Processing method for hydrophilizing body surface

A processing method and technology on the surface of objects, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of not being able to use for a long time, loss of surfactant, and easy peeling off of the film, so that it is difficult to distinguish, simple in method, and maintains hydrophilicity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below with reference to the drawings and specific embodiments.

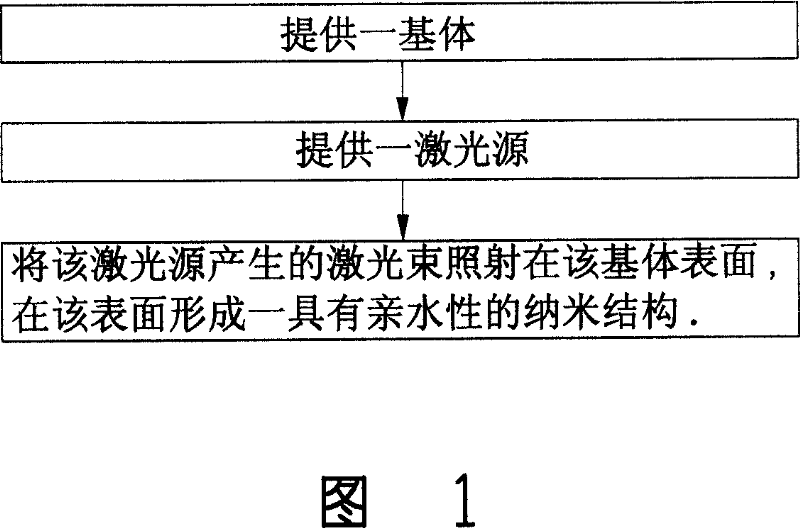

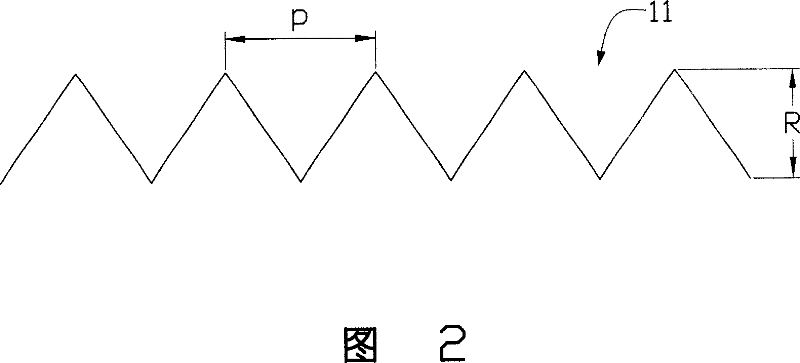

[0013] Please refer to FIG. 1. The present invention provides a processing method for making the surface of an object hydrophilic, which includes the following steps: first, a substrate to be processed to be made hydrophilic on the surface is provided, and the substrate material includes: glass, metal or alloy ; Provide a laser source, according to the different substrate materials, can use carbon dioxide laser to process the glass surface, or neodymium-doped yttrium aluminum garnet (Nd-YAG) laser to process the surface of metal and alloy; irradiate the laser beam generated by the laser source On the surface of the substrate, a hydrophilic nanostructure is formed on the surface. Among them, the method of processing with a laser source can refer to the currently known laser processing or laser engraving technology, that is, the high-intensity laser output from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com