Multi-beam optical scanner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

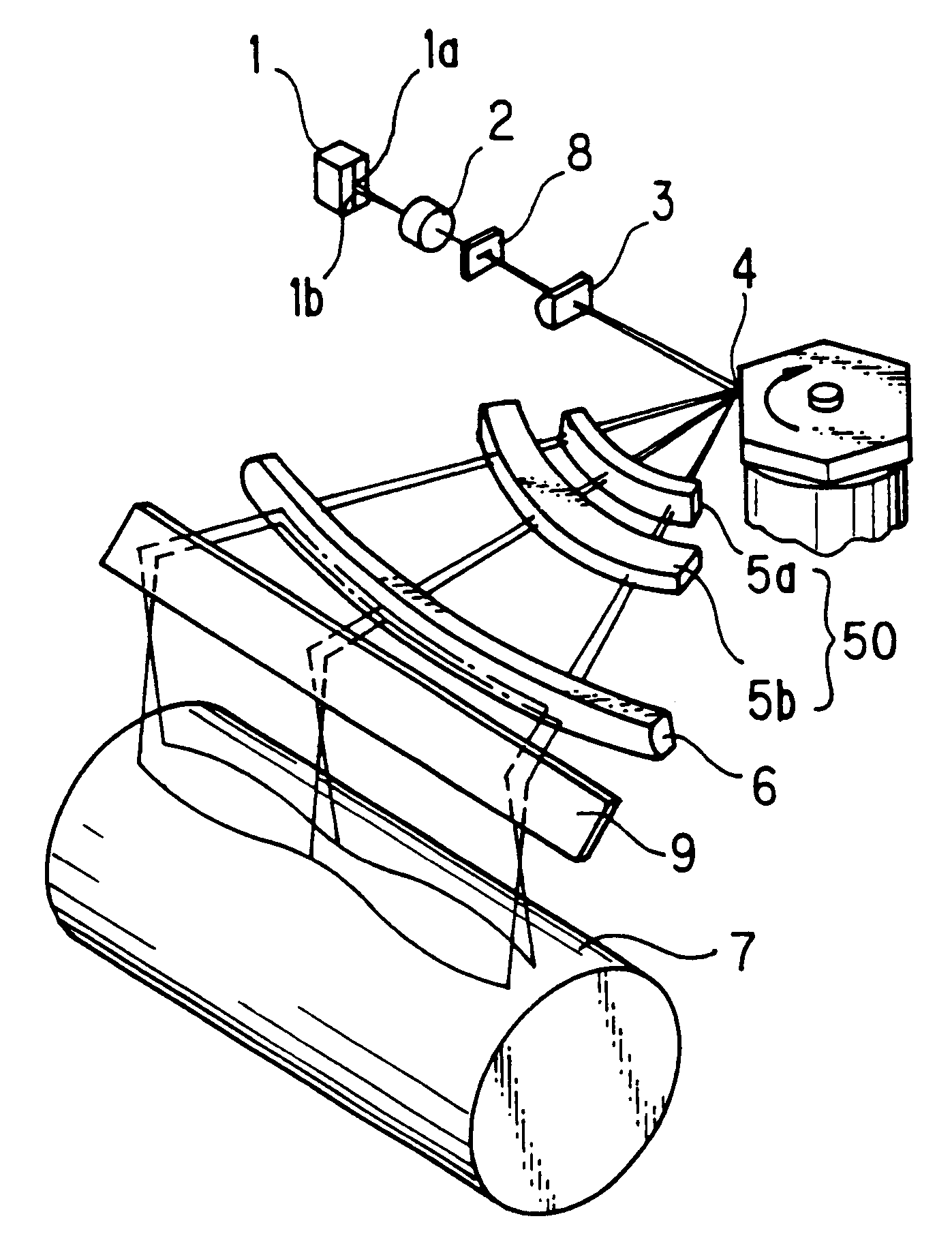

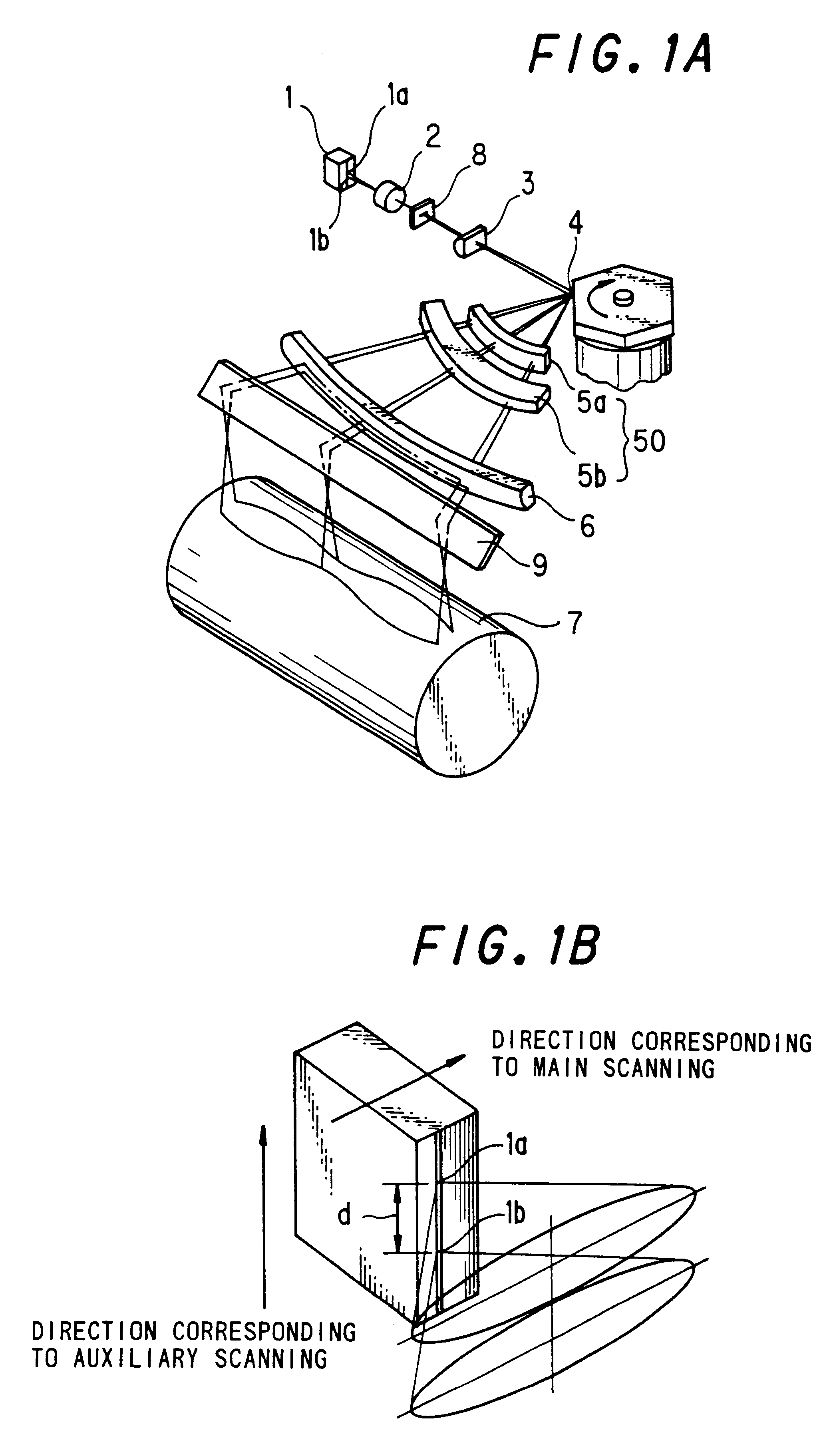

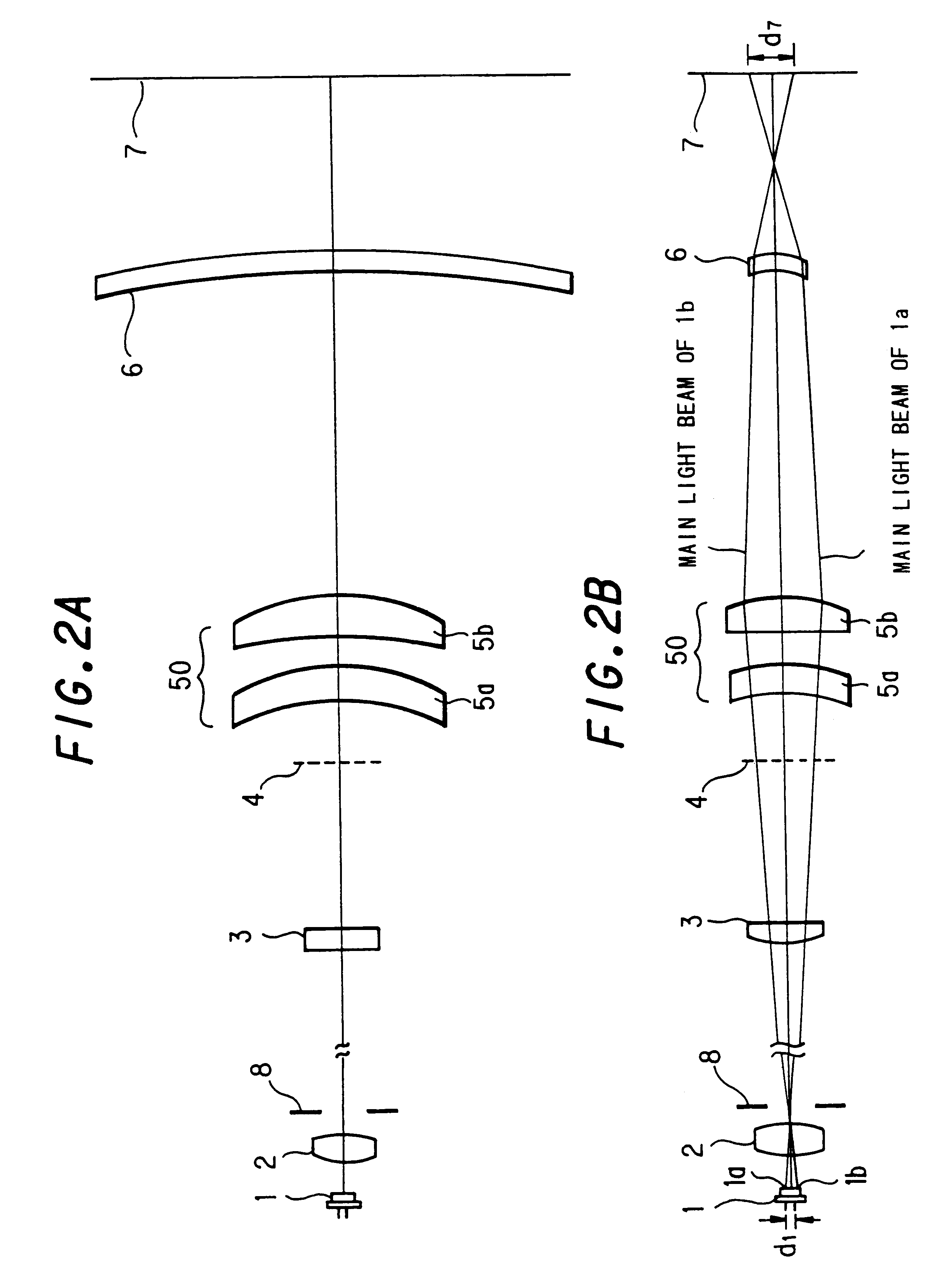

In FIG. 1A, a light source 1 for a multi-beam is, as shown in FIG. 1B, a monolithic semiconductor laser having two LD light emitting sections 1a and 1b provided therein so that the two light emitting sections 1a, 1b are arranged with a space d in a direction corresponding to the auxiliary scanning.

In FIG. 1A, both of two light fluxes radiated from the two LD light emitting sections 1a and 1b in the light source 1 for a multi-beam are converted to parallel ones by a collimate lens 2. The LD light emitting sections 1a and 1b in the light source 1 for a multi-beam are provided at positions each at an equal distance (d / 2) from the optical axis of the collimate lens 2 respectively.

The two light fluxes radiated from the collimate lens 2 are cut off in each of peripheral sections of the light fluxes by an aperture 8 for beam formation to enter a cylinder lens 3 as a first image-formation system.

The cylinder lens 3 has positive power only in a direction corresponding to the auxiliary scanni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com