Herbal essential oil emulsion covered by utilization of core-shell technology, and preparation method thereof

A kind of herbal essential oil and technology, which is applied in the direction of biocide-containing paints, coatings, antifouling/underwater coatings, etc., can solve the problems of affecting the specific function of the coating, failing to achieve the expected effect, and poor water resistance, etc., to achieve Improved air quality, uniform distribution, and excellent film comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

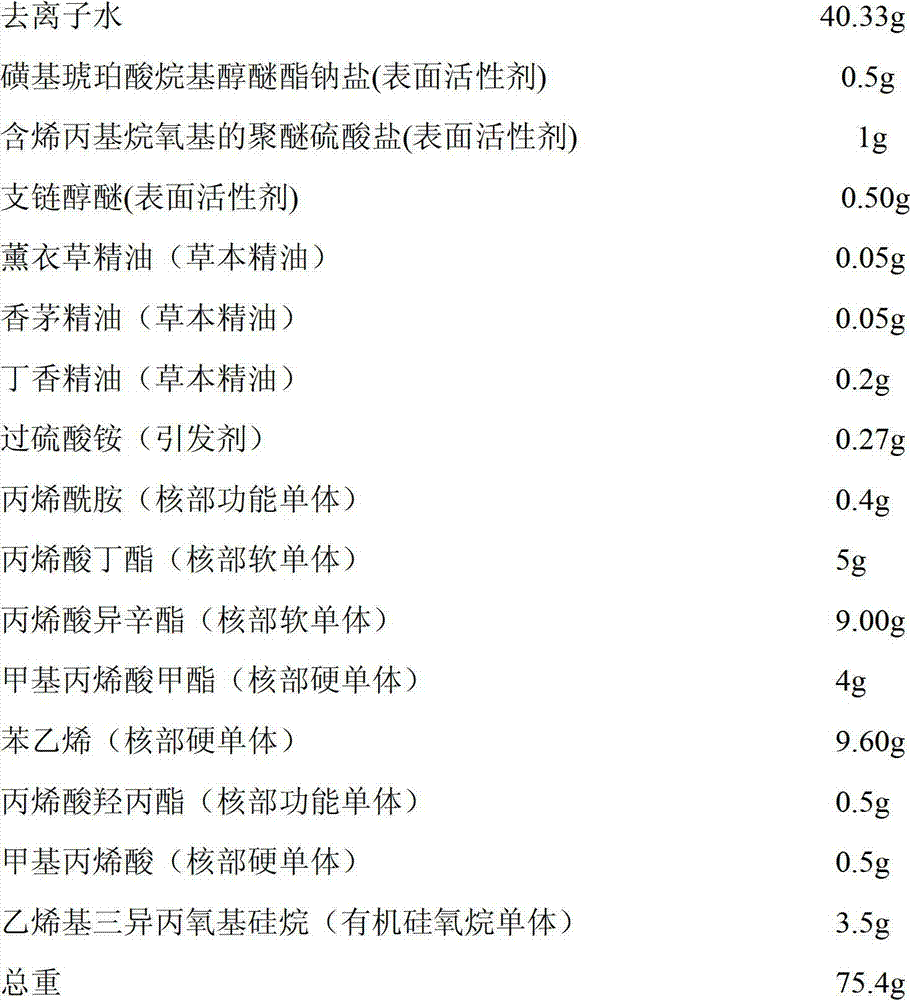

[0066] a. Nuclear raw materials:

[0067]

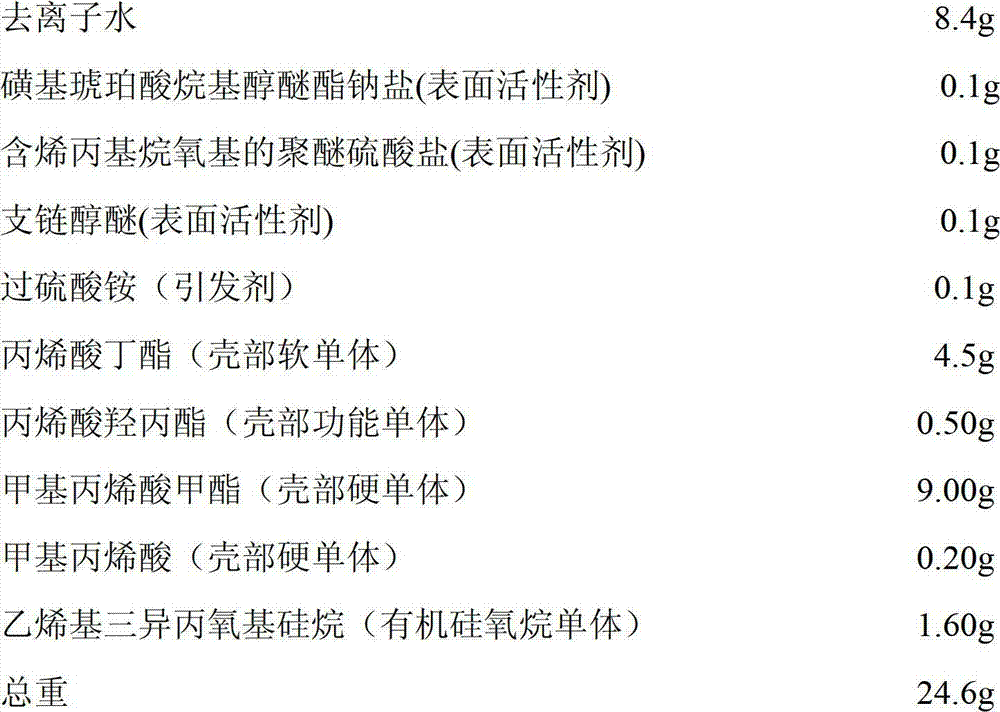

[0068] b. Shell material:

[0069]

[0070] 2 / 3 of deionized water, 1 / 3 of surfactant, 1 / 3 of initiator, 1 / 4 of core soft monomer, 1 / 6 of core hard monomer, and 1 / 6 of core hard monomer Add functional monomer 1 / 4 and organosiloxane monomer 1 / 6 to the reaction kettle, raise the temperature to 80-85°C under stirring conditions, and react after 10-15 minutes of stabilization, form seed nanocrystal emulsion, and then add group a dropwise Divide the pre-emulsion composed of the remaining part; the dropping time is 3 hours, the reaction temperature is 80-87°C, after the dropping, graft polymerization is initiated and kept for 1 hour, and the formed emulsion particles are the core layer. Then continue to drop the pre-emulsion prepared after mixing component b, the dropping time is 1.5-2 hours, the reaction temperature is 80-87 ° C, to form shell particles, and after the drop is completed, graft copolymerization is initiated and kept...

Embodiment 2

[0072] a. Nuclear raw materials:

[0073]

[0074]

[0075] b. Shell material:

[0076]

[0077] 2 / 3 of deionized water, 1 / 3 of surfactant, 1 / 3 of initiator, 1 / 4 of core soft monomer, 1 / 6 of core hard monomer, and 1 / 6 of core hard monomer Add functional monomer 1 / 4 and organosiloxane monomer 1 / 6 to the reaction kettle, raise the temperature to 80-85°C under stirring conditions, and react after 10-15 minutes of stabilization, form seed nanocrystal emulsion, and then add group a dropwise Divide the pre-emulsion composed of the remaining part; the dropping time is 3 hours, the reaction temperature is 80-87°C, after the dropping, graft polymerization is initiated and kept for 1 hour, and the formed emulsion particles are the core layer. Then continue to drop the pre-emulsion prepared after mixing component b, the dropping time is 1.5-2 hours, the reaction temperature is 80-87 ° C, to form shell particles, and after the drop is completed, graft copolymerization is initia...

Embodiment 3

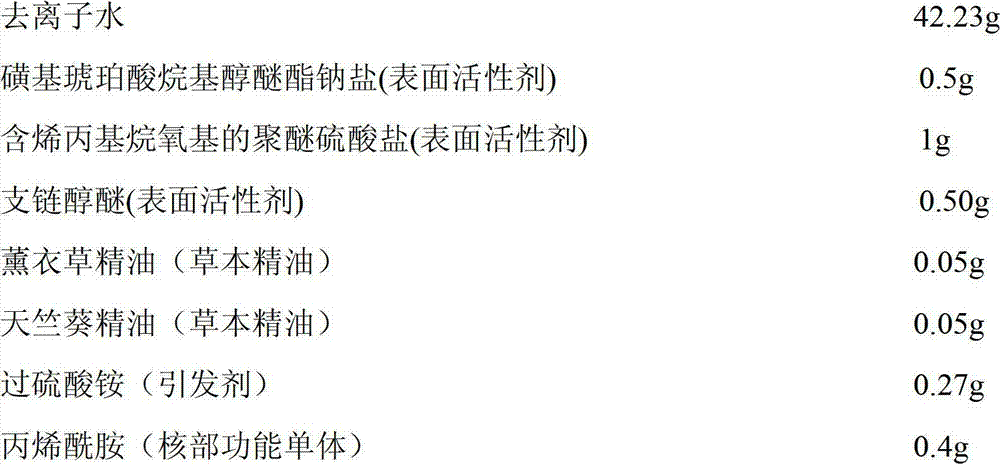

[0079] a. Nuclear raw materials:

[0080]

[0081] b. Shell material:

[0082]

[0083]

[0084] 2 / 3 of deionized water, 1 / 3 of surfactant, 1 / 3 of initiator, 1 / 4 of core soft monomer, 1 / 6 of core hard monomer, and 1 / 6 of core hard monomer Add functional monomer 1 / 4 and organosiloxane monomer 1 / 6 to the reaction kettle, raise the temperature to 80-85°C under stirring conditions, and react after 10-15 minutes of stabilization, form seed nanocrystal emulsion, and then add group a dropwise Divide the pre-emulsion composed of the remaining part; the dropping time is 3 hours, the reaction temperature is 80-87°C, after the dropping, graft polymerization is initiated and kept for 1 hour, and the formed emulsion particles are the core layer. Then continue to drop the pre-emulsion prepared after mixing component b, the dropping time is 1.5-2 hours, the reaction temperature is 80-87 ° C, to form shell particles, and after the drop is completed, graft copolymerization is initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com