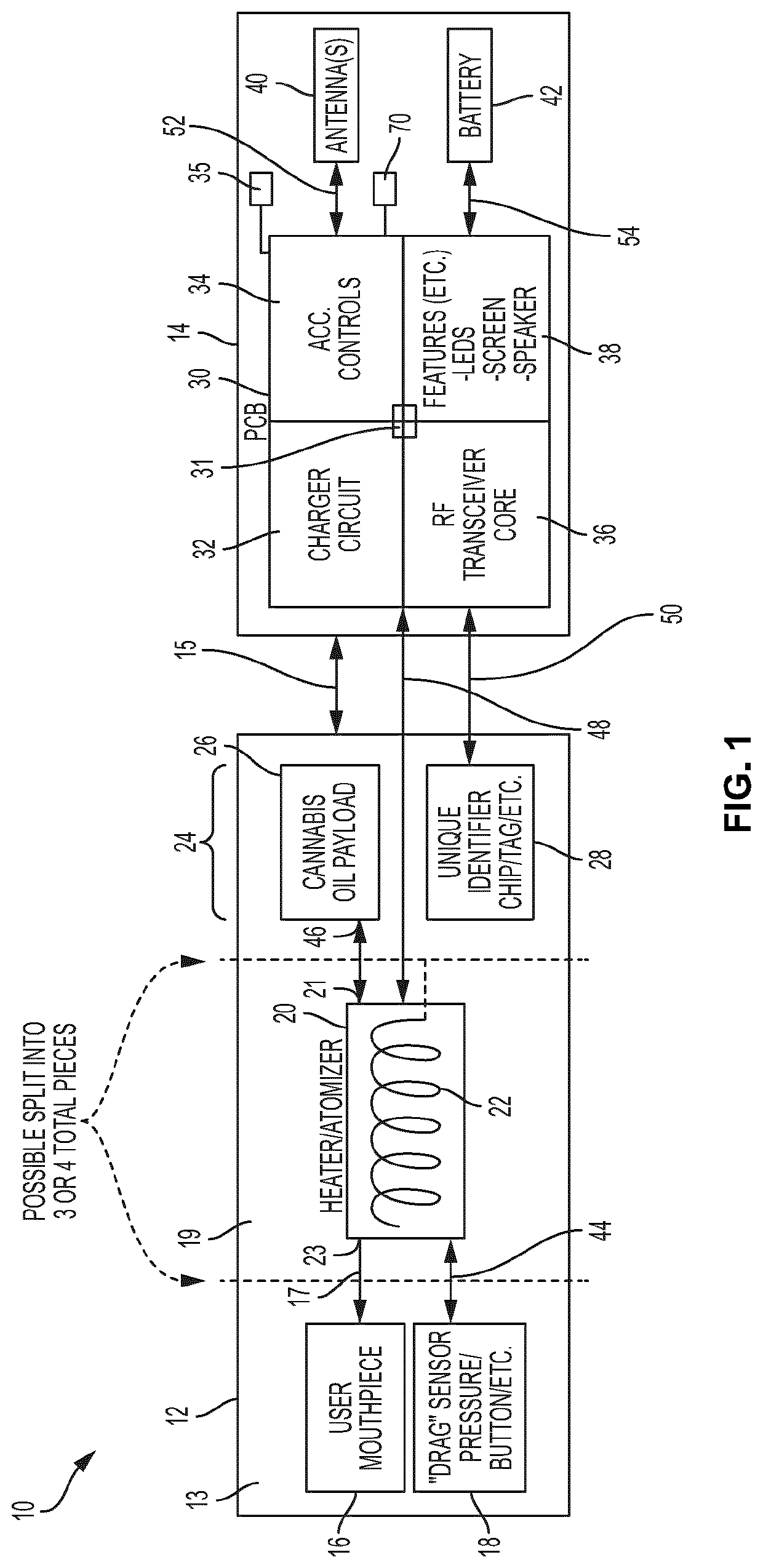

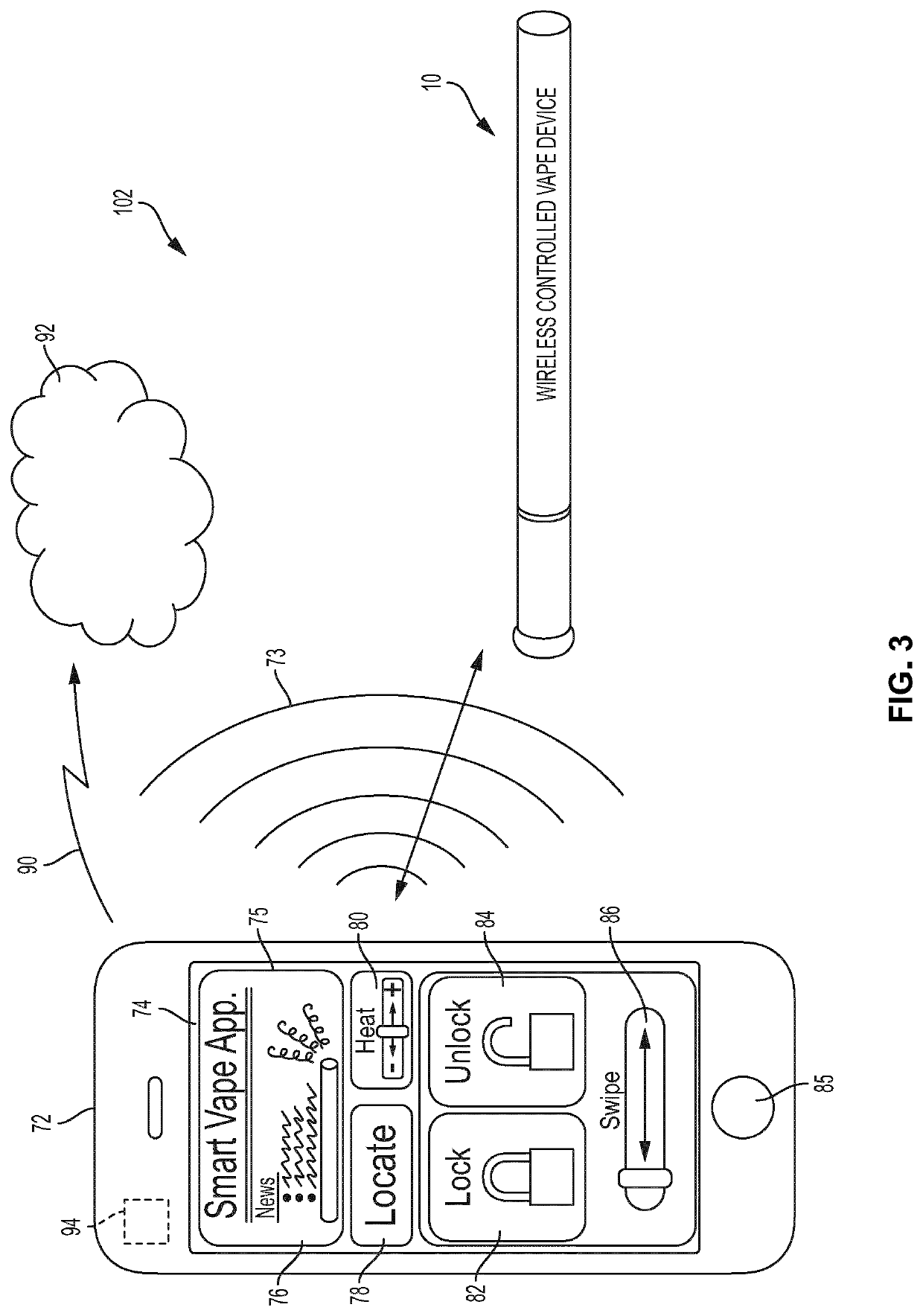

Vape devices, including cartridges, tablets, sensors, and controls for vape devices, and methods for making and using the same

a technology of vape devices and control devices, which is applied in the direction of tobacco and other directions, can solve the problems of no control, no control, no control to prevent the use of the vape device by anyone other than the user of the vape device, etc., and achieve the effect of reducing the amount of payload, and improving the flow of payload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

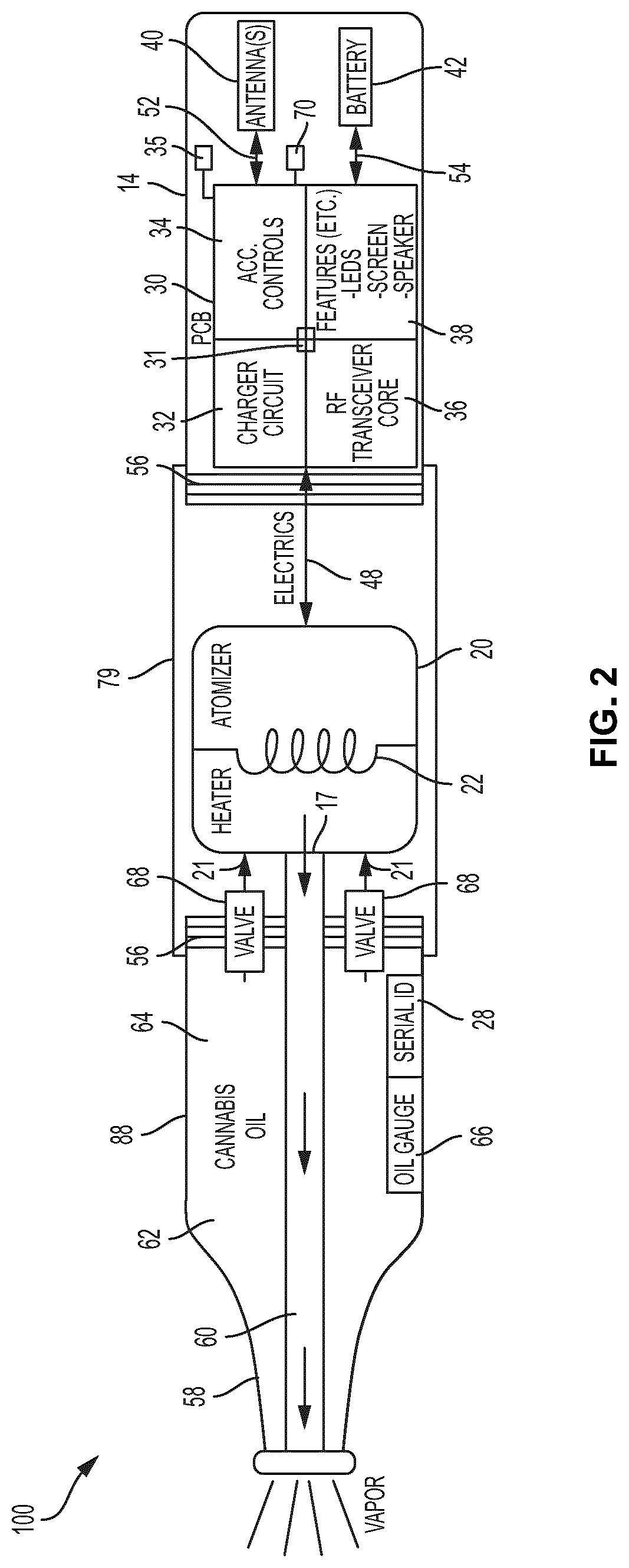

second embodiment

of Vape Device

[0169]Referring to FIG. 2, another embodiment of vape device 100 is shown. In some embodiments, vape device 100 can comprise control assembly 14, atomizer assembly 79 and mouthpiece assembly 88 operatively coupled together in that order using mechanical connection means 56 to join the subassemblies together. Mechanical connection means 56 can comprise one or more of threaded connection means, magnetic connection means and friction or press-fit connection means, and any of the connection means 15 described above, including 510 threaded connectors. In some embodiments, mouthpiece assembly 88 can comprise a mouthpiece 58 in communication with the outlet of atomizer 20 via conduit 60. Mouthpiece assembly 88 can further comprise a payload reservoir 62 that can be filled with a payload 64 that may be liquid or oil. The payload 64 can flow from payload reservoir 62 to inlet 21 of atomizer 20 via one or more valves 68. In some embodiments, mouthpiece assembly 88 can comprise I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com