Electric powertrain cooling assembly and cooling assembly operating method

a technology of electric powertrain and cooling assembly, which is applied in the direction of climate sustainability, propulsion parts, vehicle sub-unit features, etc., can solve the problems of reducing fuel cell operating efficiency, presenting packaging challenges, and prone to degradation of the cooling system of the mckibben, so as to reduce the modularity of the vehicle, reduce the operating efficiency of the fuel cell, and efficiently install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

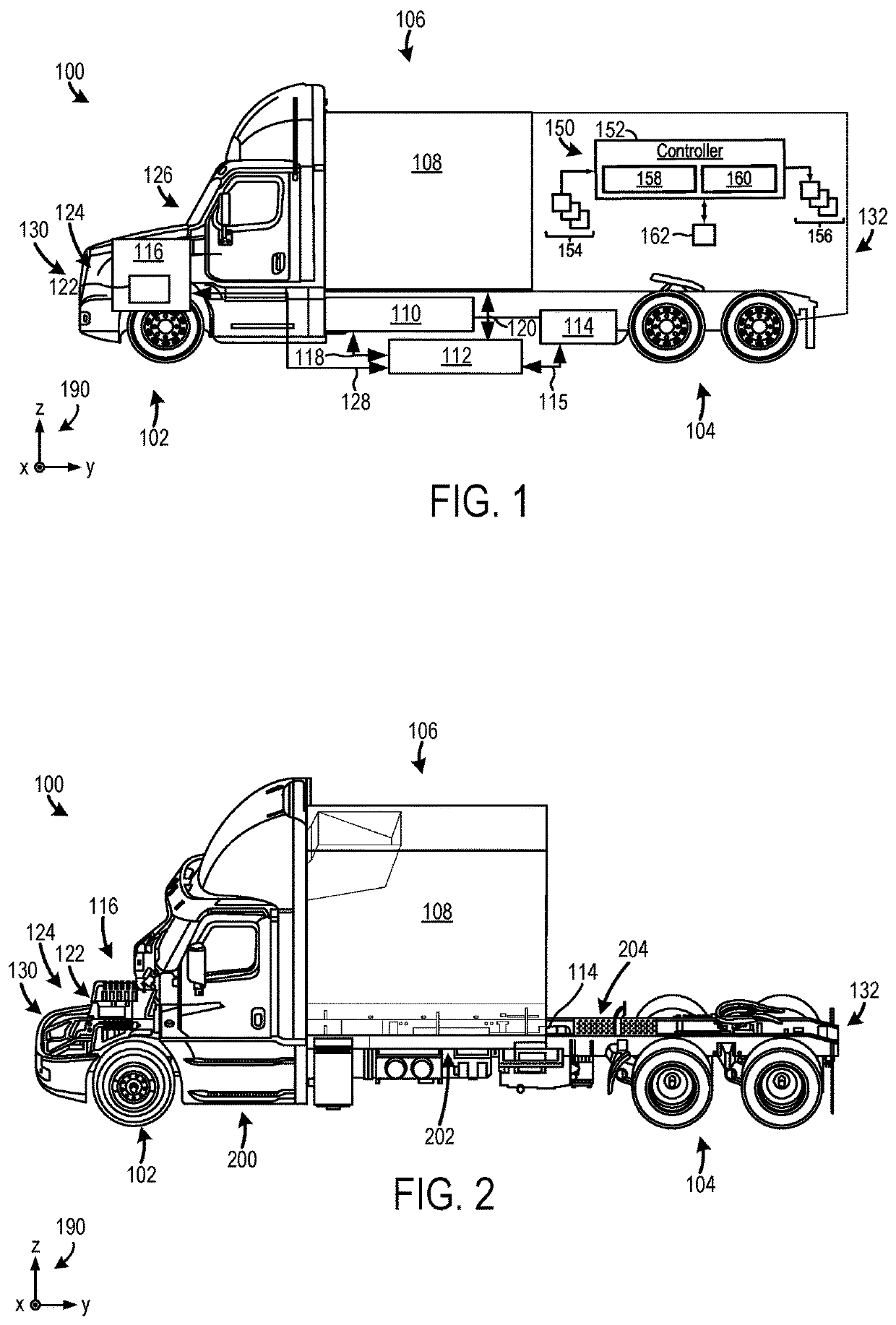

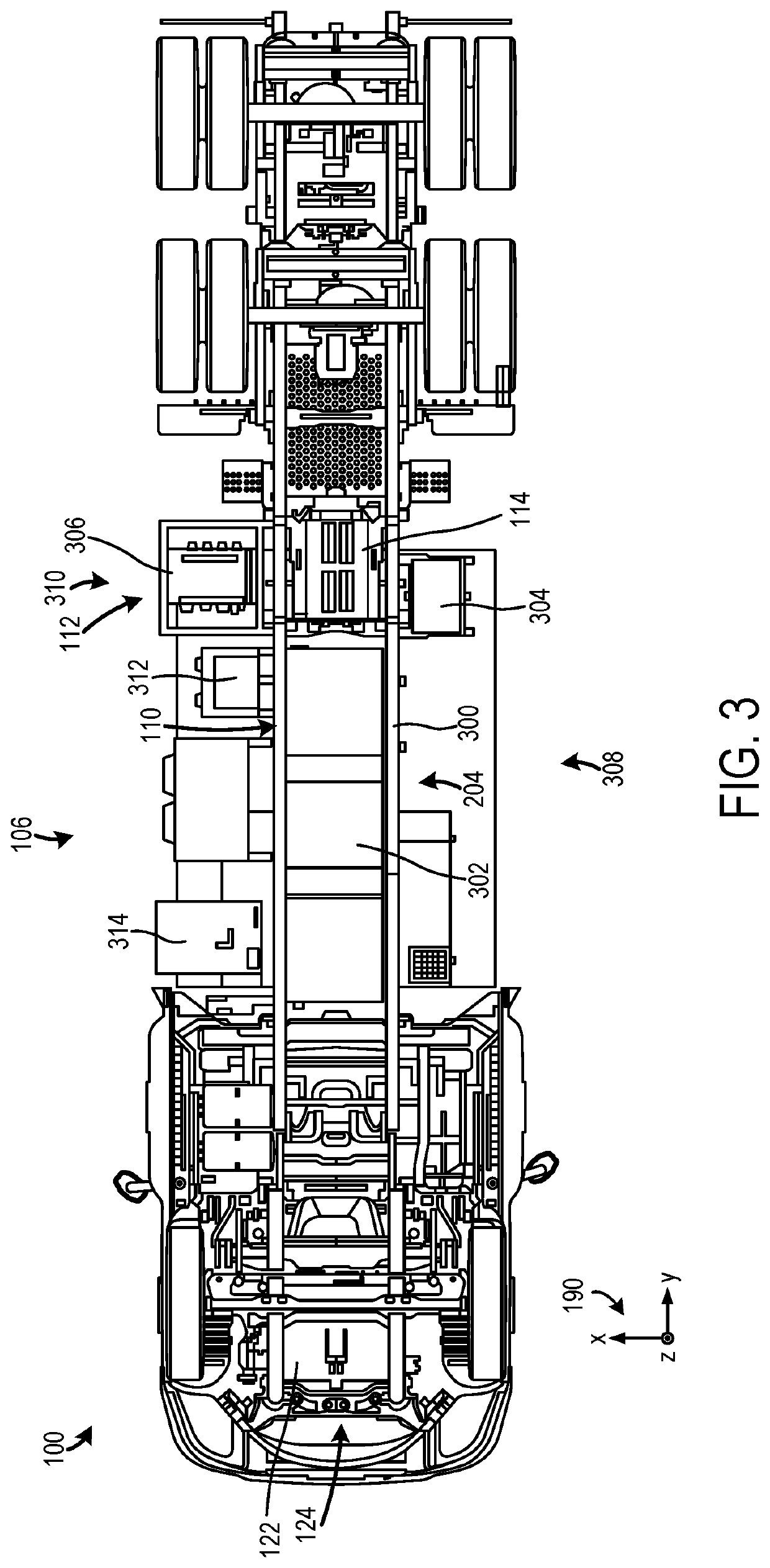

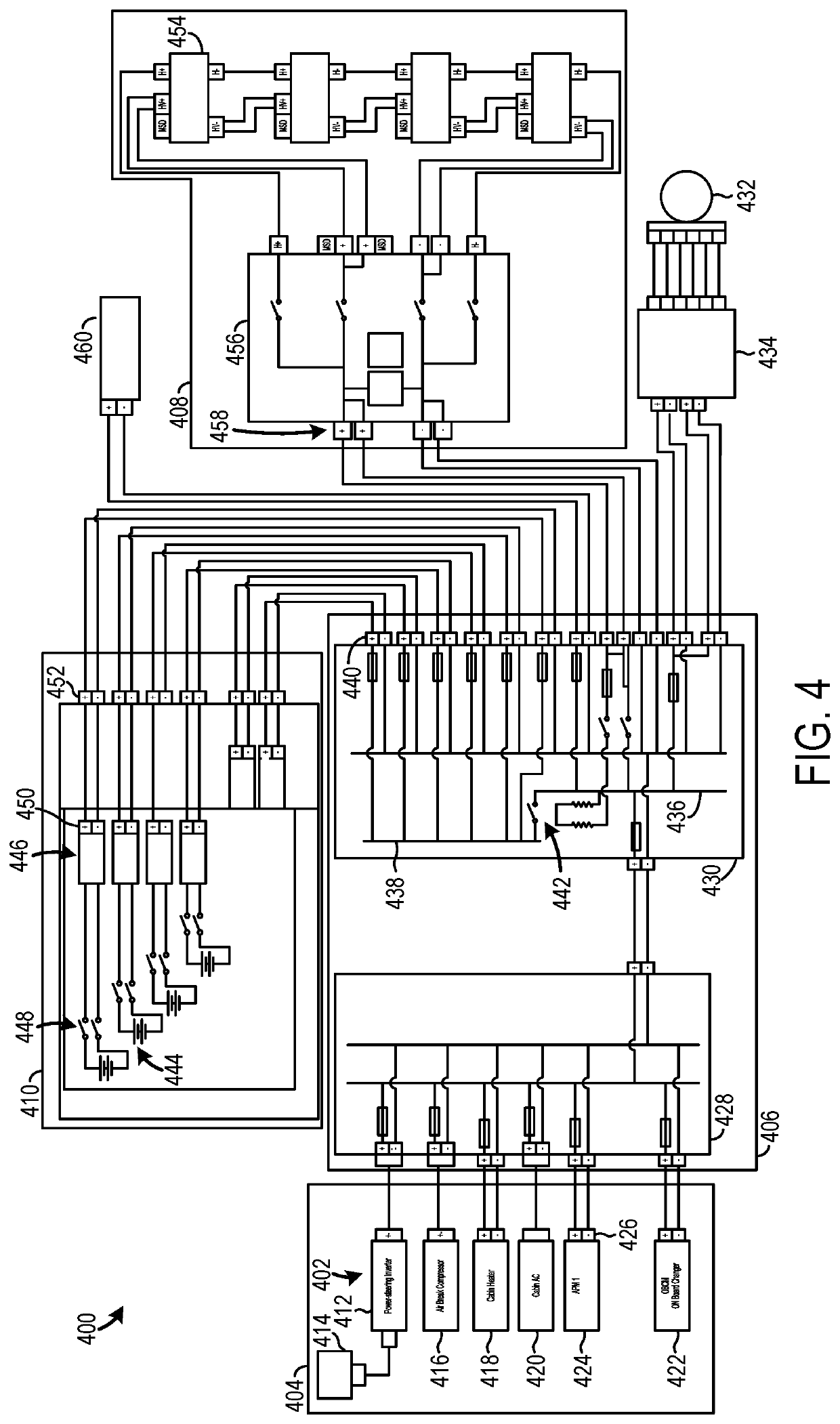

[0019]A fuel cell cooling arrangement and associated systems that achieve a higher level of cooling and efficiency in comparison to previous cooling systems are described herein. To achieve the high level of heat rejection and efficiency, the fuel cell cooling arrangement is positioned above a hydrogen fuel cell assembly that is positioned behind a vehicle cab. This fuel cell cooling arrangement includes an inlet manifold positioned vertically above the cab and in fluidic communication with a fan array that is designed to drive airflow to a fuel cell assembly heat exchanger. The cooling arrangement further includes a deflector with inlets that are designed to guide ram air, generated during vehicle travel, to the fan arrays. To form inlets, the deflector may include slats that extend across a front opening. The attack angle of the slats may be selected to strike a desired balance between airflow through the fuel cell cooling system and vehicle drag. Positioning the cooling component...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| gross vehicle weight rating | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com