Thermal barrier coating material, gas turbine parts and gas turbine

a technology of thermal barrier coating and gas turbine, which is applied in the direction of surface reaction electrolytic coating, liquid fuel engine components, non-positive displacement fluid engines, etc., can solve the problems of insufficient crystalline stability, insufficient durability, and insufficient crystalline stability, so as to achieve high thermal cycle durability, reduce the effect of thermal cycle stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

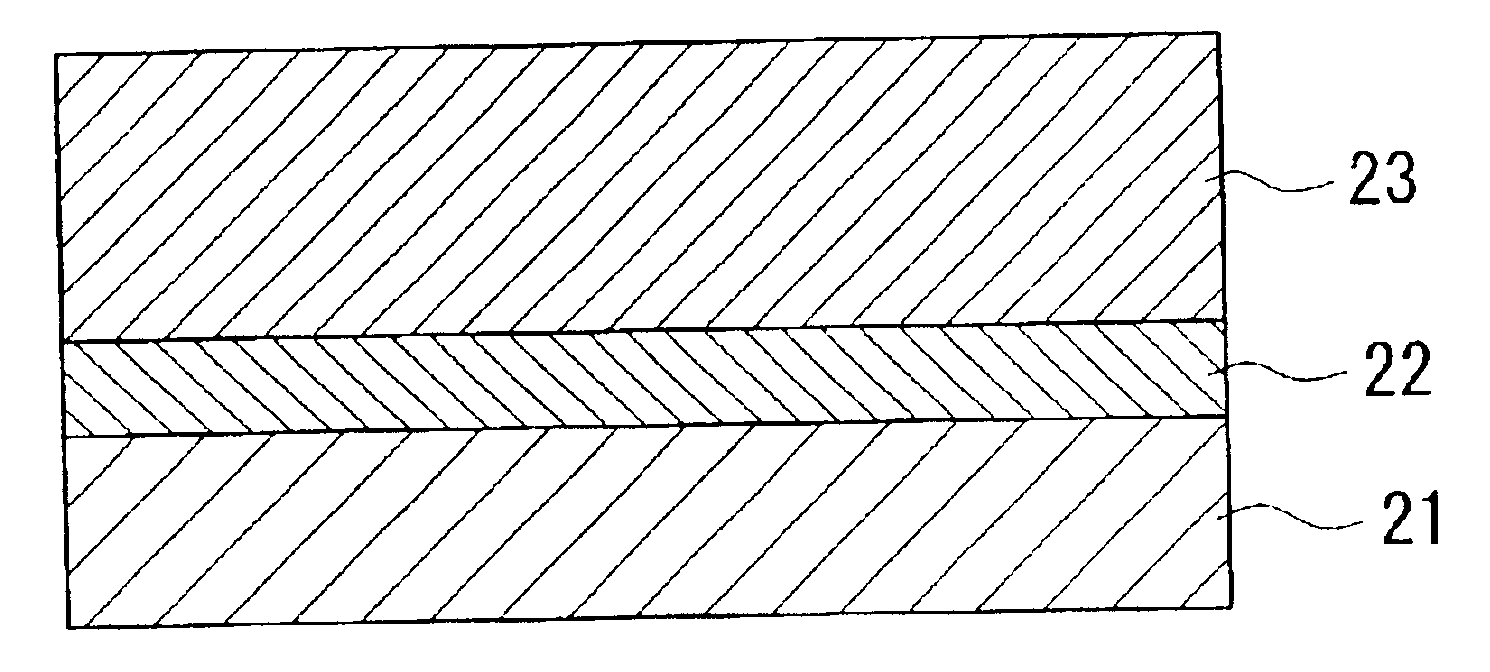

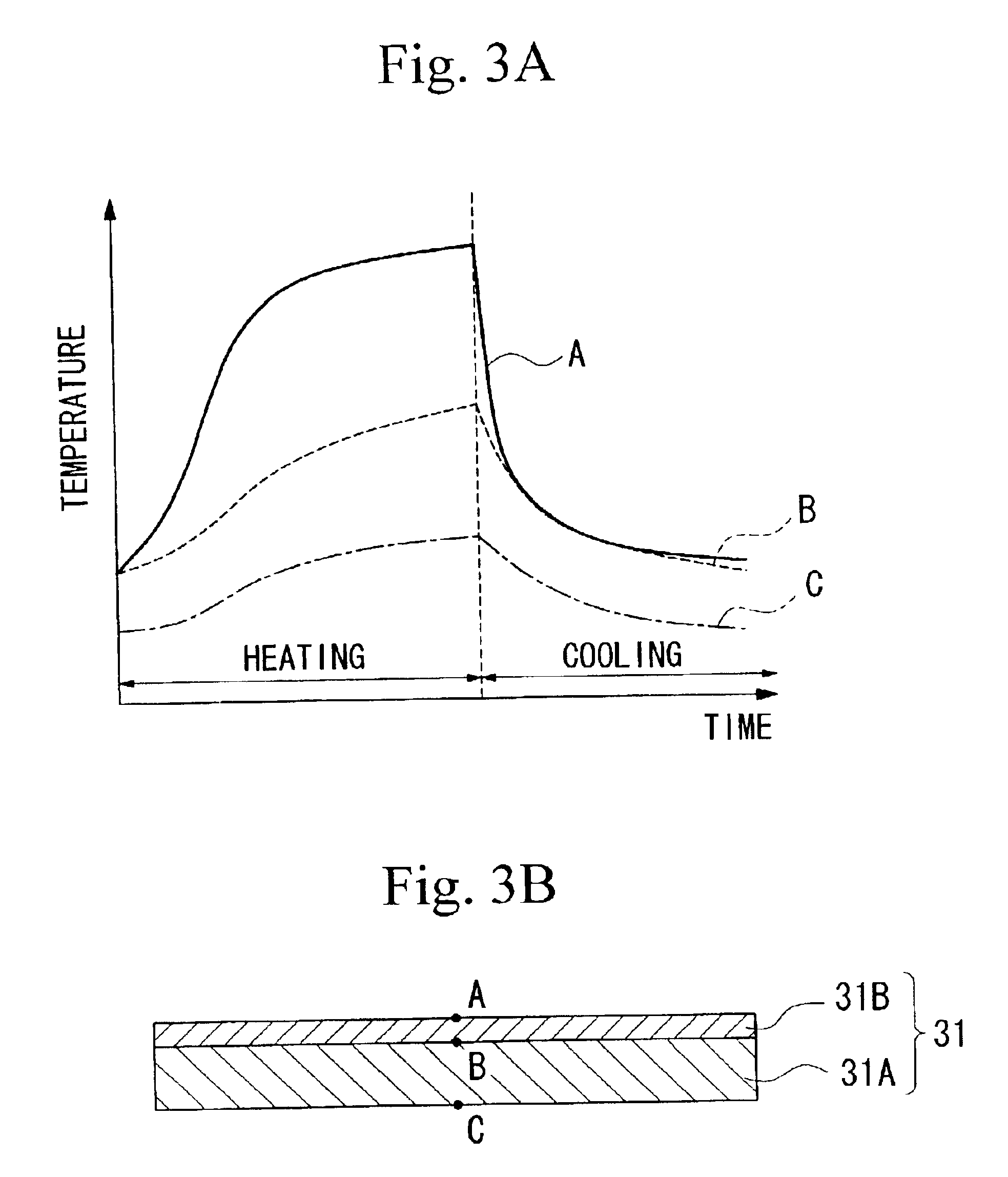

[0043]In this example, samples having ErSZ layers formed from ZrO2 with varying Er2O3 content were fabricated and tested to measure the thermal cycle life, in order to determine the change in the thermal cycle life with the changing quantity of Er2O3 content. Ni-based heat-resistant alloy with the composition of Ni—16Cr—8.5Co—1.7Mo—2.6W—1.7T—0.9Nb—3.4Al—3.4Ti was used for the base of the samples. After sand-blasting the base surface with Al2O3 particles, the surface was coated with a CoNiCrAlY alloy that has a composition of Co—32Ni—21Cr—8Al—0.5Y by a low-pressure plasma thermal spray process so as to form a bonding coat layer. Then a ceramic layer (ErSZ layer) was formed by an atmospheric plasma thermal spray process on the bonding coat layer made of the CoNiCrAlY alloy, thereby forming the thermal barrier coating material. The Er2O3 content in the ceramic layers of different samples (samples Nos. 1 to 12) are shown in Table 1.

[0044]The bonding coat layer (CoNiCrAlY) was formed to ...

example 2

[0052]Next, in order to study the change in durability with different void ratios in the ceramic layer made of ErSZ, samples were made by forming thermal barrier coating material films, having the ceramic layers of different void ratios shown in Table 2, on bases. Void ratios in the ceramic layers of these samples were set to predetermined values by controlling the thermal spray flow and distance. Samples Nos. 15 to 23 were made same manner as in Example 1, except for controlling the void ratio and setting the Er2O3 content to 18% by weight.

[0053]As shown in Table 2, samples Nos. 18 to 20 having void ratios of the ceramic layer within a range from 8% to 15% proved to have higher thermal cycle durability than the thermal barrier coating material film having the ceramic layer made of YSZ of the prior art shown in Table 1.

[0054]

TABLE 2Er2O3 contentVoid ratio afterSample No.(Wt %)thermal sprayingThermal cycle life1518 2%51618 4%151718 6%1501818 8%894191812%>3000201815%1576211820%1652218...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| inlet temperature | aaaaa | aaaaa |

| surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com