Biosensor and method for producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

(Fructose Sensor I)

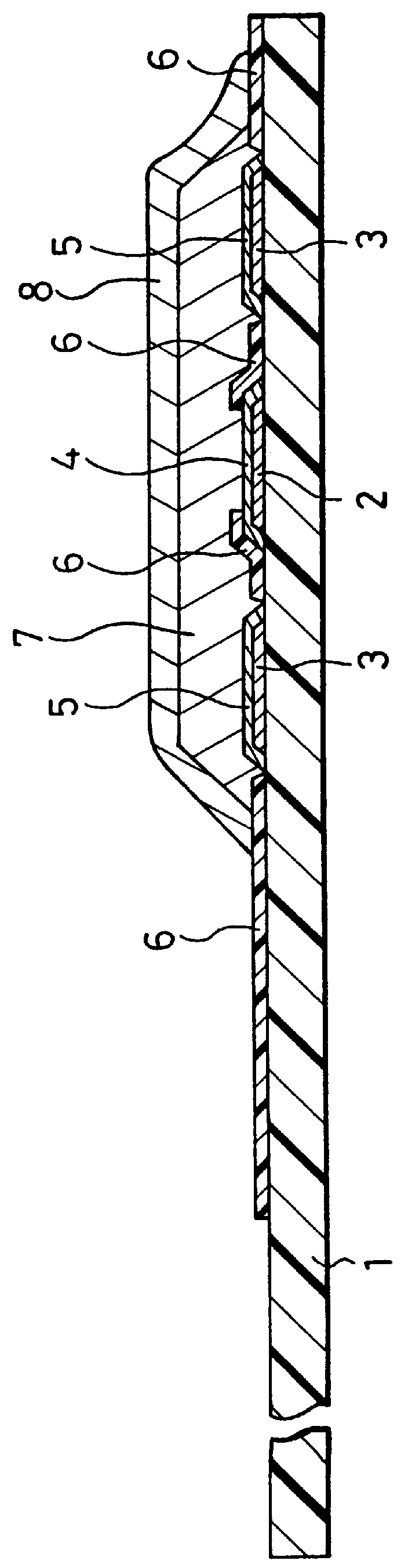

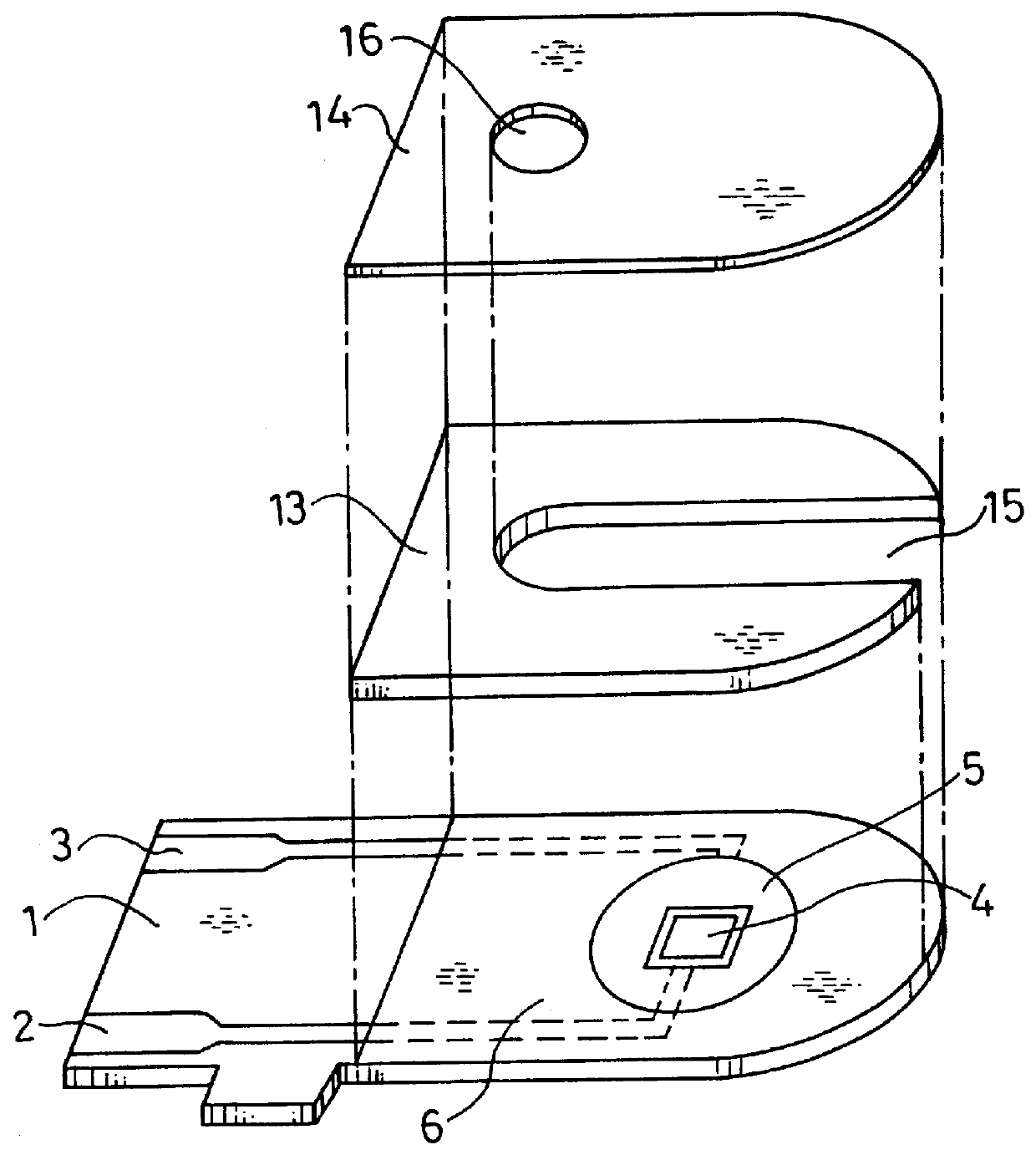

FIG. 1 is a cross-sectional side view showing a fructose sensor prepared in accordance with an embodiment of the present invention with its cover and a spacer omitted, and FIG. 2 is an exploded perspective view of the fructose sensor with its reaction layer omitted.

An insulating base i is made of polyethylene terephthalate. On the insulating base 1, there are provided lead wires 2 and 3 of silver by means of screen printing. An electrode system including a working electrode 4 and a counter electrode 5 is also formed on the insulating base 1 by printing an electrically-conductive carbon paste containing a resin binder. Further, an insulating layer 6 is formed on the insulating base 1 by printing an insulating paste. The insulating layer 6 maintains areas of the exposed regions of the working electrode 4 and the counter electrode 5 constant, and partly covers the lead wires 2 and 3.

After the electrode region was prepared in this manner, a mixed aqueous solution comp...

example 2

(Fructose Sensor II)

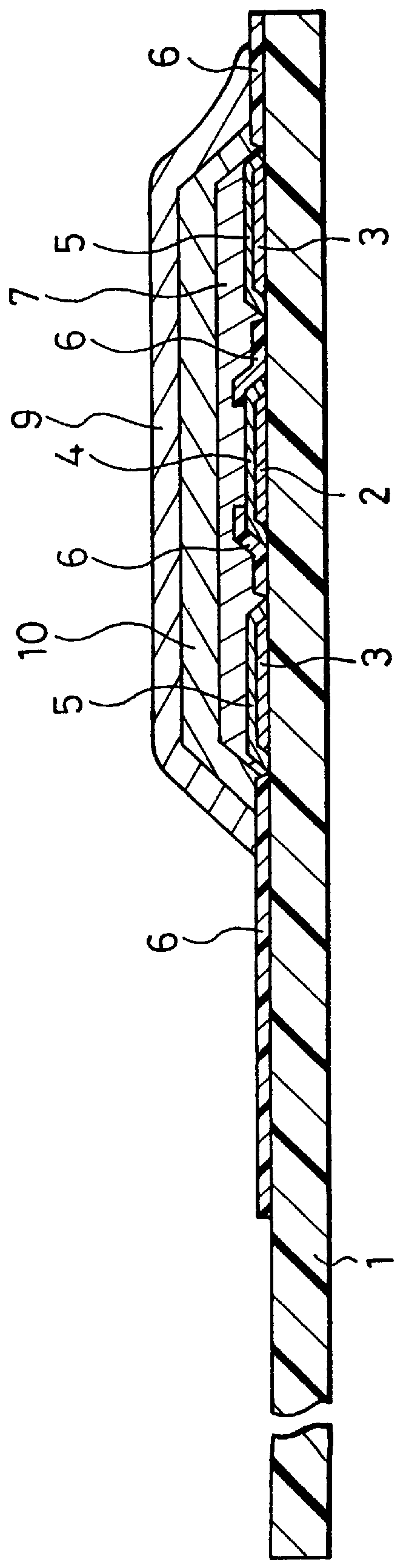

In a manner similar to that in Example 1, an electrode system composed of the working electrode 4 and the counter electrode 5 was formed on the insulating base 1 made of polyethylene terephthalate by means of screen printing, as shown by FIG. 3. By dropping an aqueous solution (0.5 wt %) of CMC on the electrode system and then drying, a CMC layer was formed. Next, an aqueous solution of the enzyme FDH and the electron acceptor potassium ferricyanide was spread over the CMC layer and then dried to form an FDH-potassium ferricyanide-CMC layer 7. In this case however, the CMC, the FDH as well as the potassium ferricyanide were partially mixed together and formed in a thin film of a thickness of several microns. That is, when the above-mentioned aqueous solution was dropped on the CMC layer, the previously formed CMC layer was once dissolved and then formed a layer 7 in a state partly mixed with the enzyme and the like during the subsequent drying process.

In this cas...

example 3

(Lactic Acid Sensor)

In a manner similar to that in Example 1, an electrode system was formed on the insulating base 1 made of polyethylene terephthalate by means of screen printing, as shown by FIG. 4. By dropping an aqueous solution (0.5 wt %) of CMC, which also dissolved the buffer, potassium dihydrogenphosphate and dipotassium hydrogenphosphate, on the electrode system and then drying, a buffer-CMC layer 11 was formed. Next, an ethanol solution (0.5 wt %) of PVP was spread over the buffer-CMC layer 11 so that it covered the layer, and then dried to form a PVP layer. An aqueous solution of lactic acid oxidase (available from TOYOBO Co., Ltd., hereinafter referred to LOD) as an enzyme and potassium ferricyanide as an electron acceptor was spread over the PVP layer and then dried. In this case, however, since the PVP layer was partly dissolved in the above-mentioned aqueous solution, an LOD-potassium ferricyanide-PVP layer 12 was formed. Further, since the ethanol employed for formi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydrophilicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com