Sacrificial anode assembly

a technology of anode and assembly, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of complex circuits, adversely affecting the appearance of the structure, and the power supply supplied with mains power can encounter power supply problems clearly, so as to maximise the efficiency of the system and reduce the amount of isolating means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

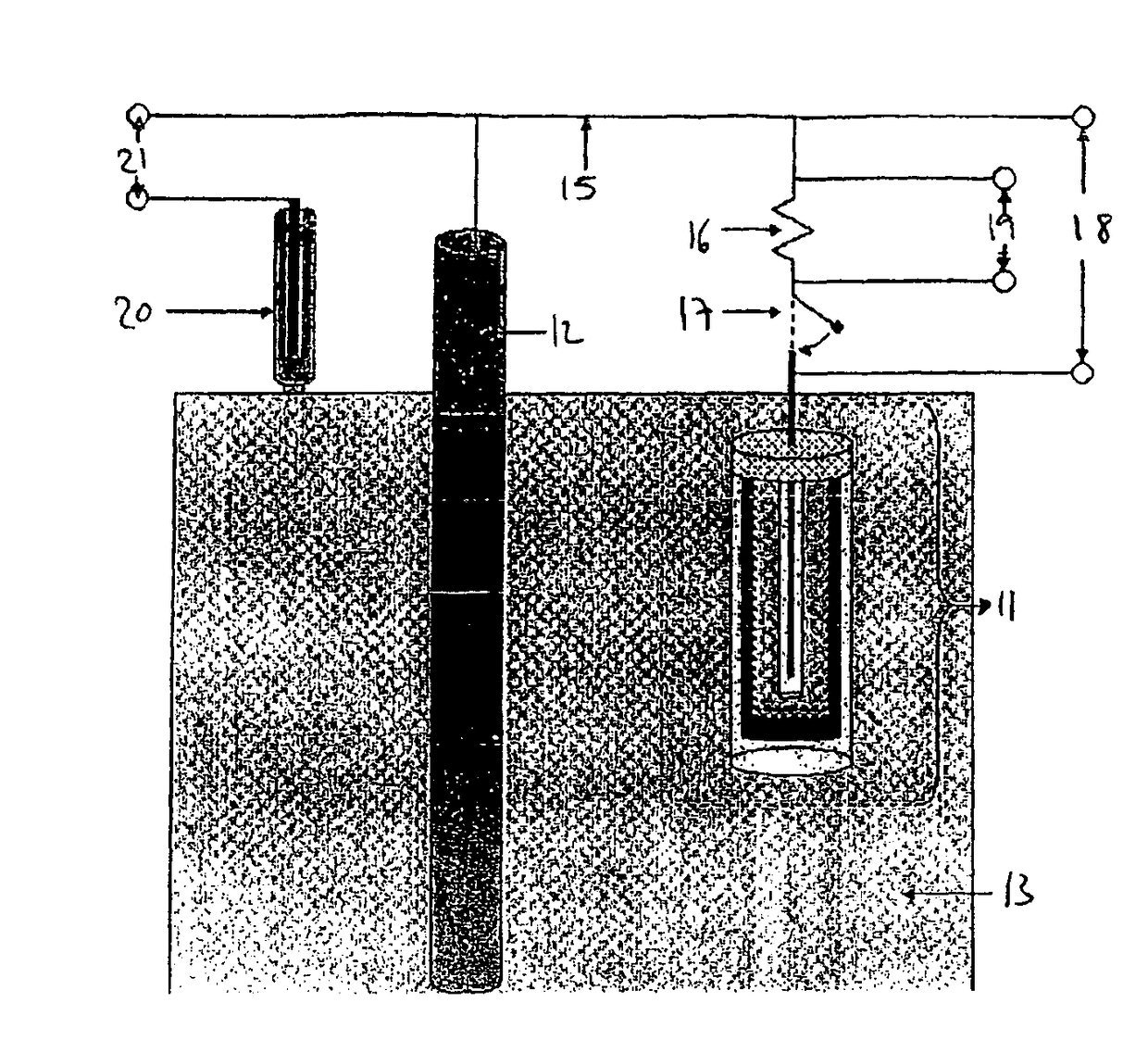

[0040]FIG. 1 shows a sacrificial anode assembly 1 for cathodically protecting a metal section. The assembly comprises a cell, which has an anode 2 and a cathode 3. The cathode 3 is a manganese dioxide / carbon mixture and is in the shape of a can, having a circular base and a wall extending upwards from the circumference of the base, so as to define a cavity. The anode 2 is a solid zinc anode of cylindrical shape, with the solid zinc being cast metal, compressed powder, fibres or foil. The anode 2 is located centrally within the cavity defined by the can shaped cathode 3 and is in contact with electrolyte 4 present in the cavity defined by the can shaped cathode 3, which maintains the activity of the anode. The electrolyte 4 is suitably potassium hydroxide, and may contain other agents such as zinc oxide to inhibit hydrogen discharge from the zinc. A porous separator 5, which is can shaped, is located inside the cavity 3a defined by the cathode 3, adjacent to the cathode 3. Accordingl...

example 2

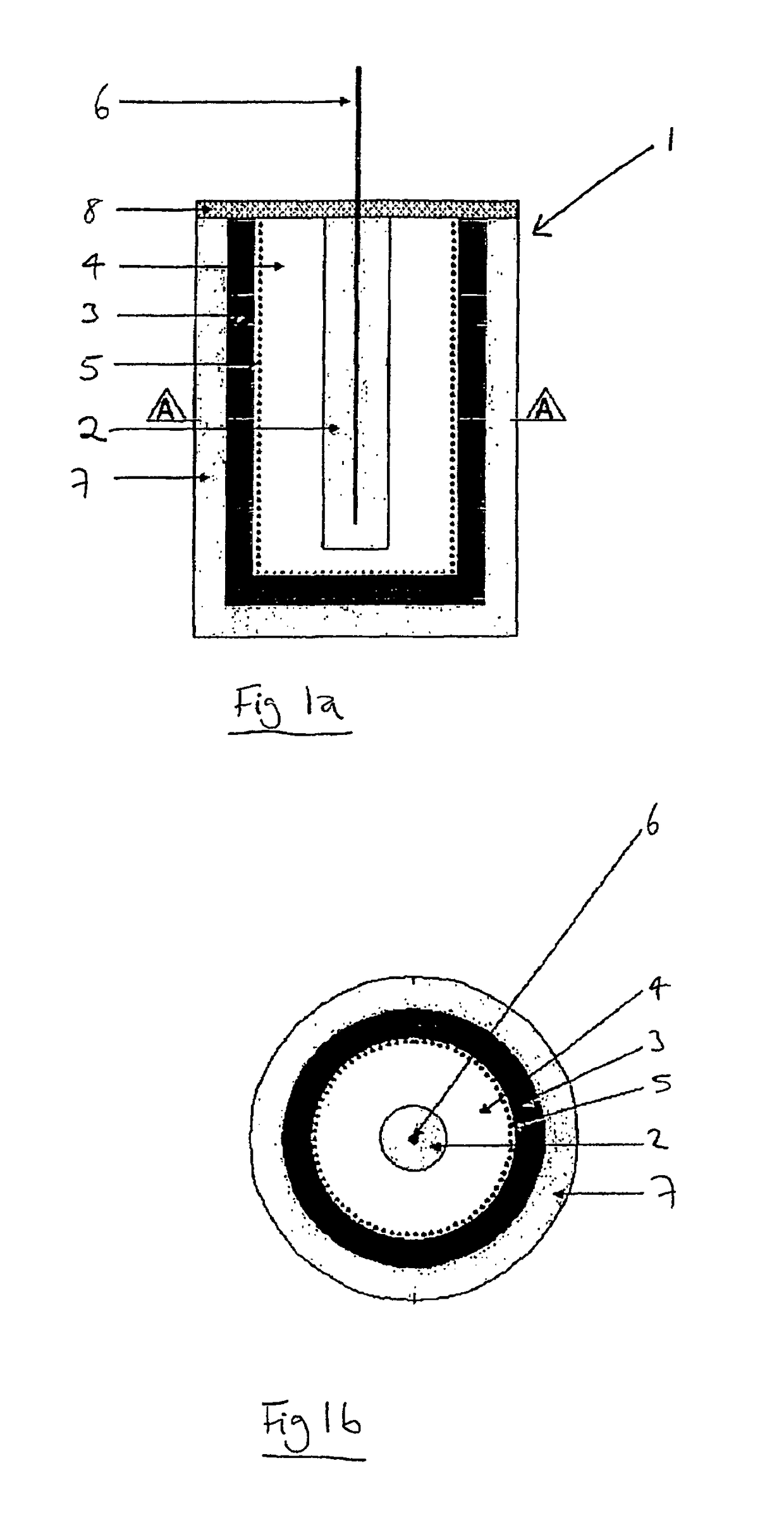

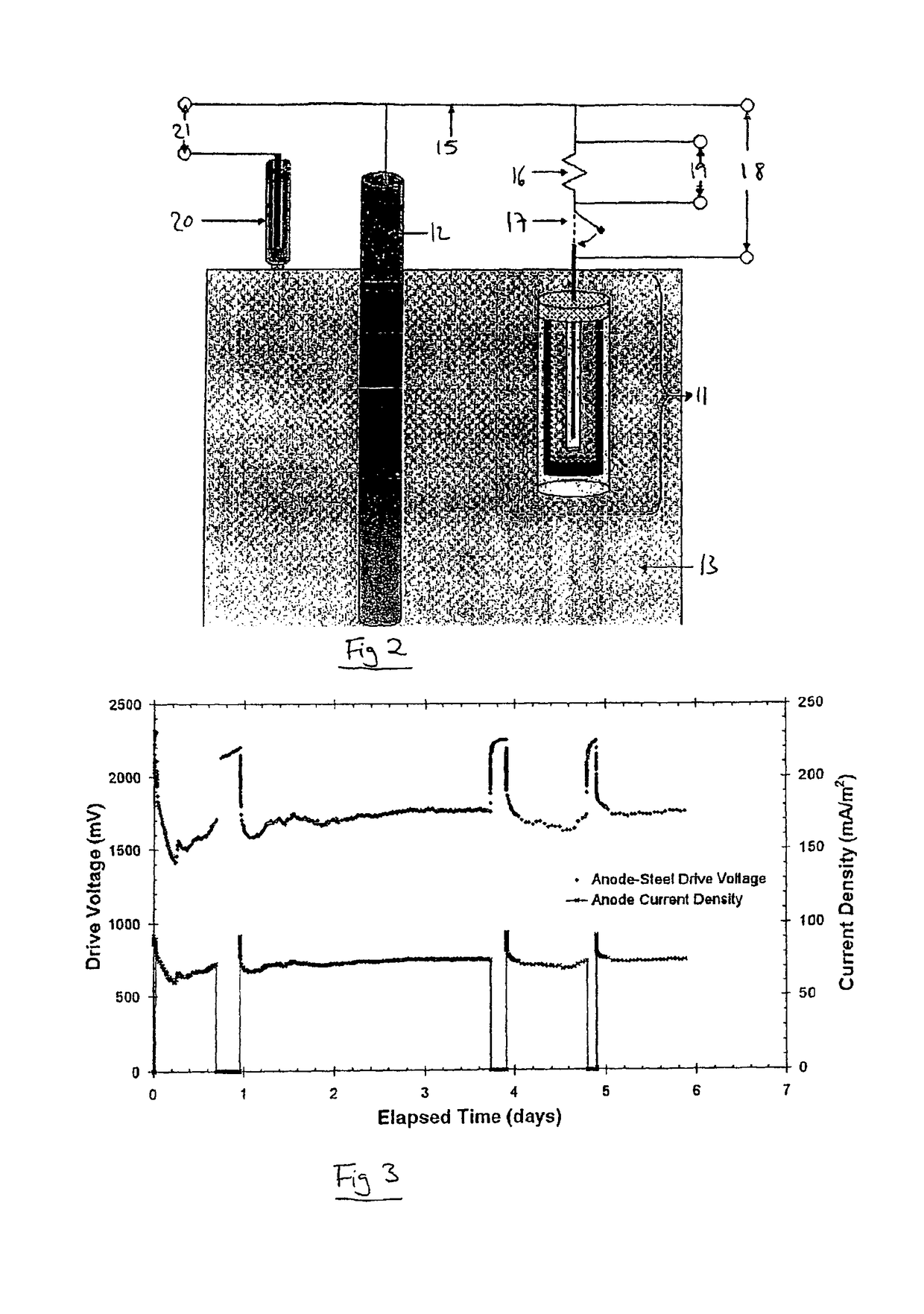

[0044]FIG. 2 shows a sacrificial anode assembly 11 connected to a 20 mm diameter mild steel bar 12 in a 100 mm concrete cube 13 consisting of 350 kg / m3 ordinary Portland cement concrete contaminated with 3% chloride ion by weight of cement.

[0045]The sacrificial anode assembly 11 comprises a cell, which is an AA size Duracell battery, and a sacrificial anode, which is a sheet of pure zinc folded to produce a zinc can around the cell. This zinc is folded so as to contact the positive terminal of the cell, and a conductor 14 is soldered to the negative terminal of the cell. A silicone-based sealant is located over the negative and positive cell terminals so as to insulate them from the environment.

[0046]Prior to placing the sacrificial anode assembly 11 in the concrete cube, potentials were measured using a digital multimeter with an input impedance of 10 Mohm, which showed that the potential between the external zinc casing and a steel bar in moist chloride contaminated sand was 520 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| driving voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com