Conveyor oven having an energy management system for a modulated gas flow

a technology of energy management system and conveyor oven, which is applied in the direction of gaseous heating fuel, domestic stoves or ranges, furnaces, etc., can solve the problems of sharp increase in the cost of natural or propane gas for the burners, and achieve the effects of improving reliability, and reducing the cost of natural or propane gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

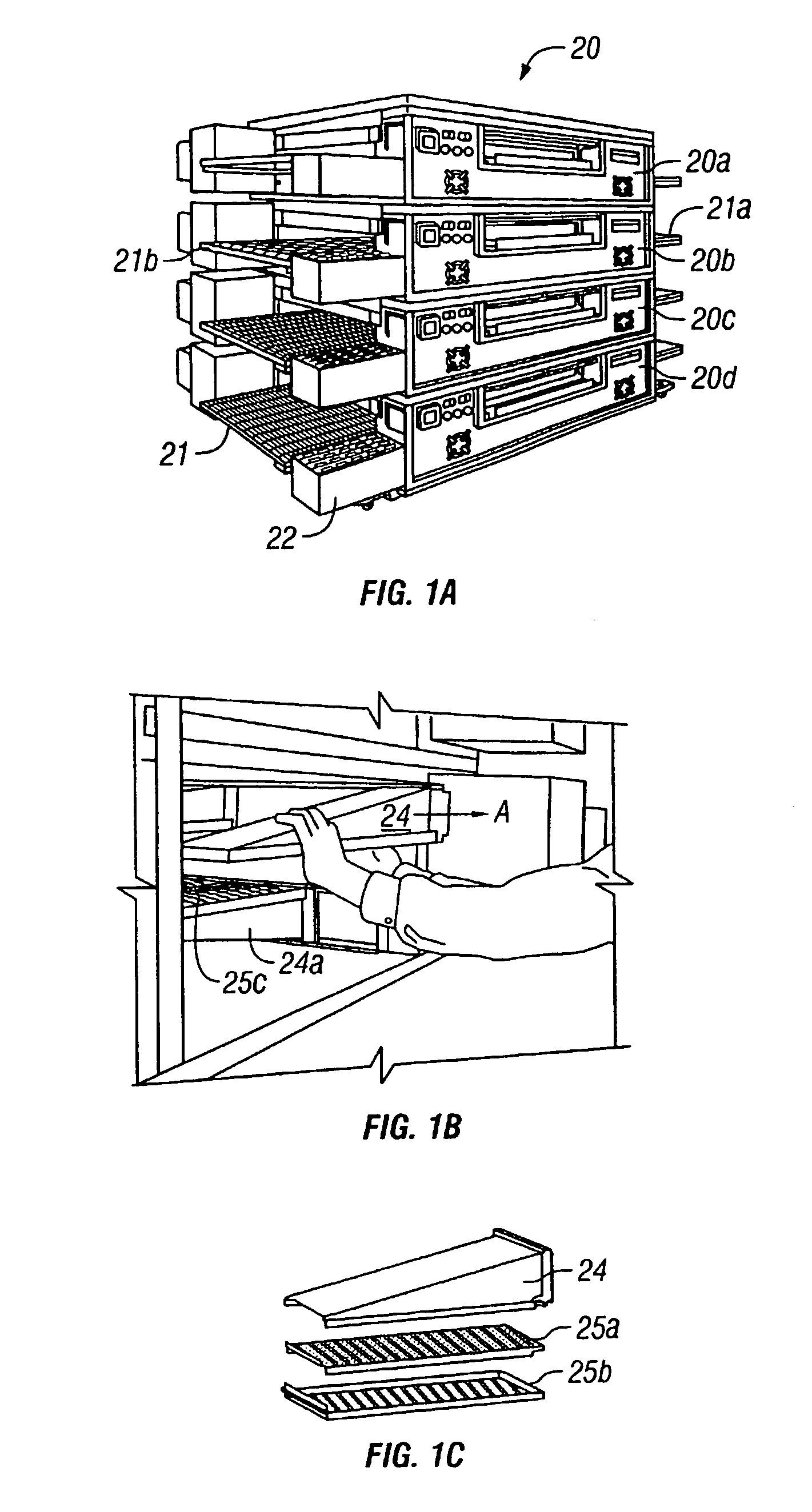

The equipment in FIGS. 1A–1C shows a conveyor for delivering a stream of heated air through an oven cavity. More particularly, FIGS. 1A–1C are perspective views of a conveyor oven 20 which receives a conveyor 21 (FIG. 1A) extending from an input end 21a through a cavity to an output end 21b of the oven. The motor for driving the conveyor is in the housing 22.

FIG. 1A shows a plurality of the ovens 20a–20b (sometimes called “decks”) stacked one on the other to increase the baking capacity without increasing the footprint dimensions. Each deck may be separately programmed to bake a different food product. FIG. 1B is a perspective view of a person removing a hot air delivery finger from an oven by sliding it in direction A along side rail tracks. FIG. 1C is a perspective view of the finger construction where two perforated plates 25a, 25b direct streams of hot air downwardly and onto the upper surface of a food product. Lower fingers 24a (FIG. 1B) direct hot air upwardly through perfora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com