Hydrophobic NANO silica mixed thermoplastic hot-melt film with excellent adhesive strength

a thermoplastic and nano silica technology, applied in the direction of film/foil adhesives, heat-activated film/foil adhesives, film/foil adhesives without carriers, etc., can solve the problems of reducing or eliminating the sewing process, requiring a lot of manpower during the manufacturing process, and prone to overflow, etc., to improve the tensile strength, improve the dispersibility, and improve the effect of water resistan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0072]TPU hot melt film production method according to aspects of the present invention is a method for producing a mixture by mixing it with a raw material used in the polymerization of TPU pellet, the production method may include the following five steps.

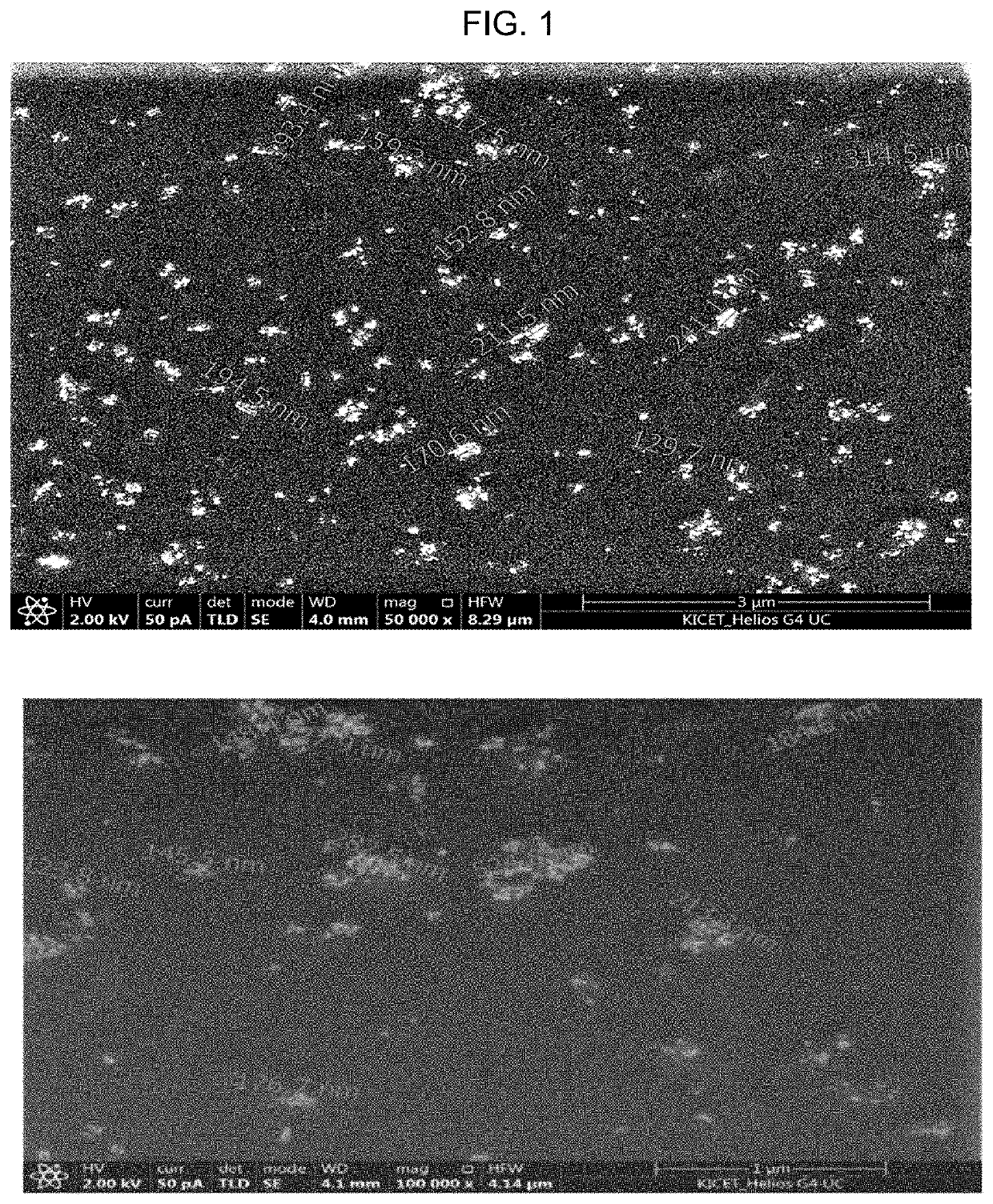

[0073]In the first step, 100 nm or less nanosilica was treated with dimethyl dichlorosilane to prepare hydrophobic nanosilica particles having a primary particle size of about 20 nm and including dimethyl groups as hydrophobic functional groups on the surface.

[0074]The second step is to prepare a raw material for the conventional TPU pellet polymerization, in particular polyol, isocyanate, short chain glycol is prepared.

[0075]In the third step, any one of the raw materials shown in step 2 is selected to add hydrophobic nanosilica, or hydrophobic nanosilica is added to the raw materials and kneaded. At this time, the temperature is 80 to 100° C. and the stirring speed is preferably about 20 to 30 rpm.

[0076]In the fourth step, the ...

example 2

[0078]Next, a method of preparing a hot melt film by preparing a masterbatch using a hydrophobic nanosilica, and mixing the masterbatch into a TPU resin or EVA resin by content according to the present invention will be described in detail.

[0079]First, the resins presented above are weighed by content. At this time, the content of the hydrophobic nanosilica is preferably in consideration of dispersibility such that the maximum does not exceed 40%.

[0080]Next, the hydrophobic nanosilica and the resin was added to a conventional kneader, kneaded at a speed of 20 to 30 rpm at a temperature of 100 to 120° C., and cooled, and pulverized so that the diameter was less than 10 mm, and then put into a conventional twin extruder (not shown). At this time, the temperature of the twin screw extruder is maintained at a temperature of 150 to 200° C.

[0081]When the compounded resin in the twin screw extruder is made into pellets while being poured into a cooling water at a temperature of 15 to 20° C...

experimental example 1

[0084]In order to demonstrate the effect on the hydrophobic nanosilica mixed TPU hot melt film prepared in example 1 will be described in detail the experimental results for the adhesion test.

[0085]Below, engineered and sandwich meshes mainly used for an upper and lining fabrics mainly used for lining are used.

[0086]In addition, the adhesive structure and the press working conditions are for the engineered mesh or sandwich mesh corresponding to the upper, an outer material, and the TPU hot melt film is inserted between the lining fabric corresponding to the lining.

[0087]And then press work was carried out at 60 kgf pressure for 30 seconds at 130° C., TPU hot melt film was used as a conventional TPU hot melt film and a TPU hot melt film mixed by the hydrophobic nanosilica content, respectively.

[0088]Table 2 below shows an adhesion test data by thickness / hydrophobic nanosilica content of TPU hot melt film, and the part “-” without numerical value in the adhesive strength (kgf / cm2) fie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com