Secondary packaging device of avalanche photodiode for infrared photodetection

An avalanche photoelectric and packaging device technology, which is applied in measurement devices, photometry, optical radiation measurement, etc., can solve the problems of increased temperature sensitive control of devices, difficulties, and restrictions on sealing materials, so as to reduce volume and heat capacity, and eliminate moisture. The effect of sensitive temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

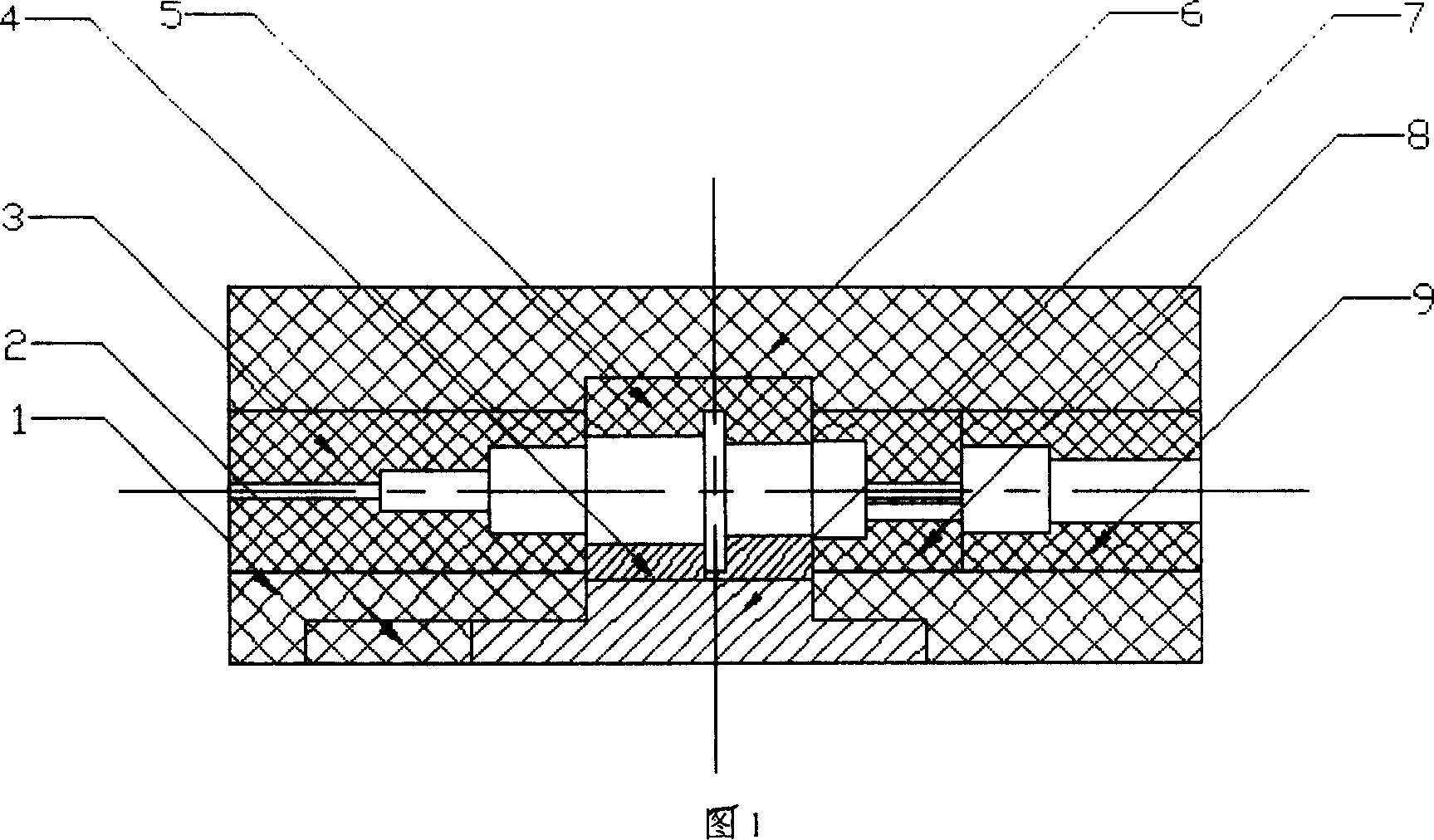

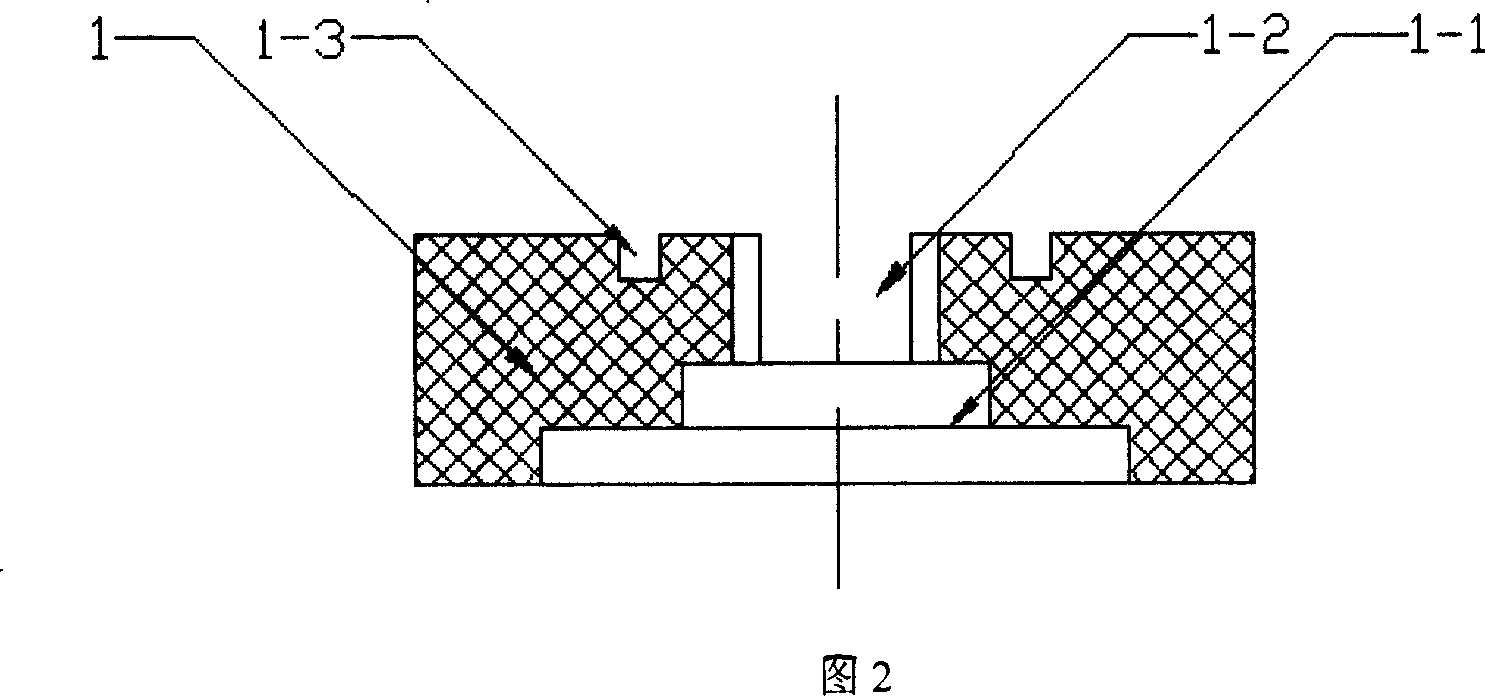

[0069] The structure of the present invention is shown in Figure 1-7, the bottom of the base 1 has a stepped groove 1-1, the upper end of the base 1 has a bottom groove 1-2 that runs through the left and right end faces of the base, and the bottom groove 1-2 is connected to the bottom surface of the base. Step grooves 1-1 communicate.

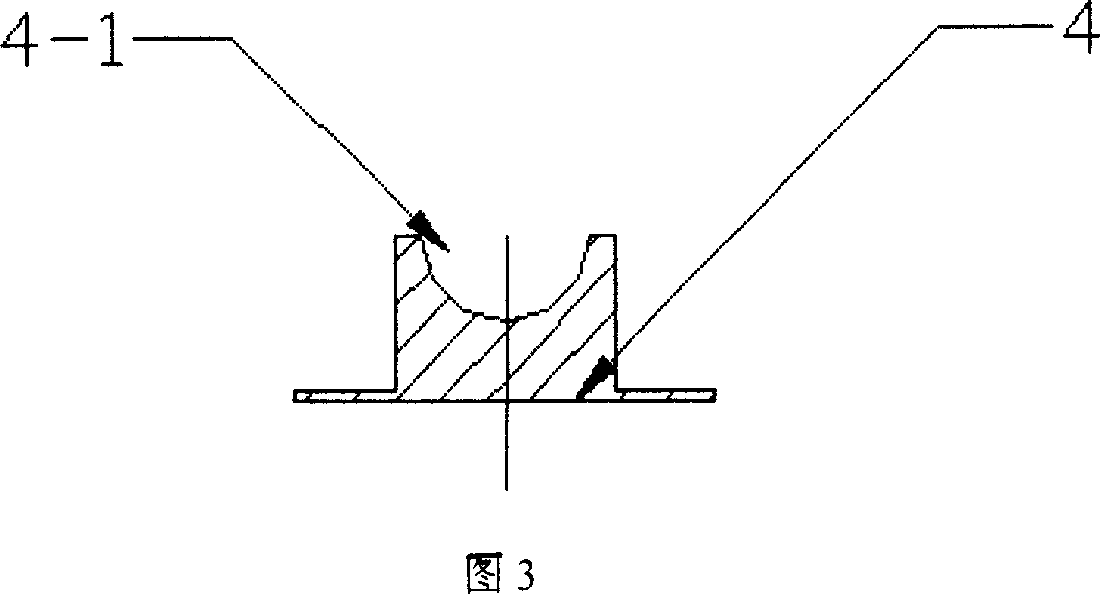

[0070] The bottom of the step groove 1-1 places the auxiliary cooling fin 4, the lower part of the auxiliary cooling fin 4 is in the step groove 1-1, and the upper part is in the bottom groove 1-2. The role of the auxiliary heat sink is to play an auxiliary heat conduction role between the avalanche photodiode device and the semiconductor cooling sheet.

[0071] Auxiliary heat sink 4 has an auxiliary heat sink groove 4-1 matched with the connecting flange of the avalanche photodiode device. Cylindrical groove.

[0072] The semiconductor refrigerating sheet 7 is placed in the step groove 1-1 close to the auxiliary heat sink 4, and next to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com