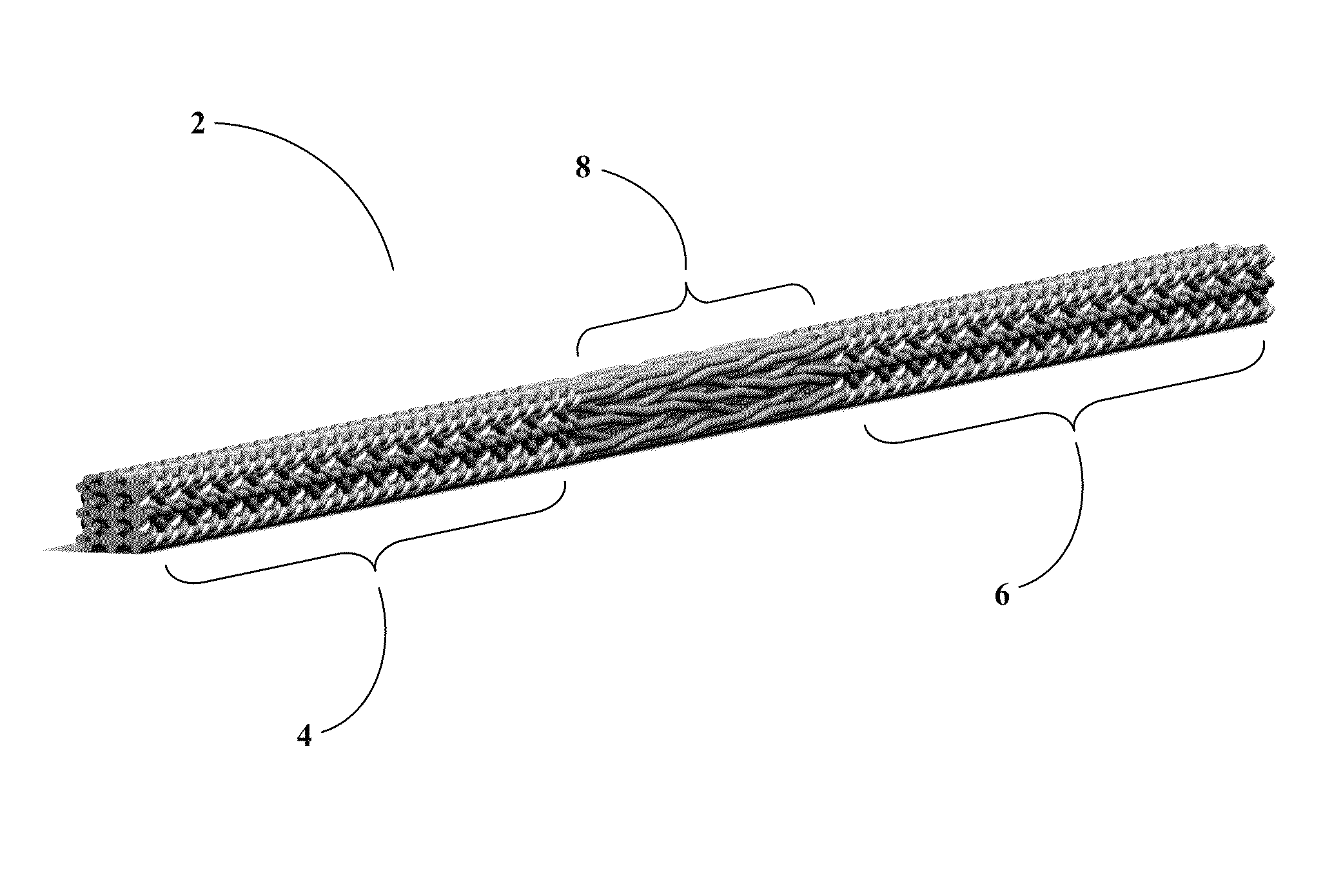

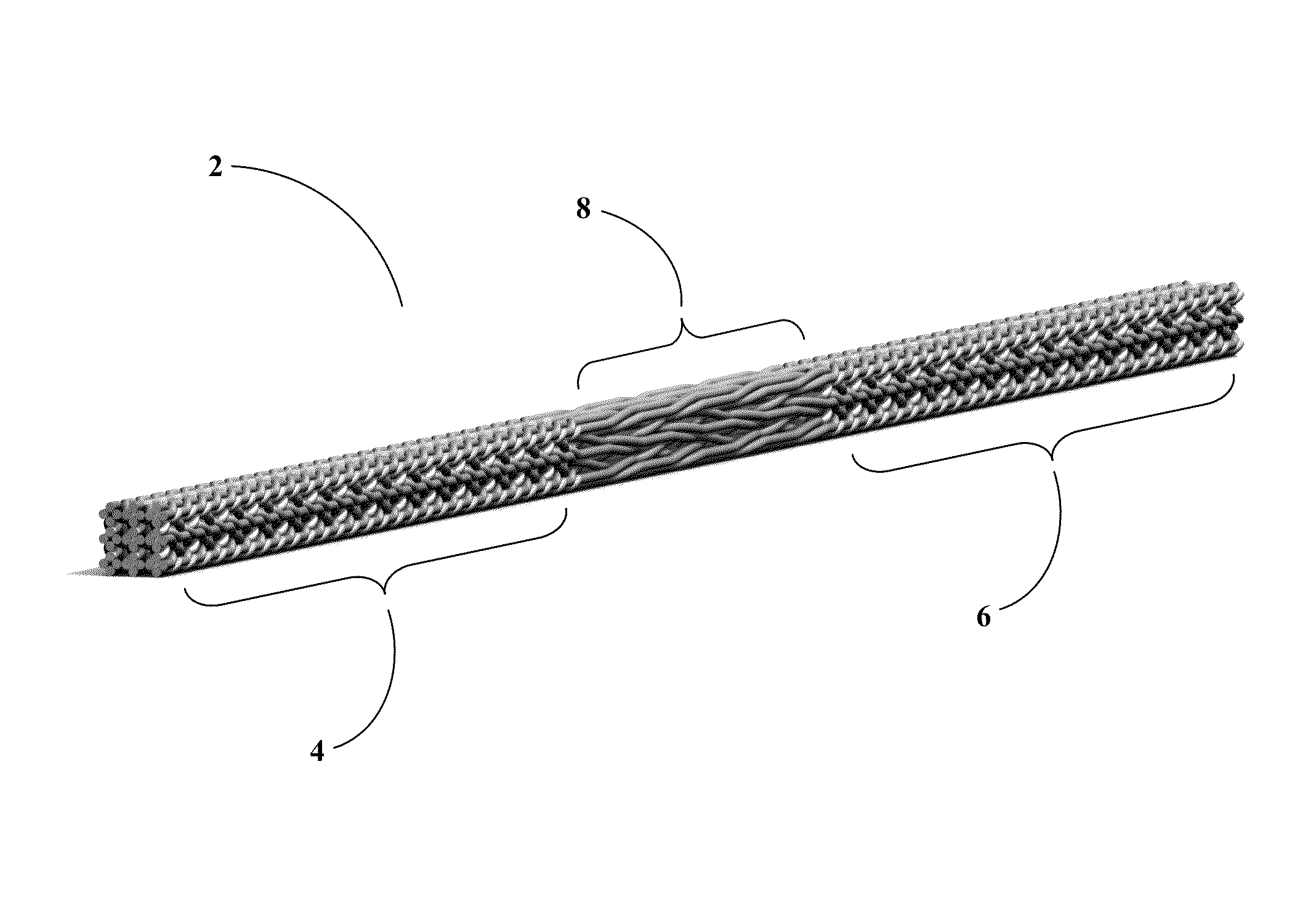

Ligament and tendon replacement constructs and methods for production and use thereof

a technology of ligament and tendon, which is applied in the direction of ligaments, shoulder joints, prostheses, etc., can solve the problems of limited tissue available for harvesting, low production efficiency, and inability to meet the needs of patients,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Microfiber Matrices

[0050]An electrospinning technique was used to produce biodegradable non-woven fiber scaffold with an approximate thickness of 0.5 mm. In this procedure, PLAGA (50:50) was dissolved in methylene chloride to produce a 1:4 weight:volume solution. In the electrospinning process, a 20 kV electric potential was applied to the polymer solution and a collection screen to create an electric field. The polymer solution was then sprayed onto the collection screen for 30 minutes. This resulted in a uniform non-woven microfiber matrix attached on the screen. The matrix was removed, and cut into 1 cm2 pieces.

example 2

[0051]Three-dimensional fibrous matrices were fabricated using a 3-D braiding process as described by Ko, F. K. in Textile Structural Composites, eds. Chou, T. W. and Ko., F. K. (Elsevier, Amsterdam, 1989). In this procedure, PLAGA fiber (5:95 PLAGA) was laced to produce yarns with a fiber density of 30 and 60 fibers per yarn. Yarns were then placed in a custom built braiding loom with a 6 by 12 carrier arrangement. Sequential motion of the carriers [alternating rows and columns] resulted in the formation of two rectangular 3-D braids: a 30 yarn braid [braid #1] and a 60 yarn braid [braid #2].

example 3

[0052]Matrices were evaluated in a 2-week cell culture study using fibroblasts and primary culture osteoblasts. All matrices were UV sterilized for 24 hours per side prior to cell culture. Primary culture osteoblasts isolated from neonatal rat calvaria were grown to confluence in Ham's F-12 medium (GIBCO), supplemented with 12% fetal bovine serum [FBS] (Sigma), as described by Jarcho, M. Clin. Ortho. 1981 157:259. Mouse fibroblast cells (BALB / C C7 purchased from ATCC: Arlington Va.) were grown to confluence in DMEM supplemented with 10% FBS. Cells were seeded onto UV sterilized matrices at a density of 5×105 cells / matrix. Cells were cultured on the matrices for 1, 3, 7, 10, and 14 days, and were maintained with DMEM (10% FBS). At the various time points, cells were fixed in glutaraldehyde, and dehydrated through a series of ethanol dilutions. Samples for scanning electron microscopy [SEM] were sputter coated with gold (Denton Desk-1 Sputter Coater). Matrix and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| pore diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com