High Q angular rate sensing gyroscope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

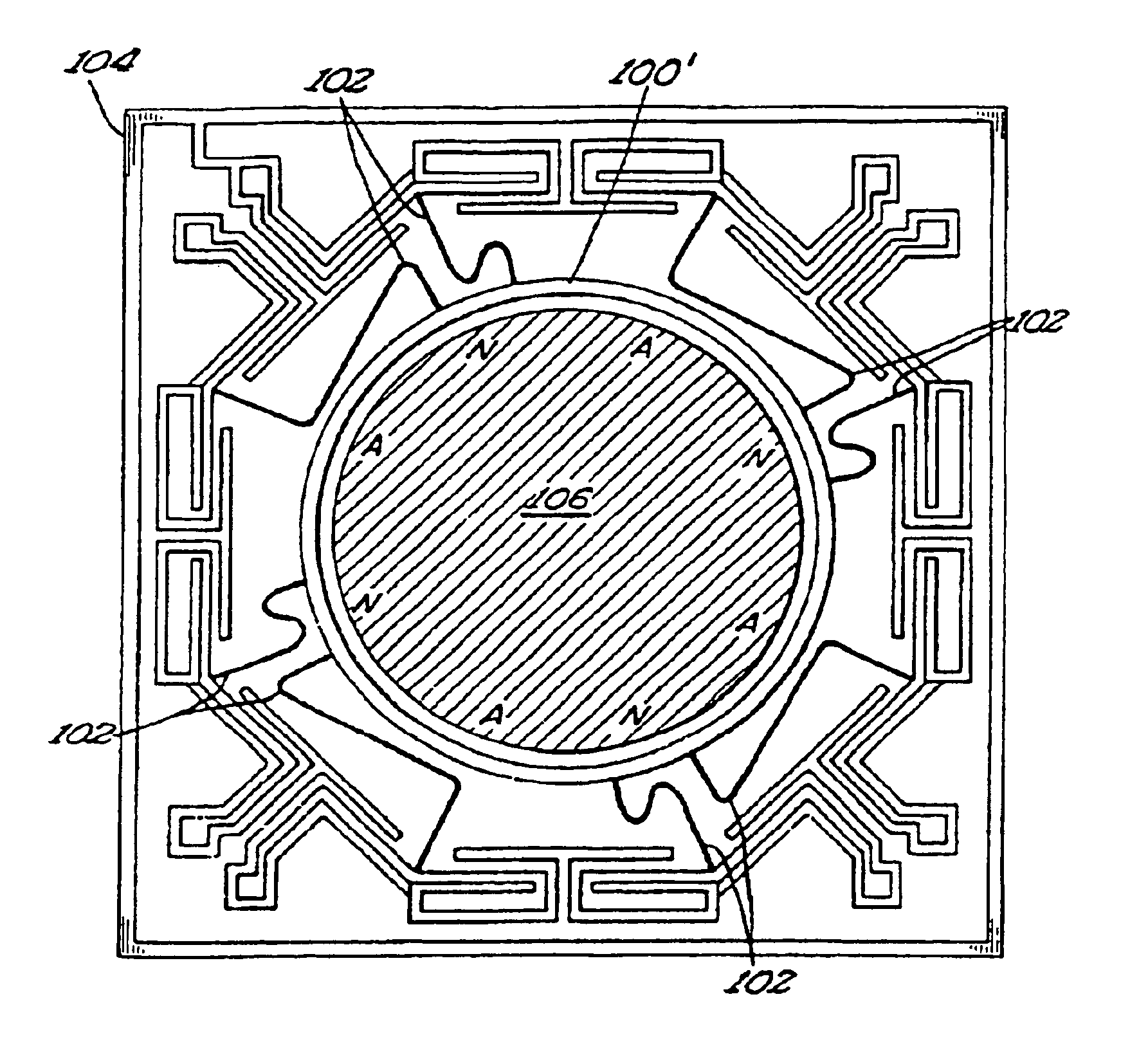

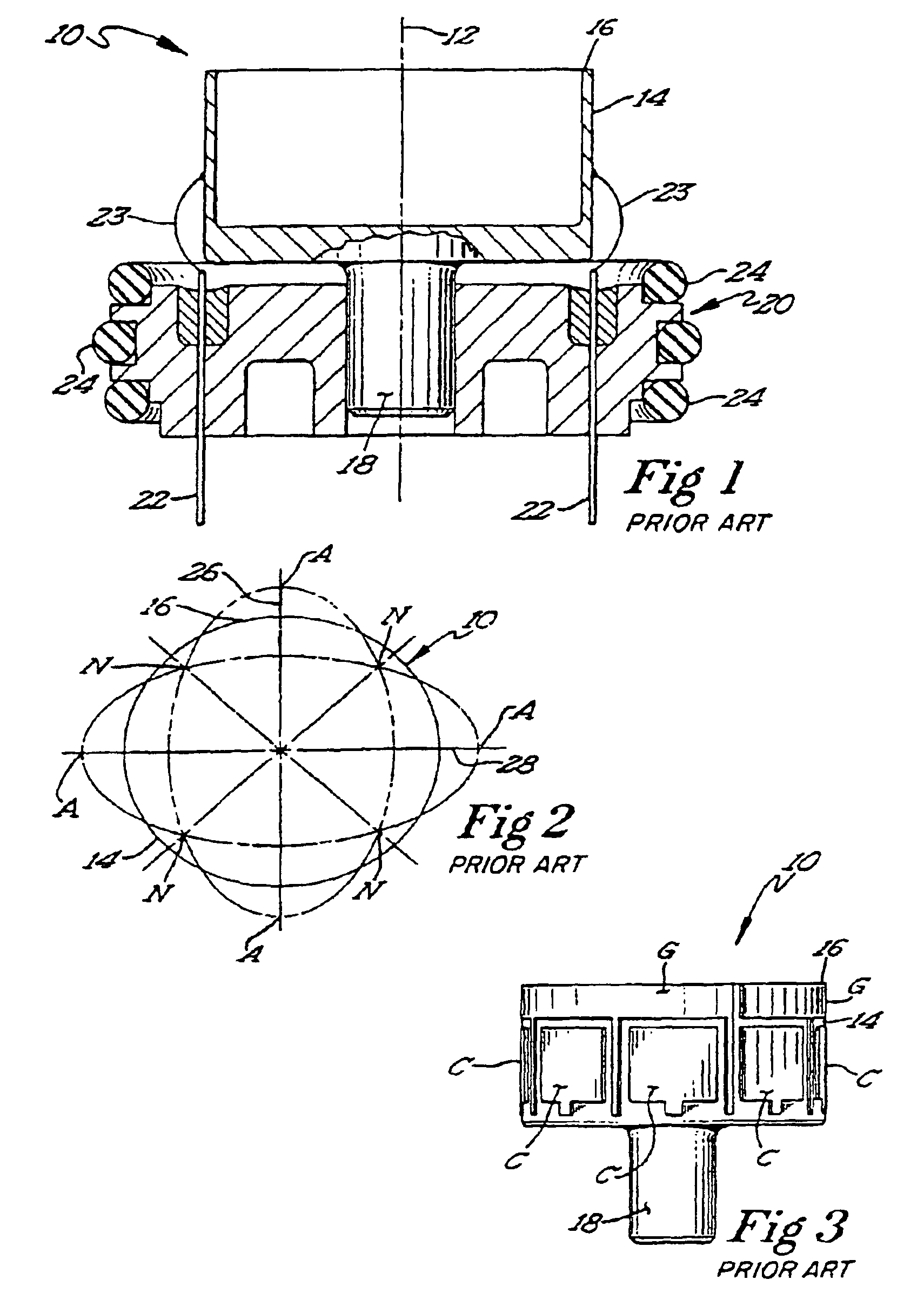

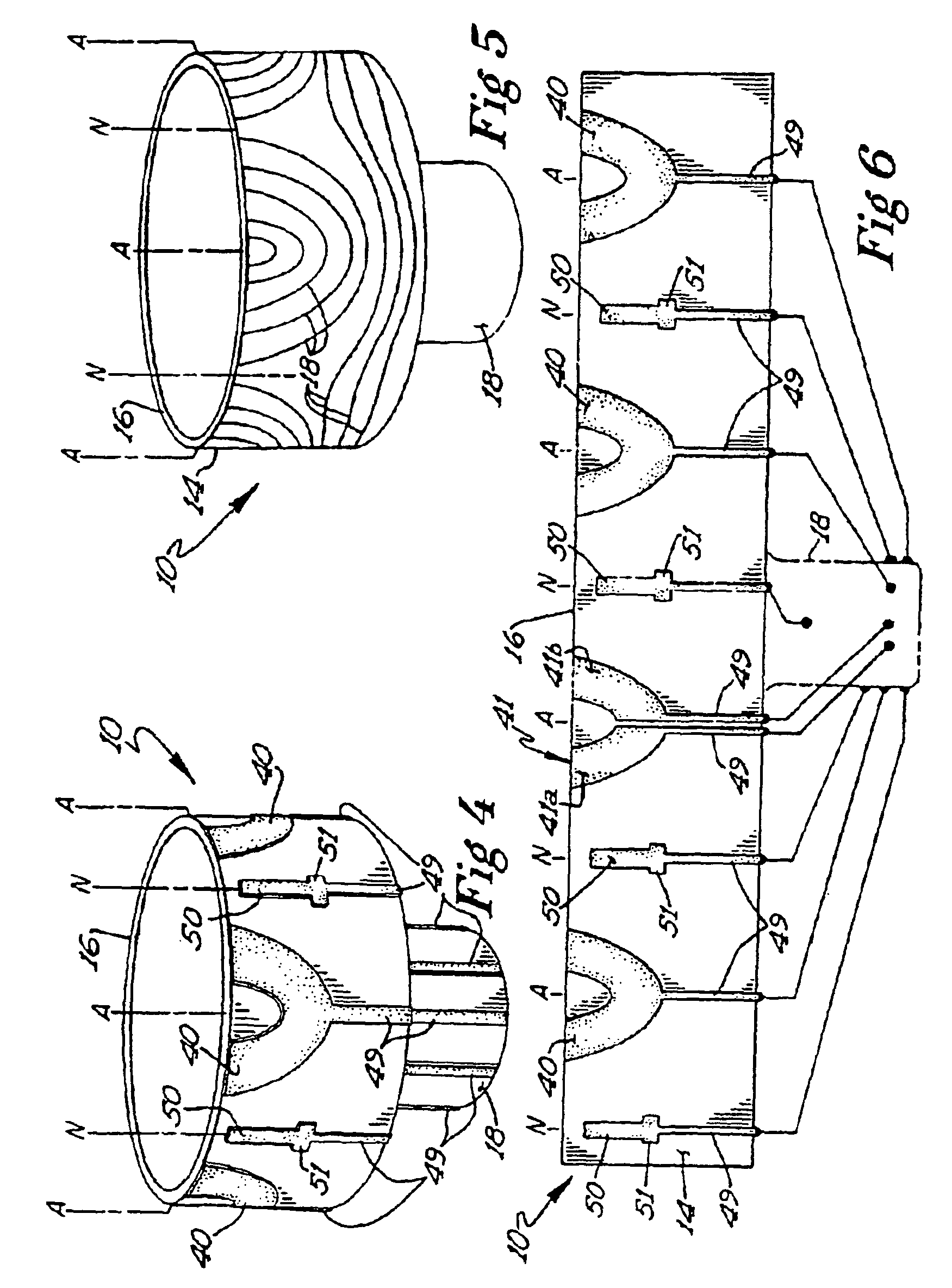

[0053]The preferred embodiment of the present invention may be used in conjunction with various types of resonating elements used in rate gyroscopes. However, the preferred embodiment of the present invention will be most fully described as applied to an axi-symmetric shell 10 such as the shell illustrated in FIGS. 1, 3-5a. Such a shell 10 may be caused to vibrate at a resonant frequency having a preferred mode of oscillation that is characterized by two nodal diameters (n=2) as illustrated in FIG. 2. It is to be understood that the improvements disclosed herein may have application outside of the specific embodiments described herein and are therefore not to be limited to just these embodiments.

[0054]Referring first to FIGS. 1, 3-5a, the shell 10 of the preferred embodiment is generally cylindrical and has an axis of symmetry indicated at 12. The upper portion of the shell 10 is a hollow cylinder having a relatively thin wall 14 with an upper edge 16. The lower portion or stem 15 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com