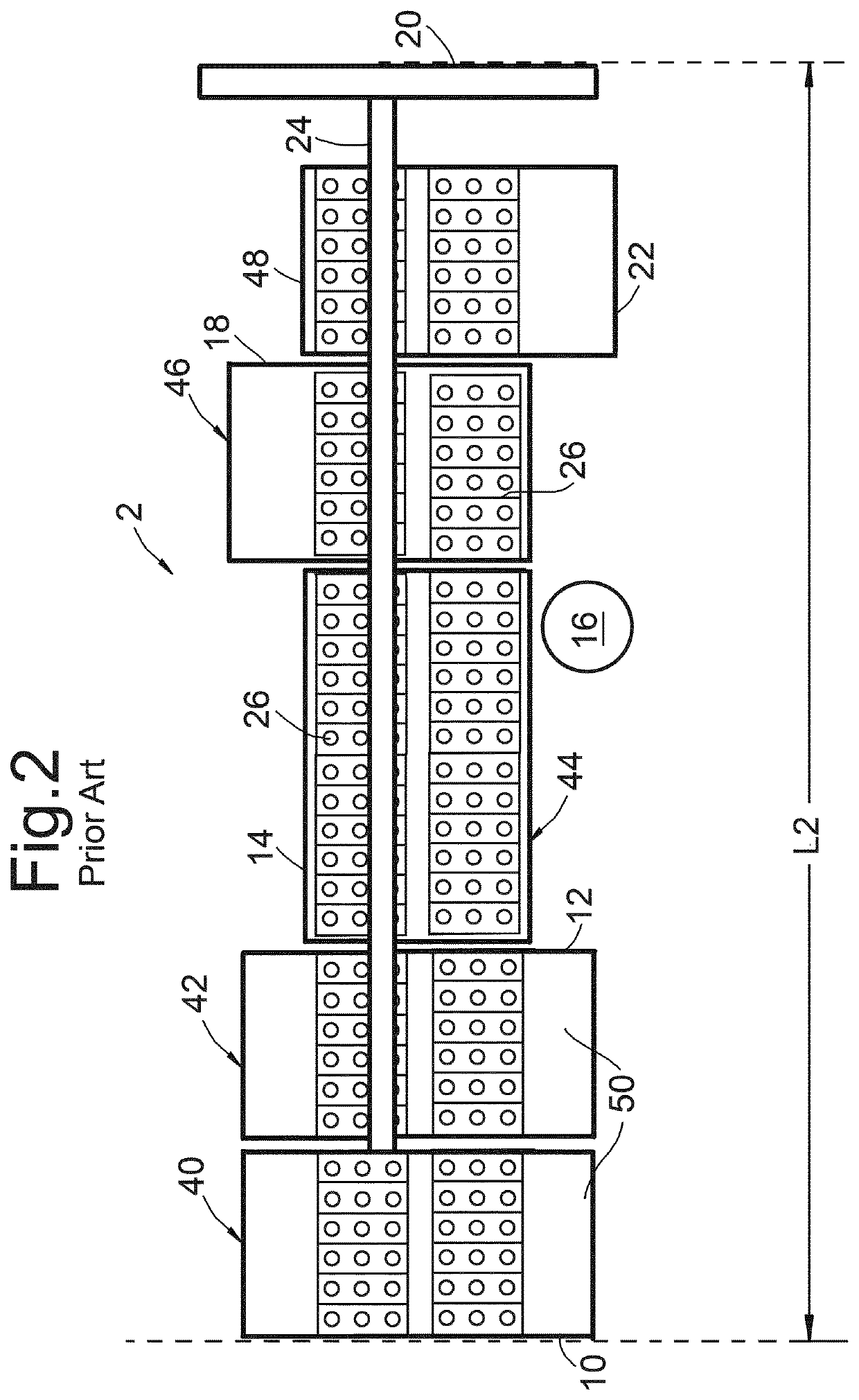

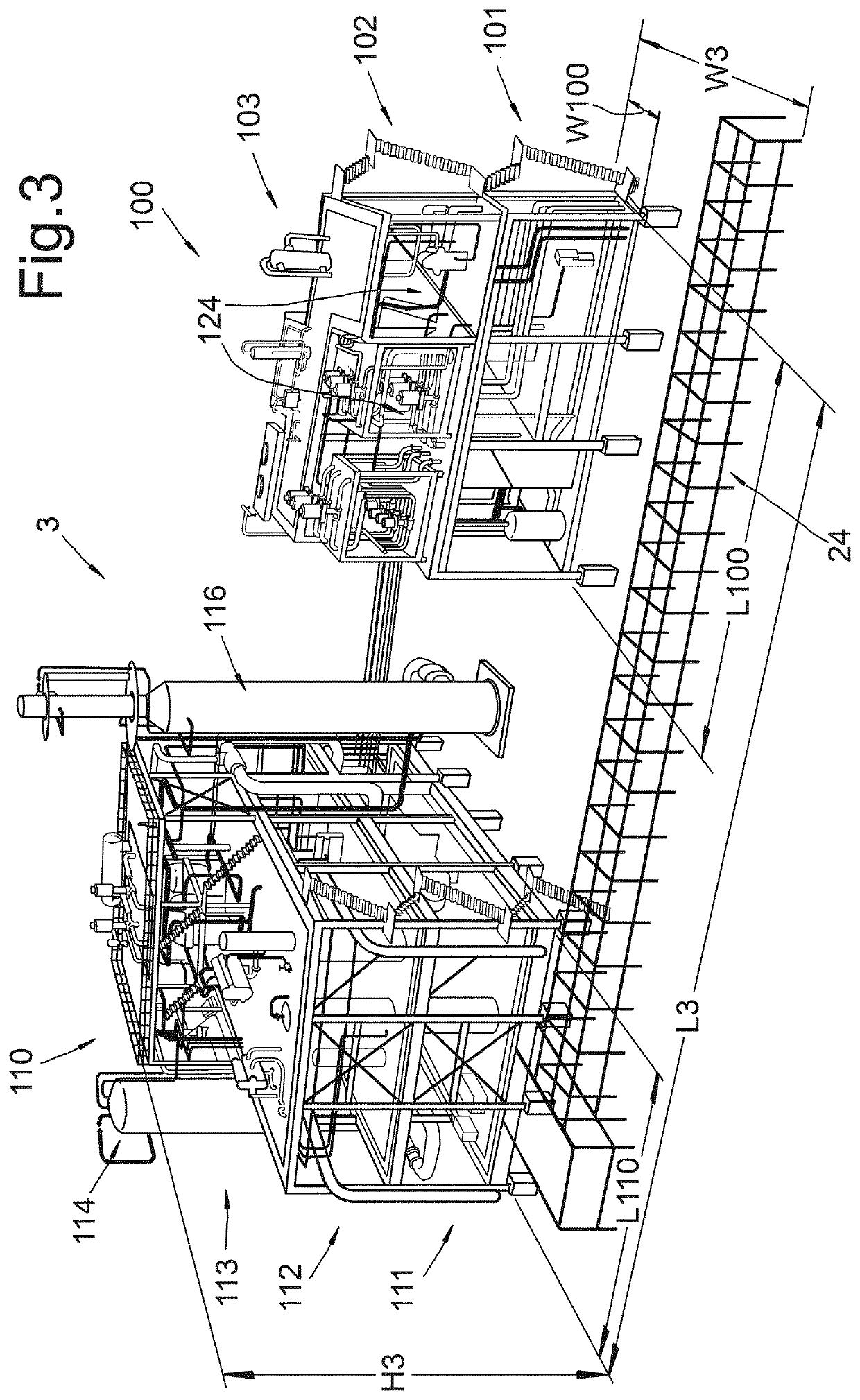

[0056]The term “LNG production train” refers to an assembly comprising process units used for the pre-treatment of a natural gas feed stream to remove contaminants and provided treated gas, and process units used for receiving the treated gas and subjecting the treated gas to cooling to form liquefied natural gas.

[0057]The term “stick-built” refers to an LNG production train which has sections built in subsequent order at the production location. Herein, stick-built is similar to conventional construction. Both refer to construction of a production train or another section of a plant predominantly at a production location. Herein, production locati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com