Magnetic sensor having a closed magnetic path formed by soft magnetic films

a magnetic sensor and closed magnetic path technology, applied in the field of high sensitivity magnetic sensors, to achieve the effect of high sn ratio of detection output and substantial double thickness of soft magnetic films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

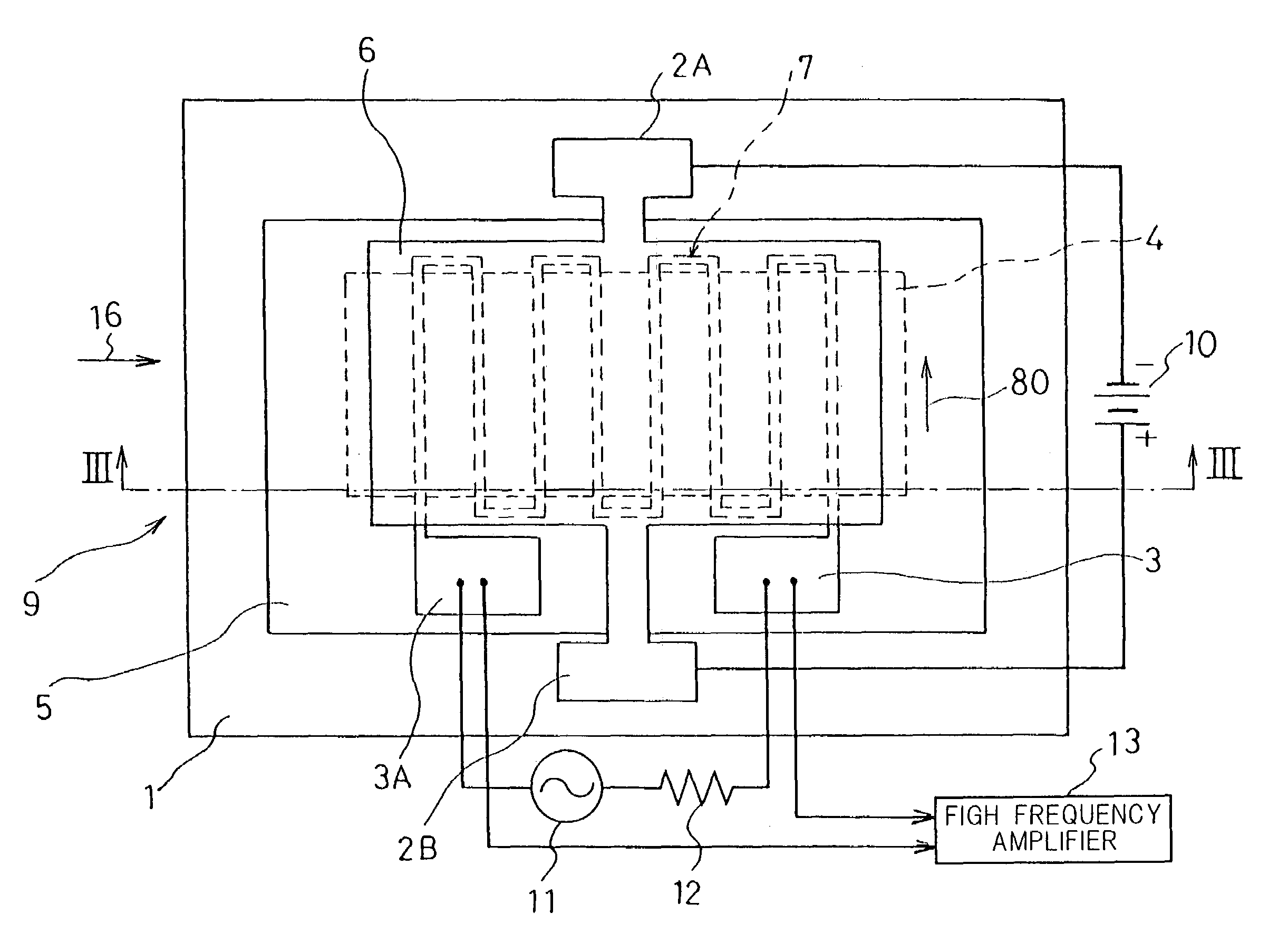

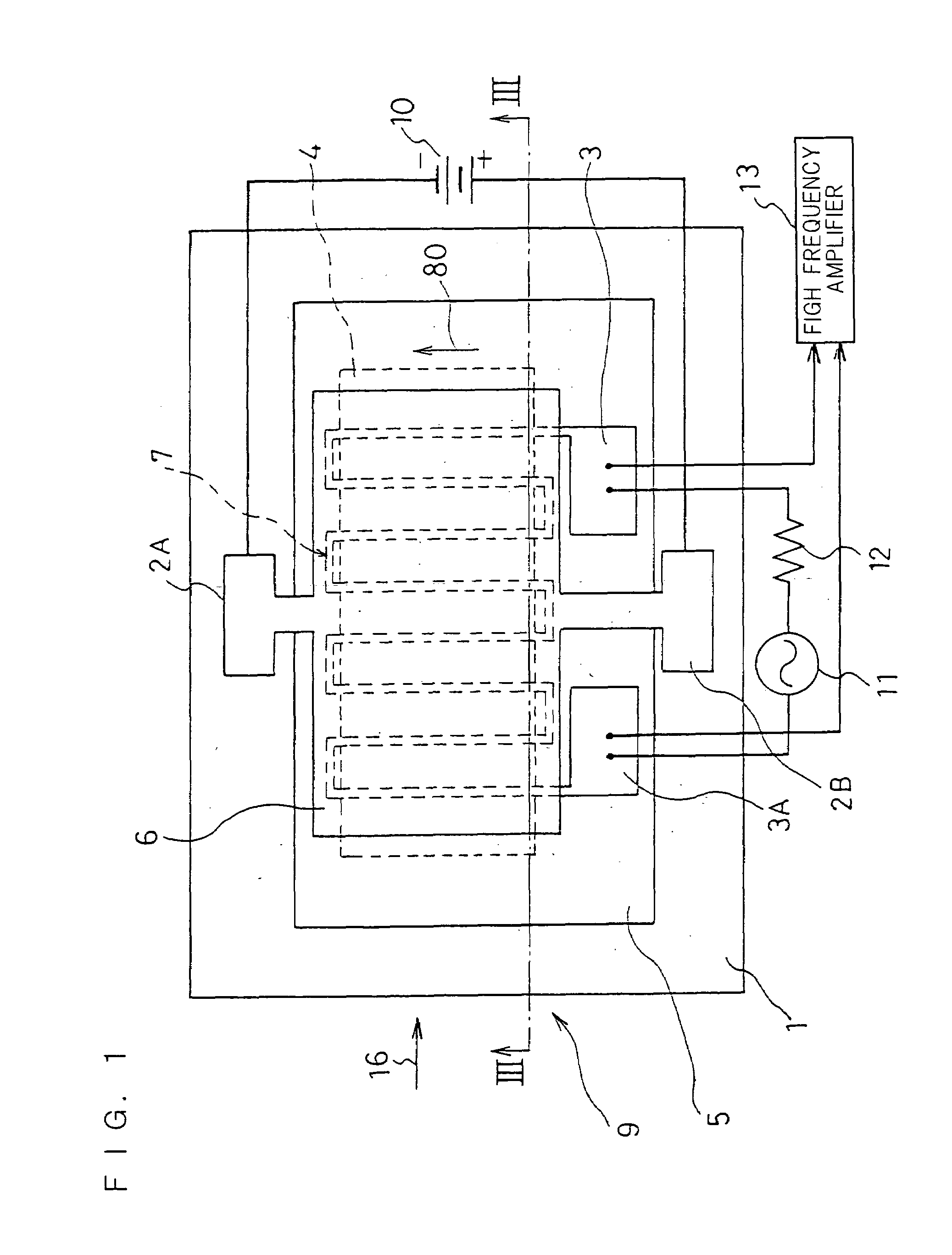

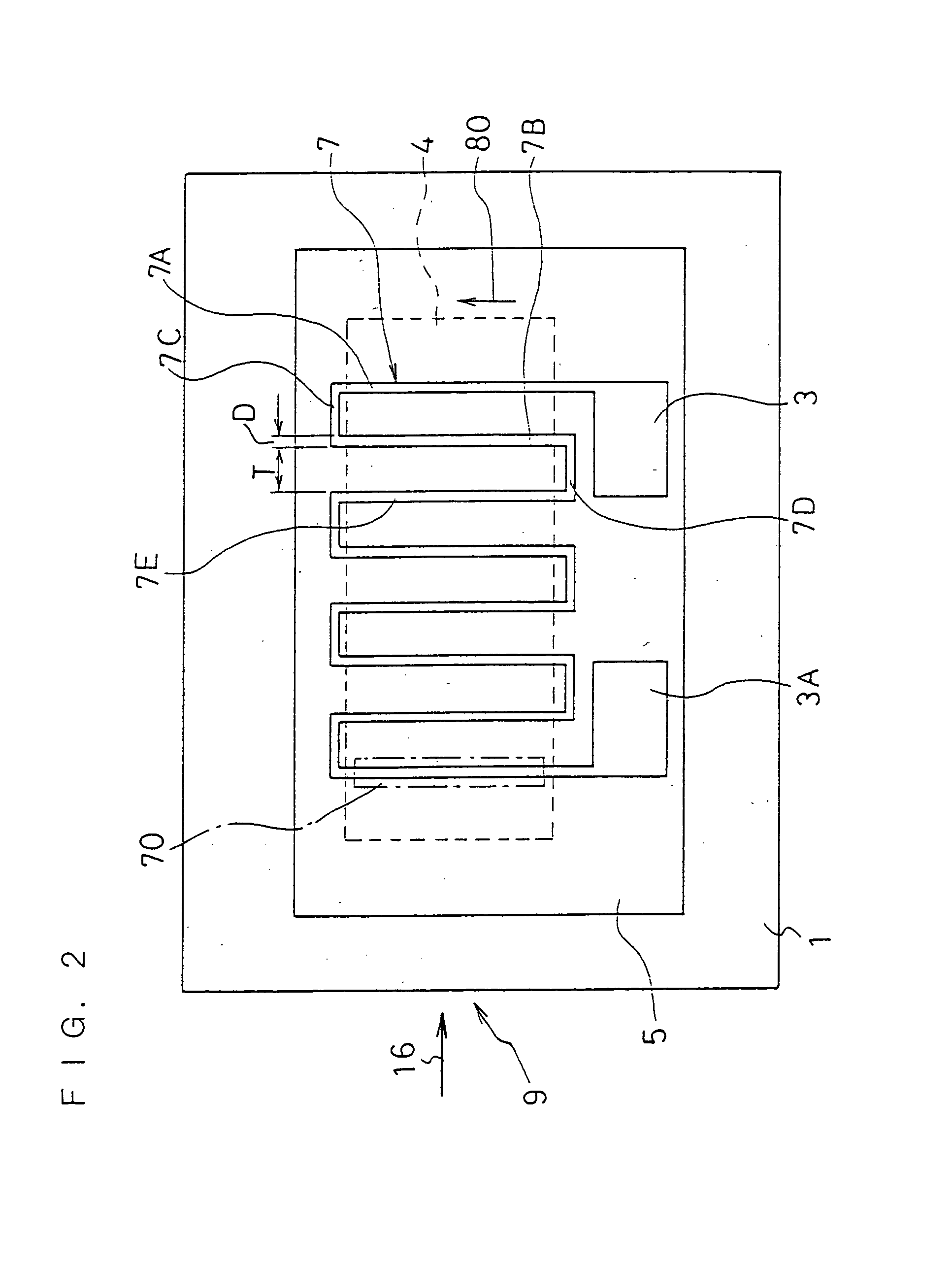

[0074]Description is made as to a magnetic sensor 9 of a first embodiment in the present invention with reference to FIG. 1 to FIG. 7.

[0075]FIG. 1 is a plane view of the magnetic sensor 9 of the first embodiment in the present invention. FIG. 2 shows a plane view in a situation in which a conductive film 6 of copper (Cu) for applying a direct current bias magnetic field in FIG. 1 is removed in order to facilitate the understanding of inside structure. In order to avoid complication of the figures and to facilitate understanding, in all plane views including FIG. 1 and FIG. 2, depressions and projections existing on the surfaces are omitted from illustration. Part (a) of FIG. 3 is a cross-sectional view taken along the line III—III in FIG. 1, and part (b) of FIG. 3 is an enlarged fragmentary cross-sectional view of part (a) of FIG. 3. In cross-sectional views, in order to avoid complication of figures, cross-sections are not hatched.

[0076]In FIG. 1, FIG. 2, part (a) of FIG. 3 and par...

second embodiment

[0083]A magnetic sensor of the second embodiment in the present invention is described with reference to FIG. 8 to FIG. 12.

[0084]In the case that the frequency of the high frequency carrier signal applied to the magnetic sensor utilizing the magnetoimpedance effect is relatively low, in which carrier frequency is from 10 MHz to 20 MHz, the impedance of the conductive nonmagnetic film 7 of the above-mentioned magnetic sensor 9 in FIG. 1 is given principally by the product of the above-mentioned frequency and inductance of the conductive nonmagnetic film 7. Accordingly, in the present embodiment, the demagnetization field of the soft magnetic film 4 of the above-mentioned first embodiment is reduced, thereby to increase the inductance of the conductive nonmagnetic film 7, such that the impedance changes become large even with a weak magnetic field such as geomagnetism.

[0085]FIG. 8 is a plan view of a magnetic sensor of the second embodiment. Referring to the figure, a plurality of nar...

third embodiment

[0090]A magnetic sensor 9C of the third embodiment in the present invention is described with reference to FIG. 13 to FIG. 15.

[0091]FIG. 13 is a plan view of the magnetic sensor9C of the third embodiment in the present invention, and part (a) and part (b) of FIG. 14 are cross-sectional views taken along the line XIV—XIV in FIG. 13. In part (a) of FIG. 14 and part (b) of FIG. 14 of an enlarged fragmentary cross-sectional view, a film 18 including Cobalt (Co) and Platinum (Pt) (hereinafter is referred to as Co—Pt film) is formed on a nonmagnetic substrate 1 of Ni—Ti—Mg. The film 18 is magnetized so as to form the N and S poles in the right and left directions of the figure. Consequently, the Co—Pt film 18 becomes a permanent magnet film 18. Strip-shaped soft magnetic films 44 similar to those of the above-mentioned second embodiment are formed in approximately the same region as the permanent magnet film 18 on the permanent magnet film 18. Subsequently, an insulation film 5 is formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com