Optical scanning device with at least one resin lens for controlling a beam waist position shift

a scanning device and a technology of resin lenses, applied in the direction of condensers, instruments, mountings, etc., can solve the problems of resin lenses being susceptible to environmental conditions, changing shape, and degrading image quality,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

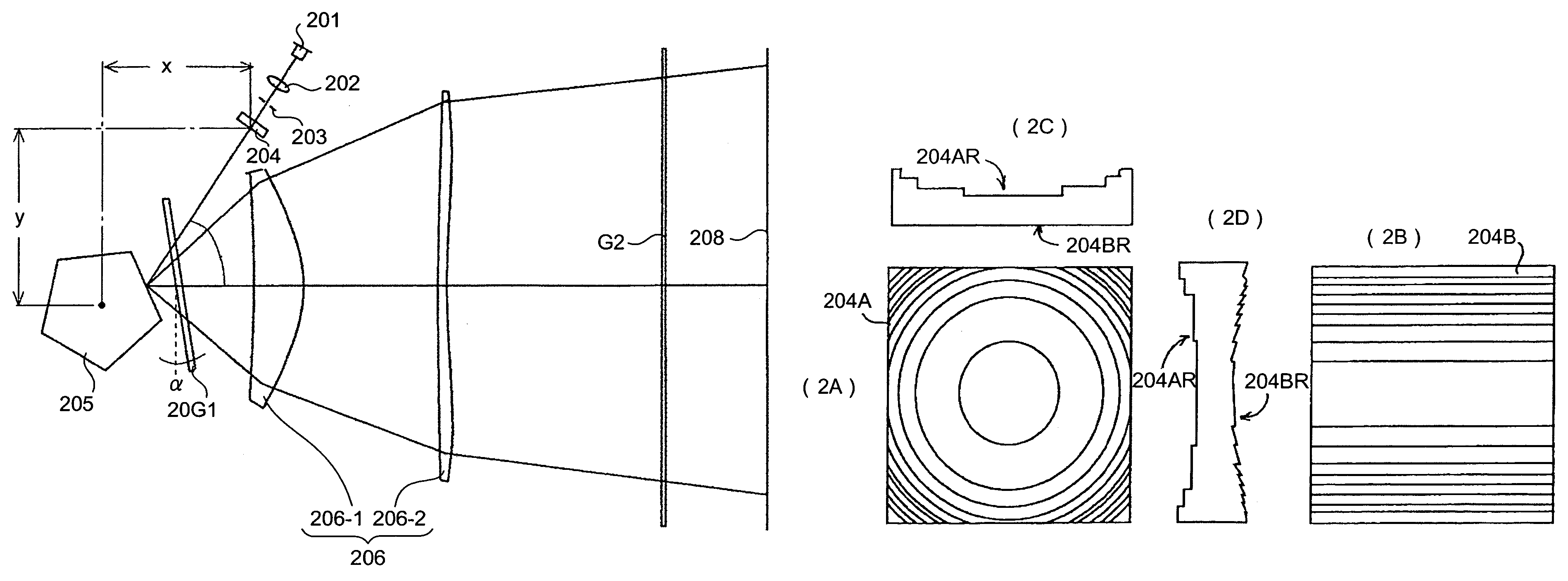

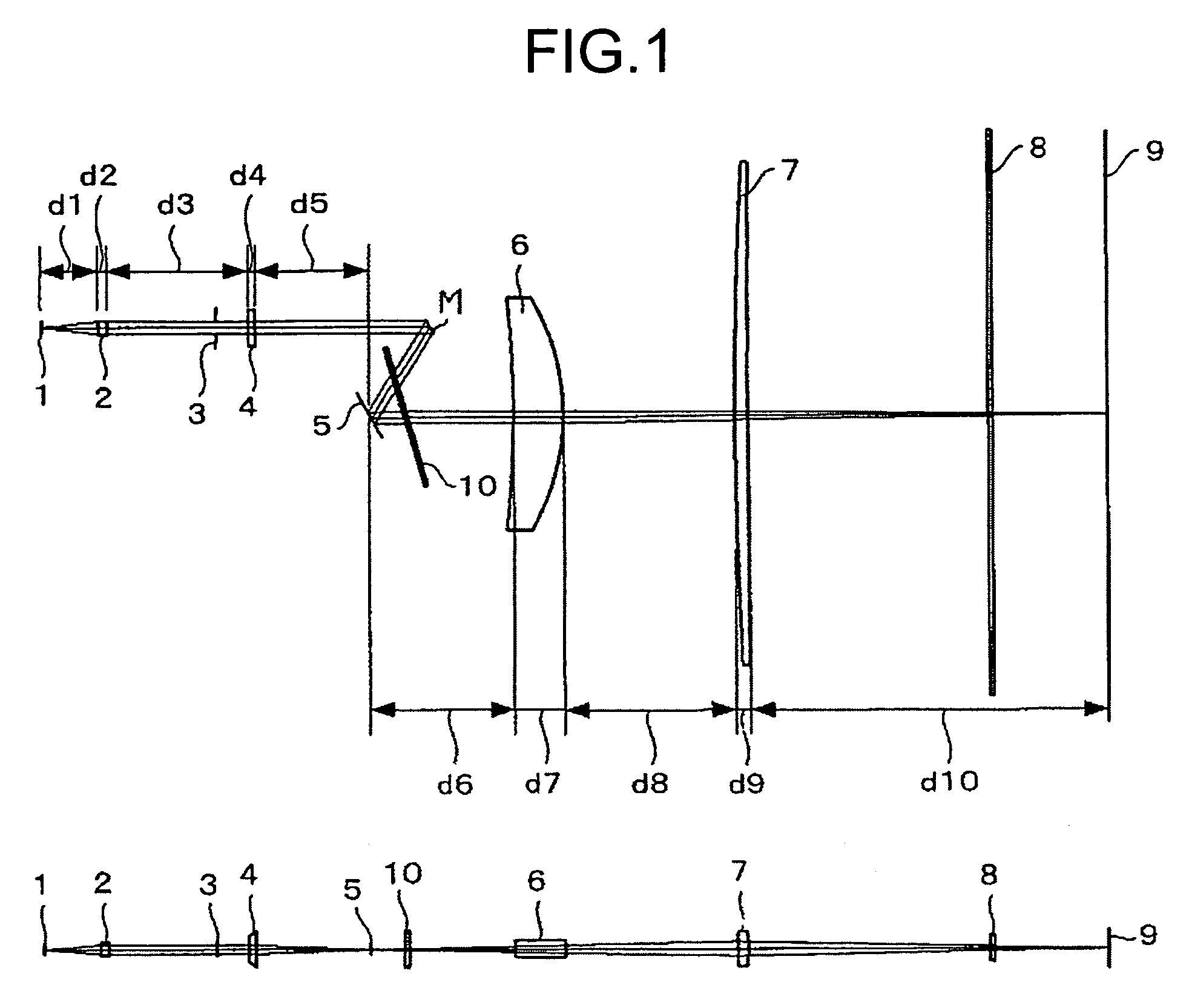

Method used

Image

Examples

first working example

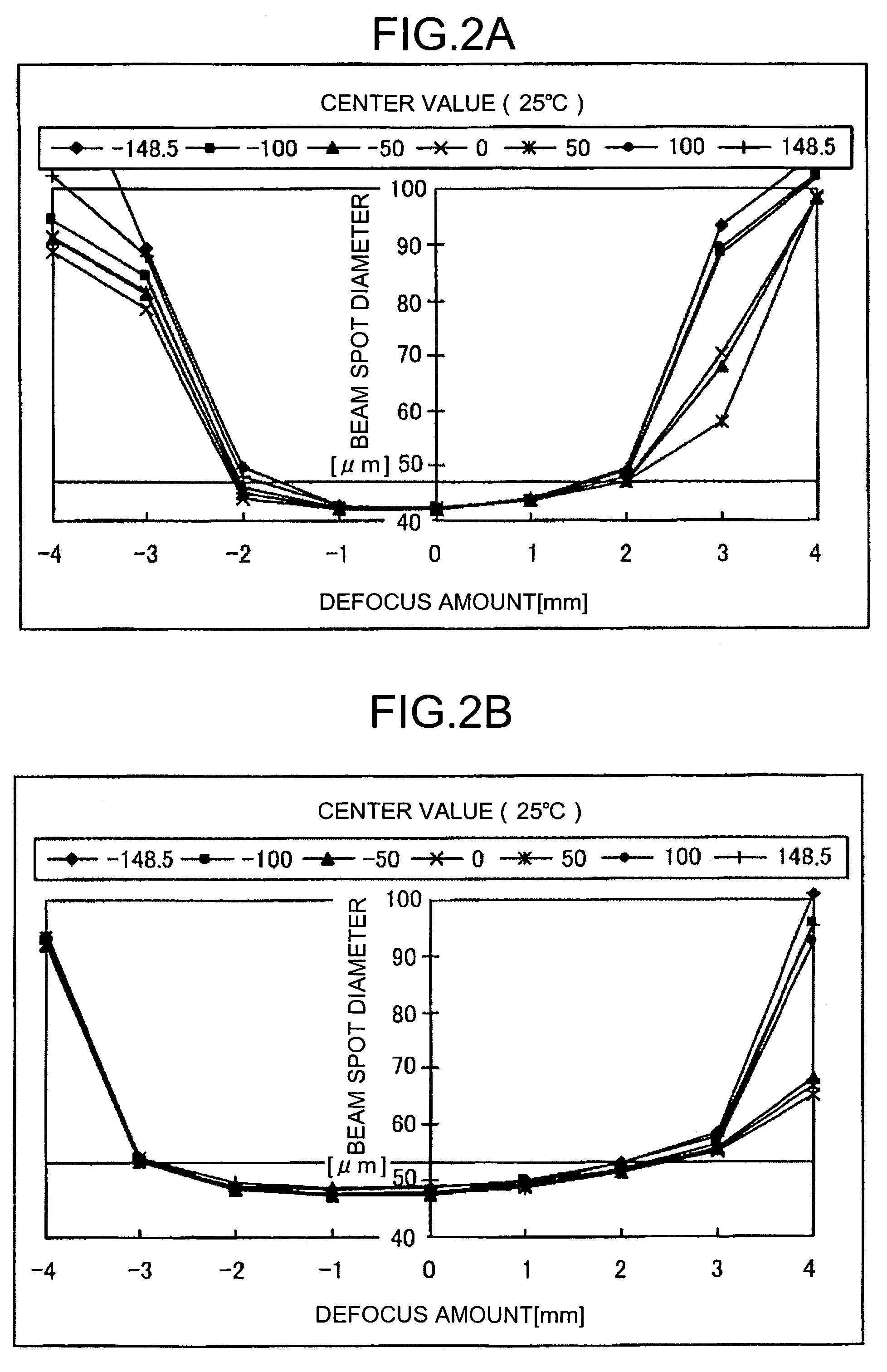

[0168]The first working example of the embodiment will be explained now. The emission wavelength of the light source is 655 nm at 25° C. and 659 mm at 45° C.

[0169]The characteristics of the coupling lens 2 are explained first. The incident surface is a diffractive surface having concentric circular gratings. Phase function φ(h) of the diffractive surface is represented by Expression (12).

φ(h)=C1·h2 (12)

where, h is the distance from the optical axis, C1 is a phase coefficient. The value of the phase coefficient, C1, is as follows:

[0170]C1=−1.127E−02.

[0171]The exit surface is an aspherical surface represented by Expression (7), the values of R, K, A4, A6, A8, and A10 are as follows:

[0172]R=−34.32864

[0173]K=−71.517137

[0174]A4=−0.208422E−03

[0175]A6=0.651475E−05

[0176]A8=−0.238199E−06

[0177]A10=0.770435E−08

[0178]The characteristics of the first lens 4″ will be explained now. The surface of the first lens 4 that faces toward the light source 1 is a plane surface in the main scanning direct...

second working example

[0262]The second working example of the embodiment will be explained now. The emission wavelength of the light source is 655 nm at 25° C. and 659 nm at 45° C.

[0263]The coupling lens 2 is made of glass. The incident surface of the coupling lens 2 is a plane surface and the exit surface is an aspherical surface represented by Expression (7). The shape of the exit surface of the coupling lens 2 is optimized so as to correct the wavefront aberration. The value of the paraxial curvature radius R is −18.49. The light beam emerging from the coupling lens 2 is virtually a parallel beam.

[0264]The characteristics of the first lens 4″ will be explained now. The incident surface of the first lens 4 is a toroidal surface having a curvature radius of −246.5 in the main scanning direction and −52.2 in the sub-scanning direction. The incident surface of the first lens 4 is a plane surface having an elliptical diffractive surface. The phase function φ(y,z) of the diffractive surface is represented b...

third working example

[0282]The second working example of the embodiment will be explained now. The emission wavelength of the light source is 655 nm at 25° C. and 659 nm at 45° C.

[0283]The coupling lens 2 is made of glass. The incident surface of the coupling lens 2 is a plane surface and the exit surface is an aspherical surface represented by Expression (7). The shape of the exit surface is optimized so as to correct the wavefront aberration. The value of the paraxial curvature radius R is the same as for the second working example, that is, −18.49. The light beam emerging from the coupling lens 2 is virtually a parallel beam.

[0284]The characteristics of the first lens 4″ will be explained now. The incident surface of the first lens 4 is a rotationally symmetrical spherical surface having a curvature radius of −246.5 with concentric diffraction gratings provided thereon as a diffractive surface. The diffractive surface is represented by Expression (12) in terms of its distance, h, from the optical axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com