Methods using a peroxide-generating compound to remove group VIII metal-containing residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

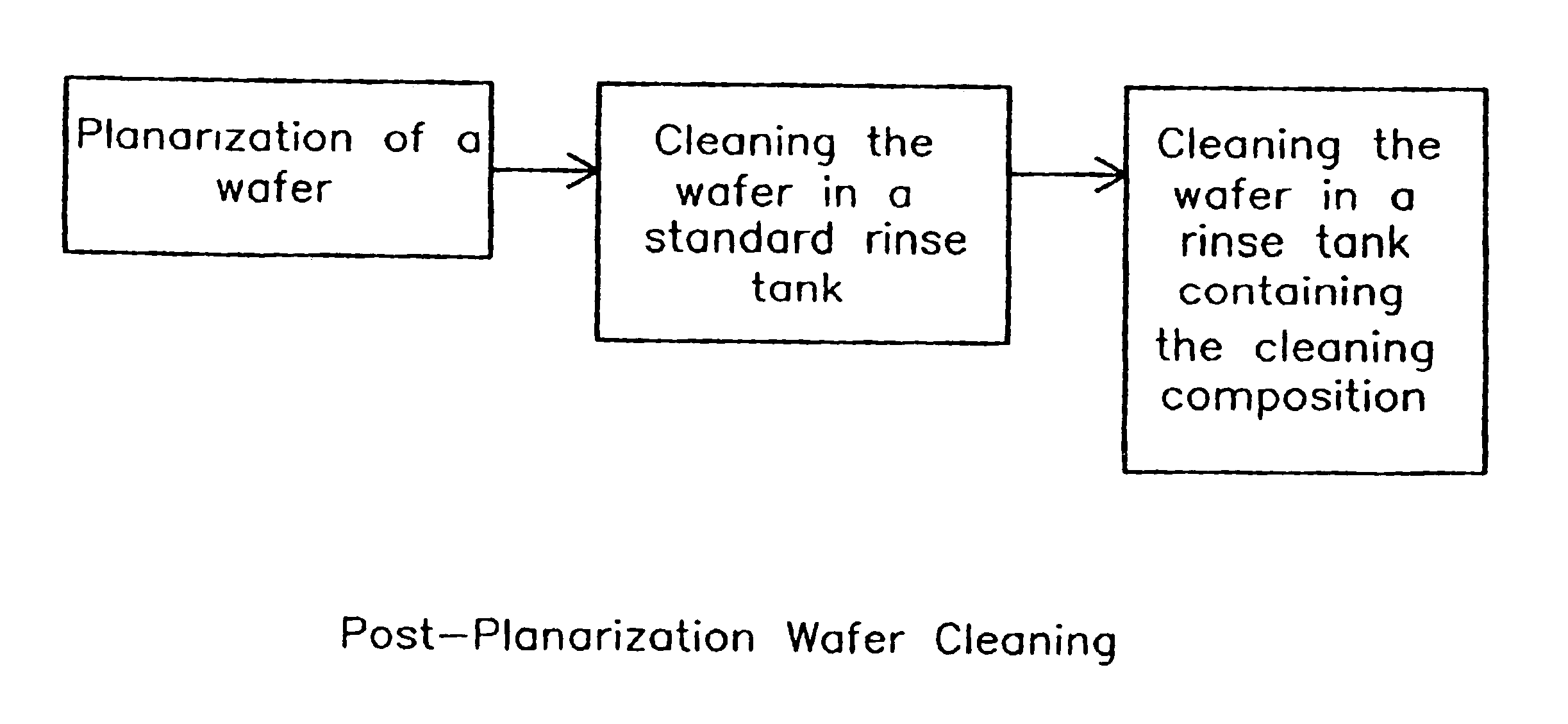

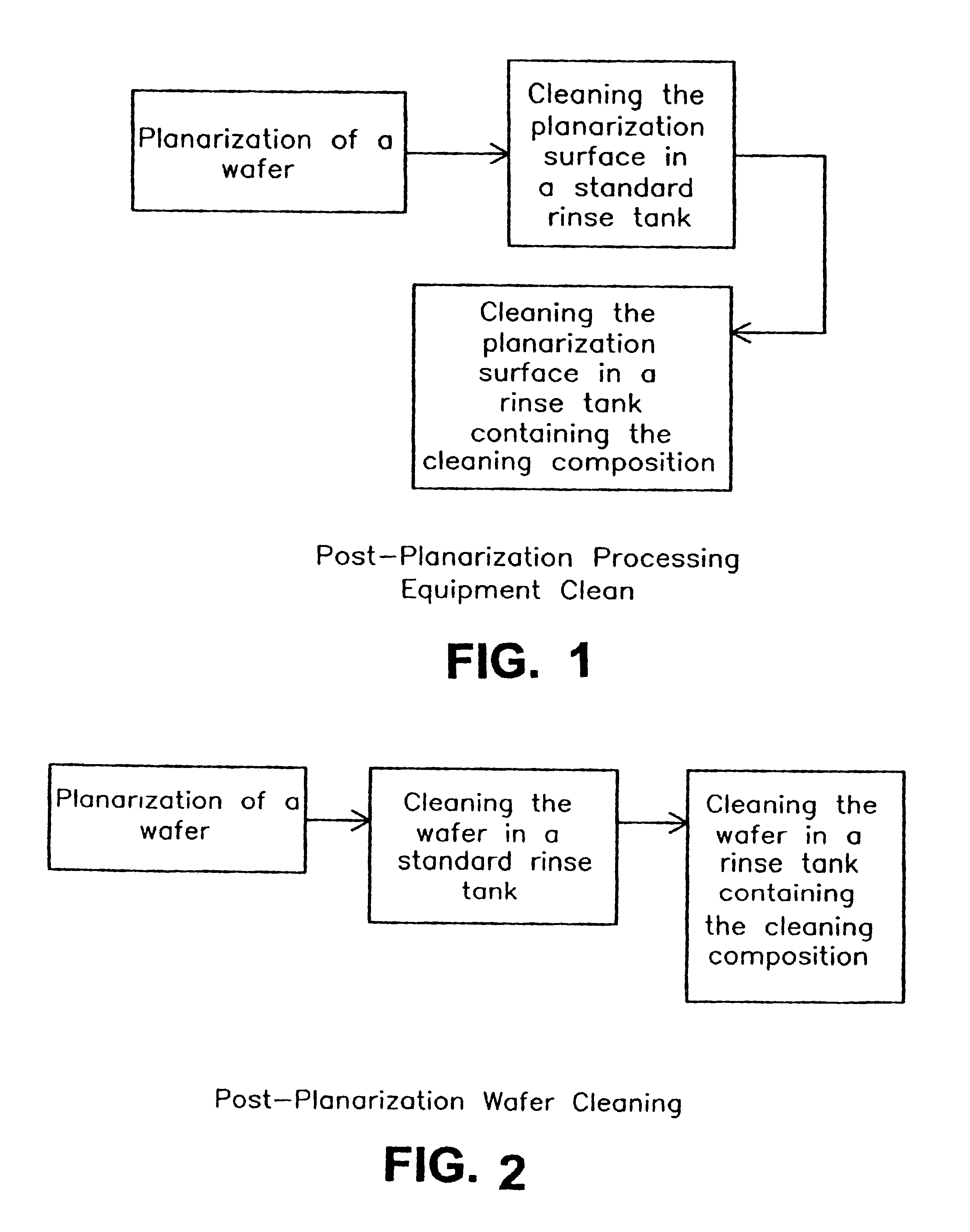

Method used

Image

Examples

example

[0038]A semiconductor wafer is processed using a polishing tool thereby producing a platinum film on the surface of the wafer. This is immersed in a bath containing a solution of deionized water, ammonium citrate, and hydrogen peroxide in a volume ratio of 10 to 1 to 0.5 and at a temperature of 40° C. Megasonics is applied to suspend the slurry particles and the platinum residue in solution. The wafer is then transferred to a vessel for rinsing and then drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com