A high Curie point low-temperature co-fired piezoelectric ceramic formula and preparation method

A technology of low-temperature co-firing and piezoelectric ceramics, applied in the field of piezoelectric ceramics, can solve problems such as high coercive field, low Curie temperature, and low Curie point, so as to improve piezoelectric performance, reduce sintering temperature, and improve Effect of Curie temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

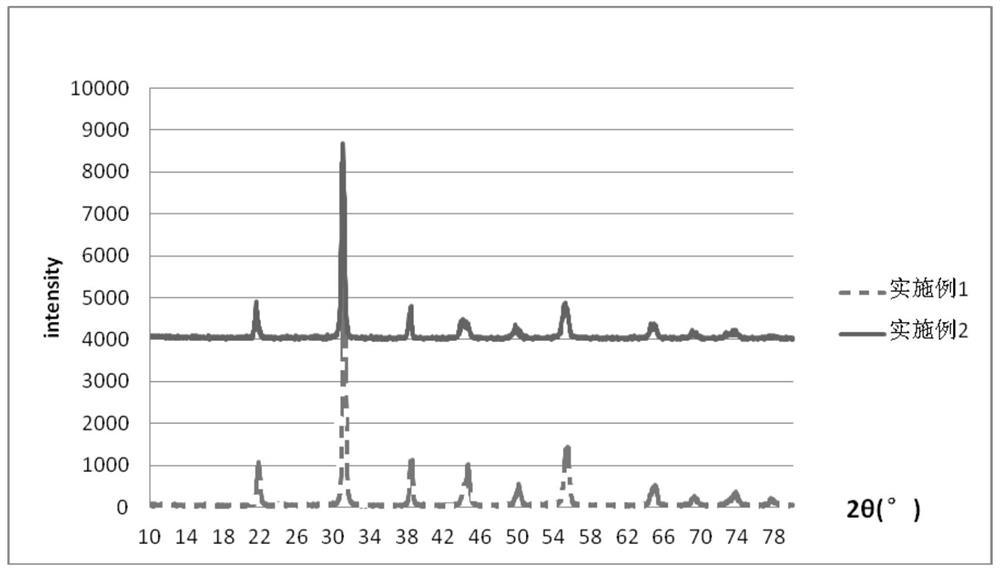

Embodiment 1

[0050] Embodiment 1: a preparation method of high Curie point and low temperature co-fired piezoelectric ceramics, comprising the following steps:

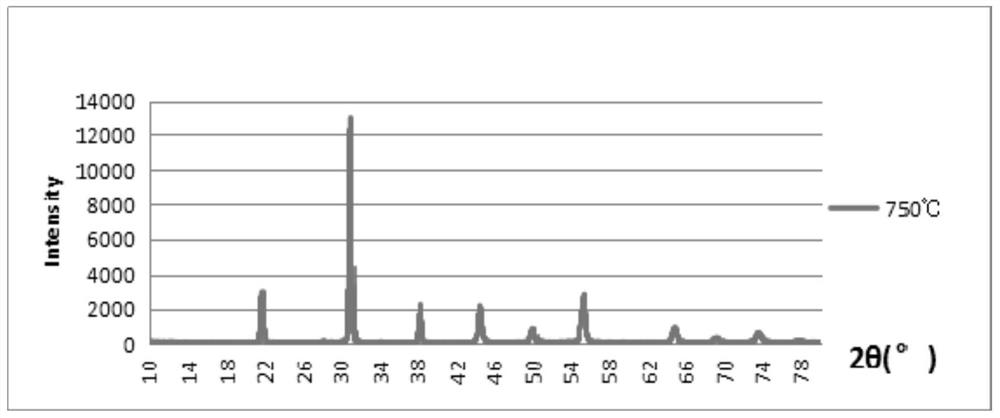

[0051] S1: Preparation of Ba(Mg 1 / 2 W 1 / 2 )O 3 Pre-fired powder

[0052] According to the chemical formula Ba(Mg 1 / 2 W 1 / 2 )O 3 Weigh analytically pure BaCO 3 , Mg(CH 3 COO) 2 ·6H 2 O, WO 3 Submicron powder, the above raw materials are mixed and ball-milled with a ball mill for 6-8 hours under the condition of ethanol as a dispersant, and then dried to obtain the mixed powder of the reacted precursor, and then the mixed powder is placed in an alumina crucible at 750 ° C After pre-sintering for 2h, the ball mill pulverized for 6h to obtain the glassy phase Ba(Mg) of the perovskite structure. 1 / 2 W 1 / 2 )O 3 Pre-fired powder;

[0053] S2: Preparation of LiNbO 3 Pre-fired powder

[0054] According to the chemical formula LiNbO 3 Weigh analytically pure LiCO 3 , Nb 2 O 5 For sub-micron powder, the above raw materi...

Embodiment 2

[0075] Embodiment 2: a preparation method of high Curie point and low temperature co-fired piezoelectric ceramics, comprising the following steps:

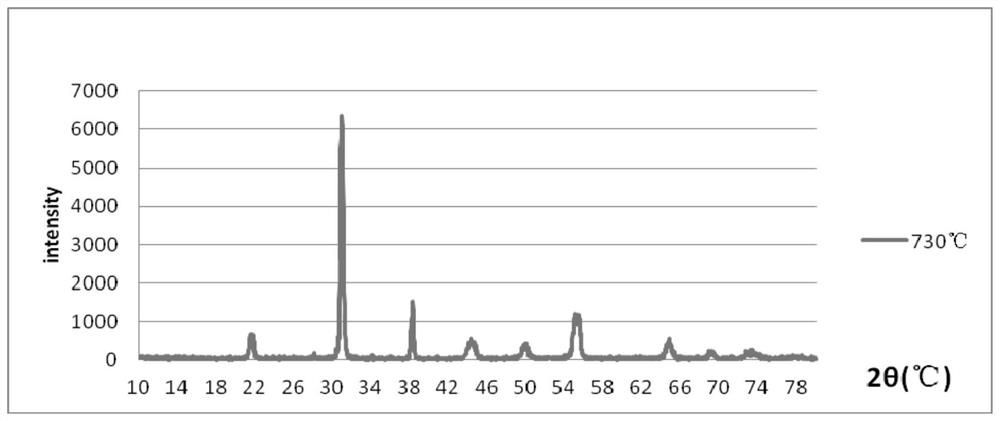

[0076] S1: Preparation of Ba(Mg 1 / 2 W 1 / 2 )O 3 Pre-fired powder

[0077] According to the chemical formula Ba(Mg 1 / 2 W 1 / 2 )O 3 Weigh analytically pure BaCO 3 , Mg(CH 3 COO) 2 ·6H 2 O, WO 3 For sub-micron powder, the above raw materials are mixed and ball-milled with a ball mill for 8 hours under the condition of using ethanol as a dispersant, and then dried to obtain the mixed powder of the reacted precursor, and then the mixed powder is placed in an alumina crucible and pre-heated at 750 ° C. After sintering for 2h, the ball mill was pulverized for 6h to obtain the glassy phase Ba (Mg 1 / 2 W 1 / 2 )O 3 Pre-fired powder;

[0078] S2: Preparation of LiNbO 3 Pre-fired powder

[0079] According to the chemical formula LiNbO 3 Weigh analytically pure LiCO 3 , Nb 2 O 5 For sub-micron powder, the above raw materials w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com