Lead acid battery with gelled electrolyte formed by filtration action of absorbent separators and method for producing it

a technology of absorbent separator and gelled electrolyte, which is applied in the direction of non-aqueous electrolyte cells, cell components, sustainable manufacturing/processing, etc., can solve the problems of electrolyte loss, water loss, corresponding loss of water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

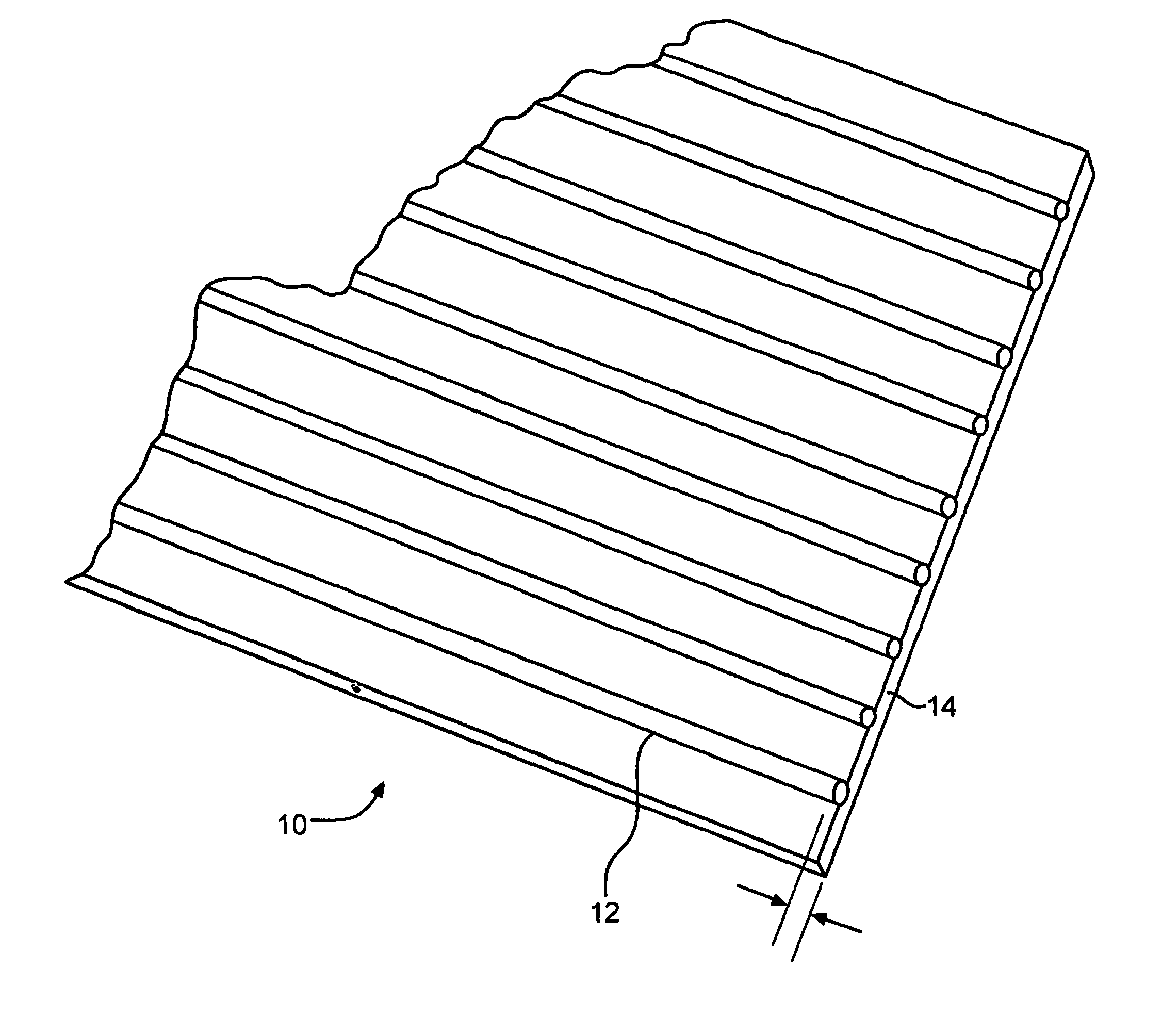

[0055]Thirty-three test batteries of type U2 (50 Ah) were made to illustrate how the present invention can be carried out on commercial battery making apparatus. Special absorbent separator / spacer material was prepared to produce these batteries. The separator / spacer spacer material was produced from an absorbent glass / synthetic fiber mat which had a surface area of 0.9 m2 / g, an average pore size of about 4 μm, a maximum pore size of about 25 μm, and contained 85% by weight of glass fibers and 15% by weight of organic fibers. The base material, which is commercially available from Hollingsworth & Vose Company under the designation “BG-089GB054”, had a basis weight of 89 grams per square meter and a thickness at 10 kPa of about 0.54 mm. The base material was subjected to a corrugating process which involved saturating it with a 5% by weight aqueous solution of sodium silicate and, while it was wet with the sodium silicate solution, passing it through a set of metallic corrugating rol...

example 2

[0064]Six Group 24 monopoly VRLA batteries were produced and filled with sulfuric acid containing 1 percent by weight of silica from unmilled, never dried precipitated silica slurry. The batteries contained absorptive all glass mat separator grade BG26067 available from Hollingsworth & Vose Company. The separator surfaces were in direct contact with the plates. The fibers of the separator had a surface area of 1.0 M2 / g,. The separator had an average pore size of about 4-6 μm, and a maximum pore size of about 25 μm The batteries were container formed without any difficulty. They were discharged at the 20-minute rate and averaged about 23 minutes of discharge time. Later, the batteries were discharged at the 5-hour rate and performed normally, delivering about 105 percent of their rated capacity, on average. One of the batteries was opened, and normally saturated separators were found inside, i.e., the separator material was saturated with liquid electrolyte. A layer of gel was formed...

example 3

[0066]Five factory produced Motive Power thirteen plate cells, capacity of 510 Ah (85 Ah per positive plate), were used in further investigation of the instant invention. The separator between the plates comprised of a layer of latex bonded 13 μm glass fiber veil having a nominal thickness of 0.38 mm adjacent to the positive plate, a spacer layer, nominal thickness 40 thousandths of an inch, of a polymeric netting that is available from Malted under the designation Malted 55-3757, positioned next to the veil, a layer of H&V Energy Guard ® BG 180GB117 glass / synthetic separator material, nominal thickness 1.17 mm, next to the netting, and a final spacer layer of Malted 55-3757 polymeric netting adjacent the negative plate.

[0067]Cell 1 was a control cell and was first used to determine the amount of electrolyte that would be absorbed by the separator and the active material in the cells. Cell 1 was filled with 5.35 liters of sulfuric acid having a specific gravity of 1.220. The unabsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific gravity | aaaaa | aaaaa |

| specific gravity | aaaaa | aaaaa |

| specific gravity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com