Ferroelectric thin film element, piezoelectric actuator and liquid discharge head

a technology of ferroelectric thin film and actuator, which is applied in the direction of piezoelectric/electrostrictive device details, device material selection, device details, etc., can solve the problems of increasing the spontaneous polarization unable to improve the residual polarization or fatigue resistance and unable to obtain satisfactory device characteristics of the ferroelectric thin film. , to achieve the effect of improving the characteristics of the ferroelectric thin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

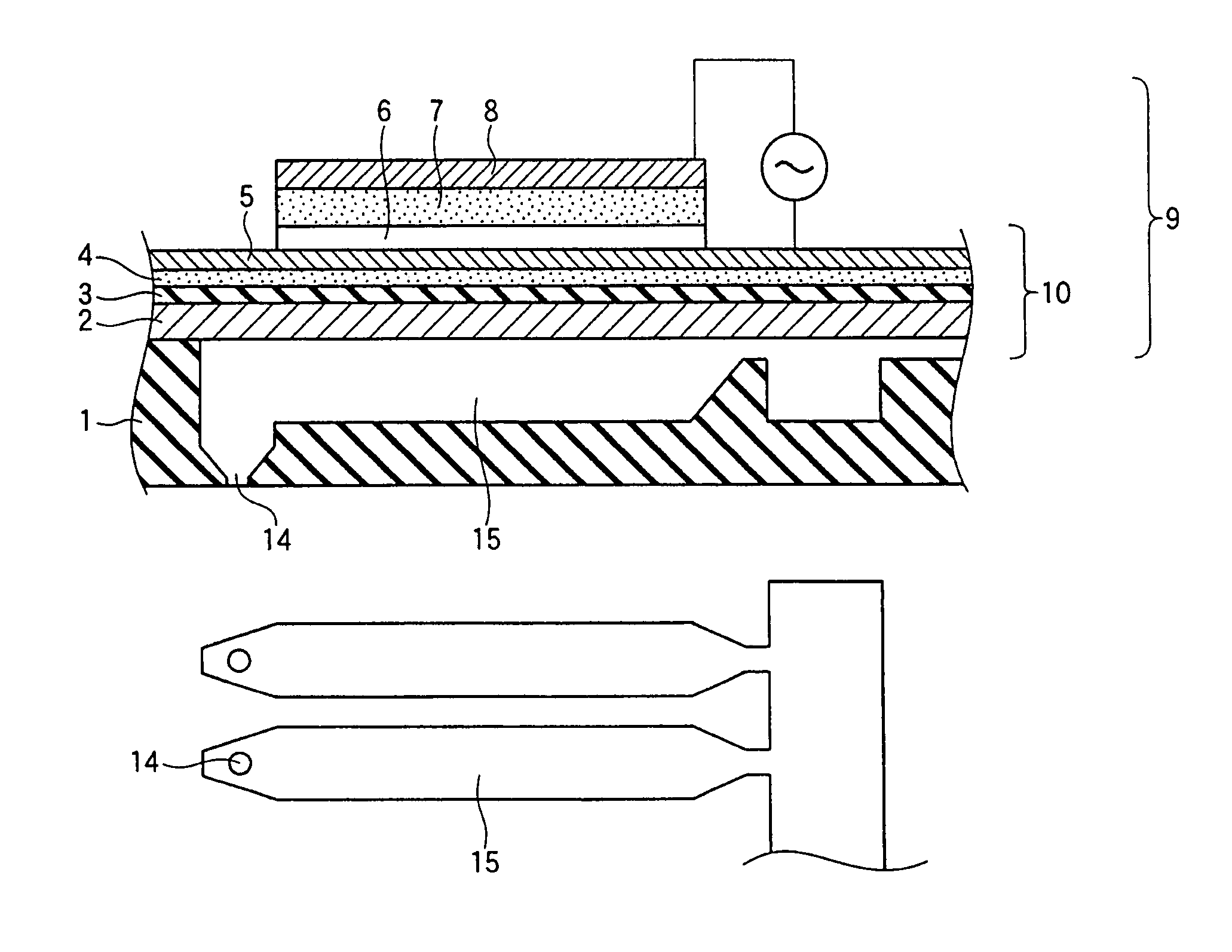

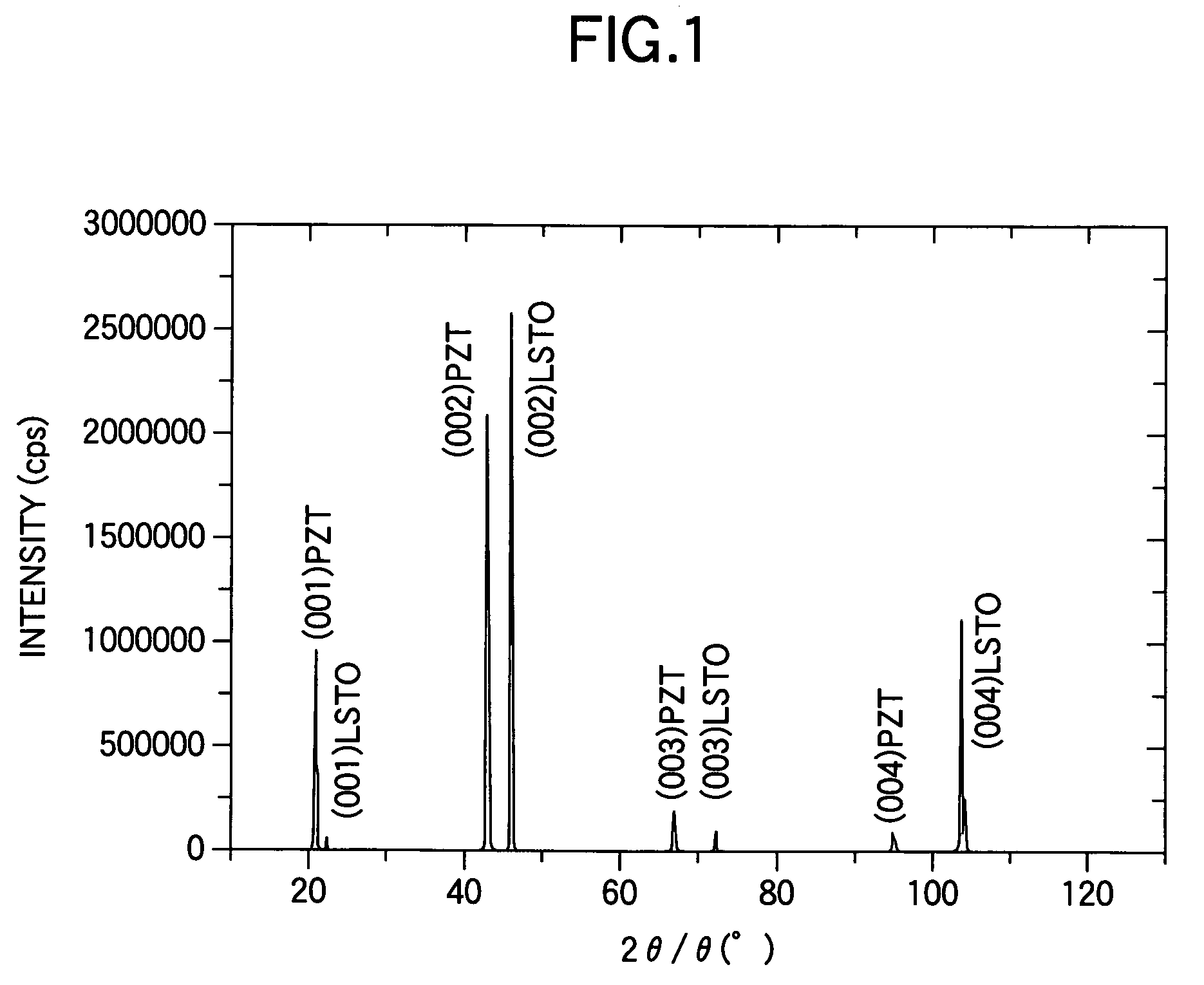

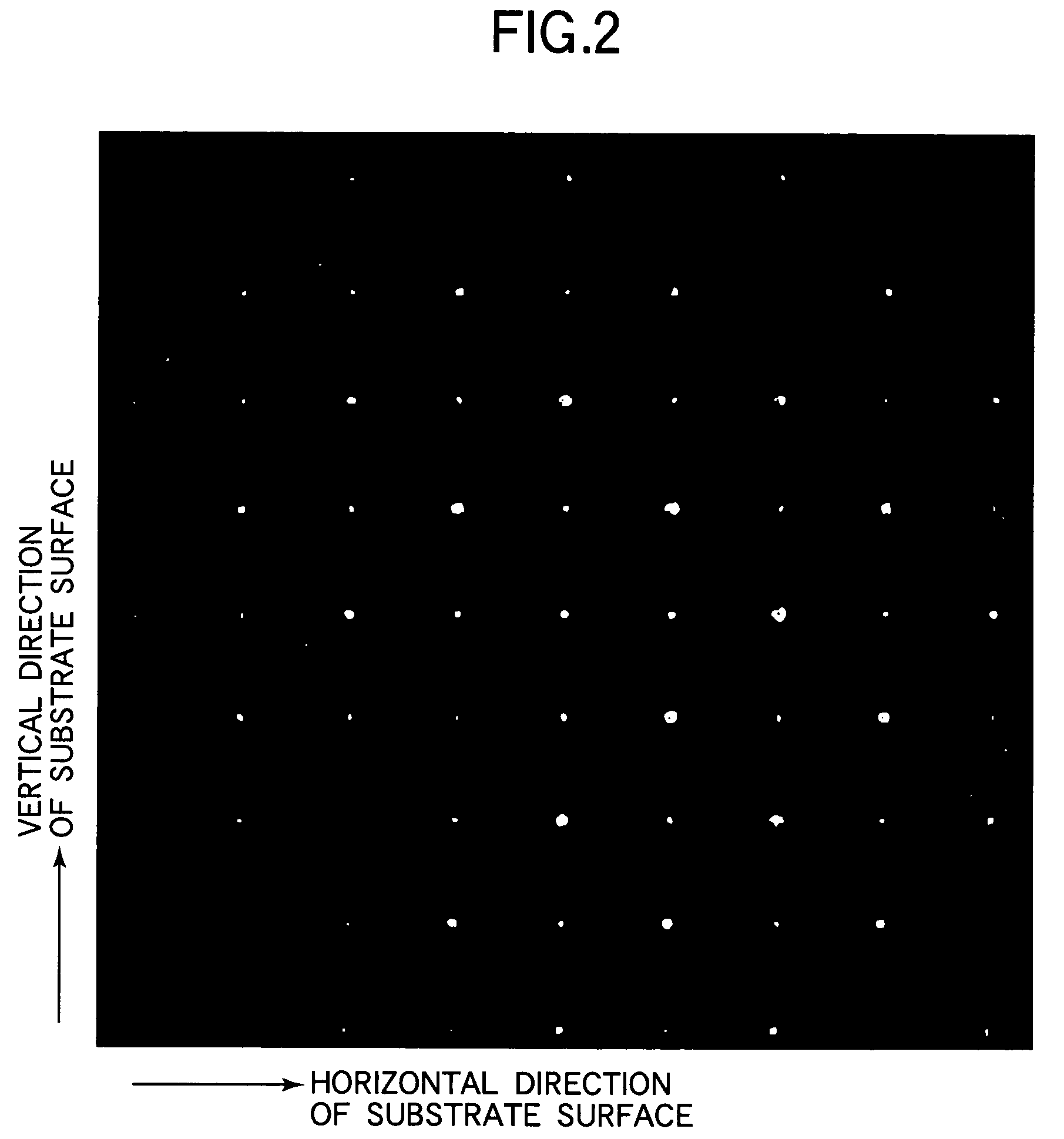

[0083]On a substrate (single crystal growing substrate) (La0.038, Sr0.962)TiO3 (100) serving also as an electrode, a PZT thin film of a thickness of 70 nm was epitaxially grown as an epitaxial ferroelectric thin film by a sputtering apparatus using an RF magnetron method, thereby obtaining a ferroelectric thin film element. In this operation, there were employed a substrate temperature of 600° C., an argon / oxygen ratio of 30 / 1 at film formation, a gas pressure of 0.2 Pa, an RF power of 0.8 W / cm2 at film formation and a cooling speed after film formation of 100° C. / min until 180° C. or lower was reached, and a pre-sputtering prior to film formation was conducted for 3 minutes with an RF power of 0.3 W / cm2. The PZT thin film, constituting the epitaxial ferroelectric thin film, had a composition of Pb(Zr0.52, Ti0.48)O3. The single crystal property of the PZT thin film of the thus prepared ferroelectric thin film element was measured by XRD. The obtained result is shown in FIG. 1. Based...

example 2

[0087]On a substrate (single crystal growing substrate) (La0.038, Sr0.962)TiO3 (100) serving also as an electrode, a PZT thin film of a thickness of 70 nm was epitaxially grown as an epitaxial ferroelectric thin film by a sputtering apparatus using an RF magnetron method, thereby obtaining a ferroelectric thin film element. In this operation, there were employed a substrate temperature of 600° C., an argon / oxygen ratio of 30 / 1 at film formation, a gas pressure of 0.2 Pa, an RF power of 0.8 W / cm2 at film formation and a cooling speed after film formation of 80° C. / min until 180° C. or lower was reached, and a pre-sputtering prior to film formation was conducted for 30 minutes with an RF power of 0.3 W / cm2. The PZT thin film, constituting the epitaxial ferroelectric thin film, had a composition of Pb(Zr0.52, Ti0.48)O3. The single crystal property of the PZT thin film of the thus prepared ferroelectric thin film element was measured by XRD. The obtained result is shown in FIG. 1. Based...

example 3

[0091]A mirror polished Si (100) of 15 mm square was employed as a substrate, and its surface was at first etched with tetramethylammonium hydroxide (also represented as TMAH) (manufactured by Kanto Chemical Co.) for 10 minutes at room temperature, then washed with purified water and rinsed with an acetone vapor bath. Then, on this substrate, a YZT thin film of a thickness of 10 nm was formed by a sputtering apparatus using an RF magnetron method at a substrate temperature of 800° C. An XRD measurement after film formation confirmed that the YSZ film had a crystal orientation rate of 99% or higher in a [100] direction. Then a Pt film of 100 nm as a lower electrode was formed by sputtering at a substrate temperature of 600° C. An XRD measurement after film formation confirmed that the Pt had a crystal orientation rate of 97% or higher in a [111] direction. Then, on these laminated films, a buffer layer of [PbTiO3] (also represented as PT) of 7 nm was formed with a sputtering apparatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com