Functional yeast protein concentrate

a technology of protein concentrate and yeast, which is applied in the field of functional yeast protein concentrate, can solve the problems of consuming about one-third of the world's total land area for livestock feed, posing a huge problem to the food and agricultural industry, and affecting the health of the environmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

on Method Using Carbon Filtration

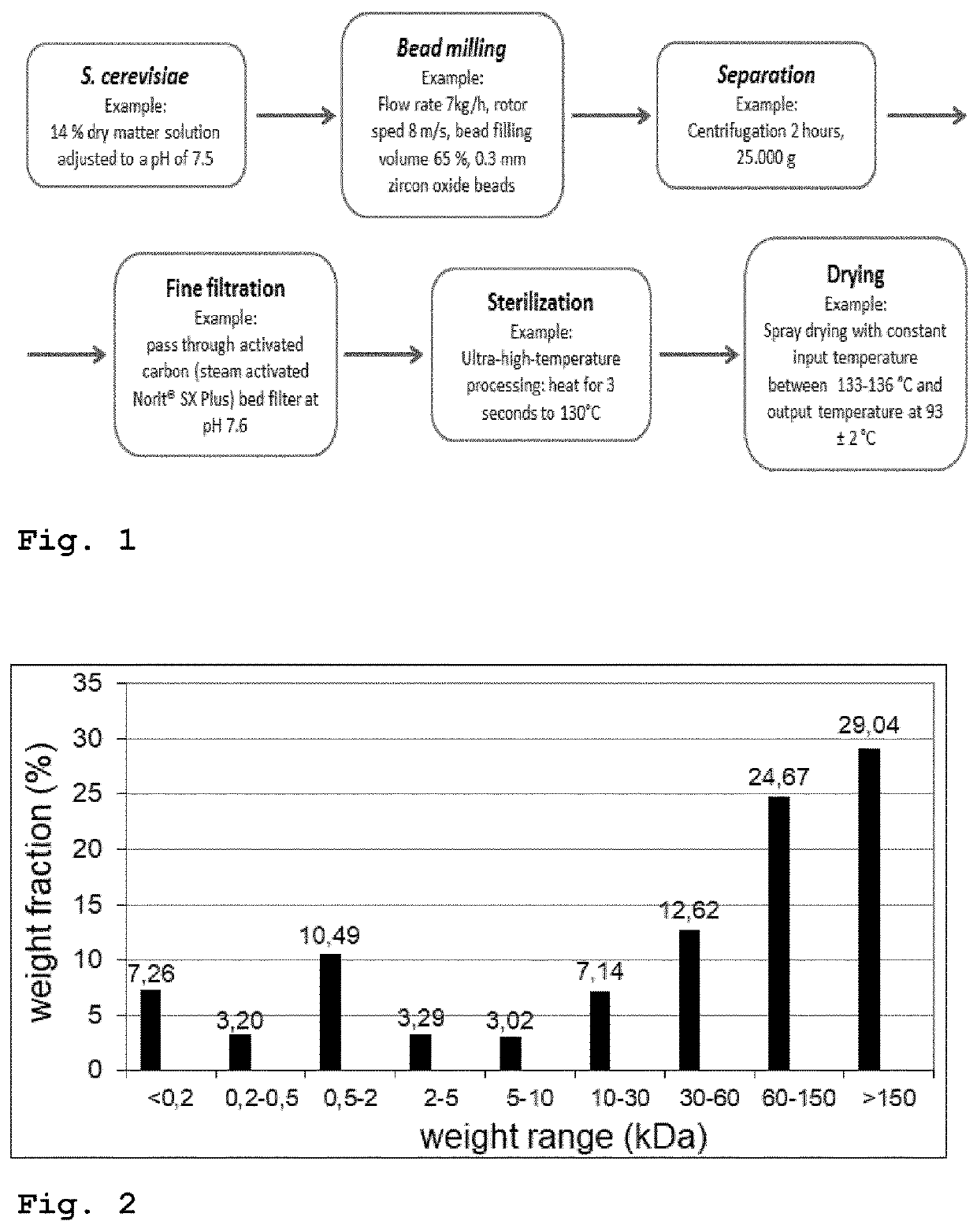

[0086]Saccharomyces cerevisiae A2W5 yeast cells were harvested from a yeast cell culture and suspended in water. The dry matter content was adjusted to 14%. The suspension had a volume of 1 L. The pH of the suspension was adjusted to pH 7.5 using NaOH.

[0087]Cell rupture was performed in a Dyno®-Mill Multi Lab Wab from Willy A. Bachofen AG (Muttenz, Switzerland) using yttria-stabilized zirconium oxide beads with a size of 0.25-0.35 mm. The flow rate was set to 7 kg / h and the rotor speed to 8 m / s. The bead filling volume was set to 65%.

[0088]The efficiency of cell rupture was confirmed by measuring the protein extraction yield using the method of Kjeldahl, J. Fresenius, Zeitschrift f. anal. Chemie (1883) 22:366.

[0089]The pH of the lysate obtained from the bead mill was adjusted to 7.6 using NaOH. Subsequently, the lysate was subjected to centrifugation for 120 minutes at 25000×g in a Heraeus Multifuge X3R. The supernatant was separated from the sedimen...

example 2

on Method Using Ultrafiltration

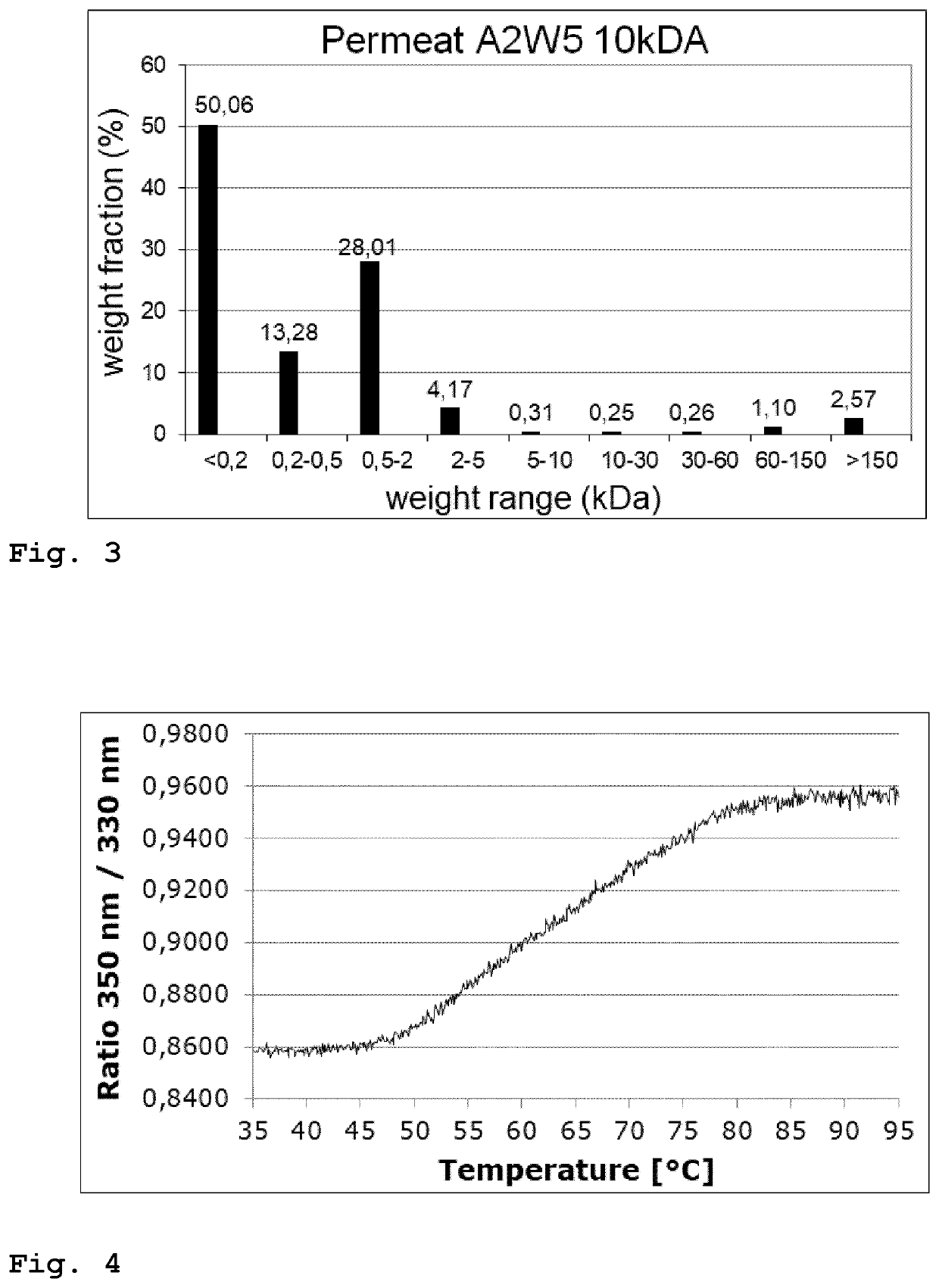

[0093]The experiment described in Example 1 was repeated with the exception that an ultrafiltration was used instead of activated carbon filtration. Ultrafiltration was done with a polyethersulfone (PES) UF GR 81PP membrane having a MWCO of 10 kDa. Seven support plates were equipped with a stop disk such that 14 filters were used in total. The filter setup was washed according to the manufacturer's instructions. In the beginning the retentate flow rate was 2.3 L / min and the permeate flow rate was 0.064 L / min. After 20 min, the retentate flowed with 2.2 L / min, while the permeate flowed out with 0.054 L / min. The permeate was analyzed using Size Exclusion Chromatography (SEC). The results are shown in FIG. 3. It can be seen that only particles that were smaller than the cutoff of the membrane were able to pass. This indicates that the yeast proteins remained in the retentate and there was no significant protein loss. The solution obtained from ultrafiltra...

example 3

on of a Protein Gel

[0094]The powders obtained in Examples 1 and 2 were tested for their gelling properties upon reconstitution in water. For this purpose, the protein powder was dissolved in tap water to give a 20% (w / w) solution.

[0095]Next, the melting temperature range of the proteins in the protein concentrate was measured between room temperature and 95° C. using a Tycho NT.6 (NanoTemper Technologies GmbH, Munich). FIG. 4 shows that the proteins inside the invented product mainly melt between 45° C. and 83° C. The protein gel was assessed by a sensory panel of at least 7 people for gel firmness and flavour profile. There was a general agreement within the panel regarding the main perception of the samples. The taste was described as salty, sweet and roasted. There was no strong yeast flavour noted by the panel. At the same time, the gel was found to be firm and resembled cooked egg white in terms of its consistency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com