Process for treating yellow ginger saponin waste water by hydrochloric acid method

A technology for turmeric saponin and wastewater treatment, which is applied in water/sewage treatment, adsorbed water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as incompatibility, and achieve the effect of high removal rate and prolonged residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

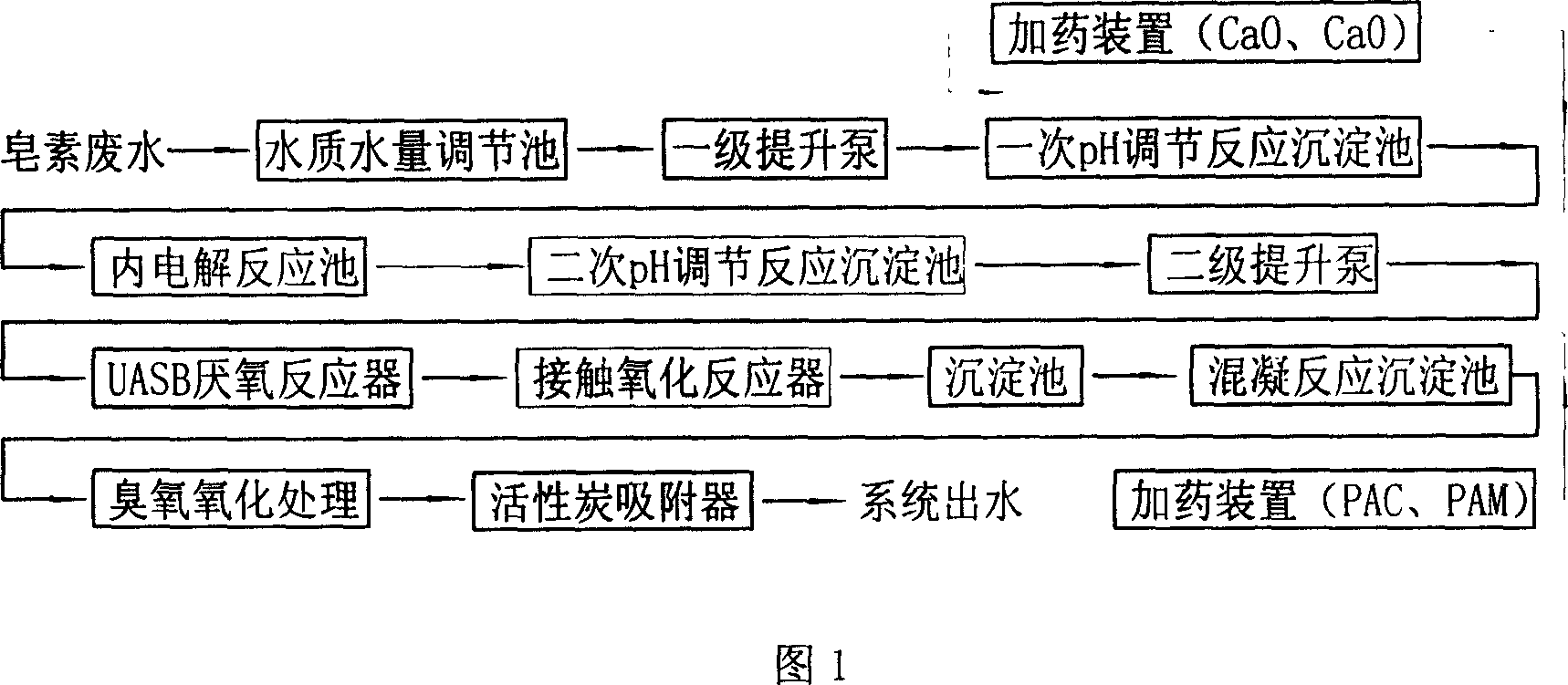

[0012] As shown in Figure 1, the technique of hydrochloric acid method turmeric saponin waste water treatment comprises the steps:

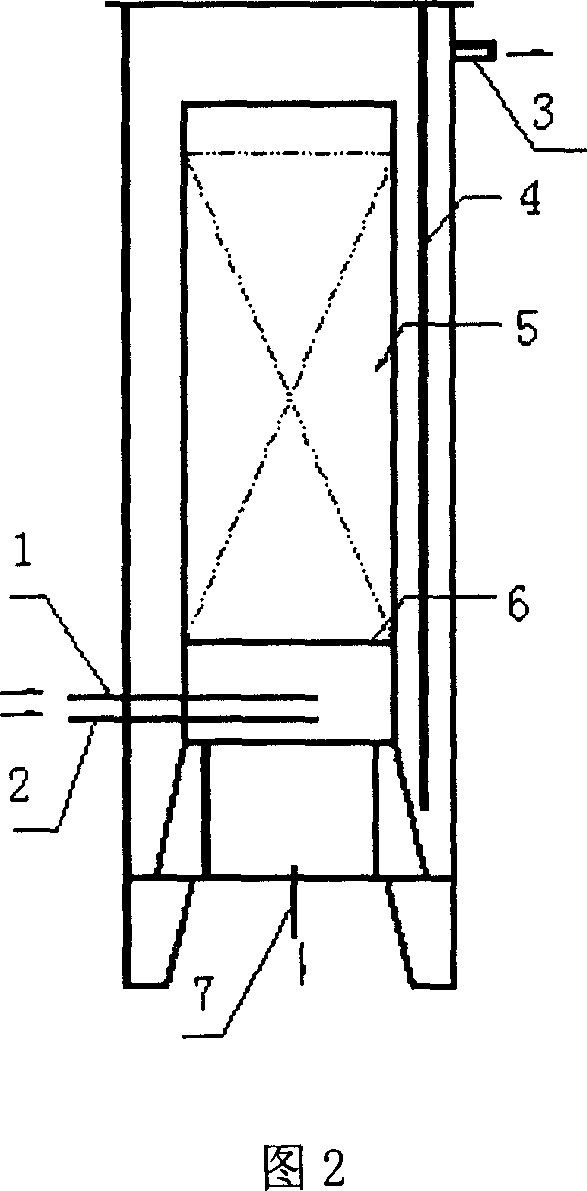

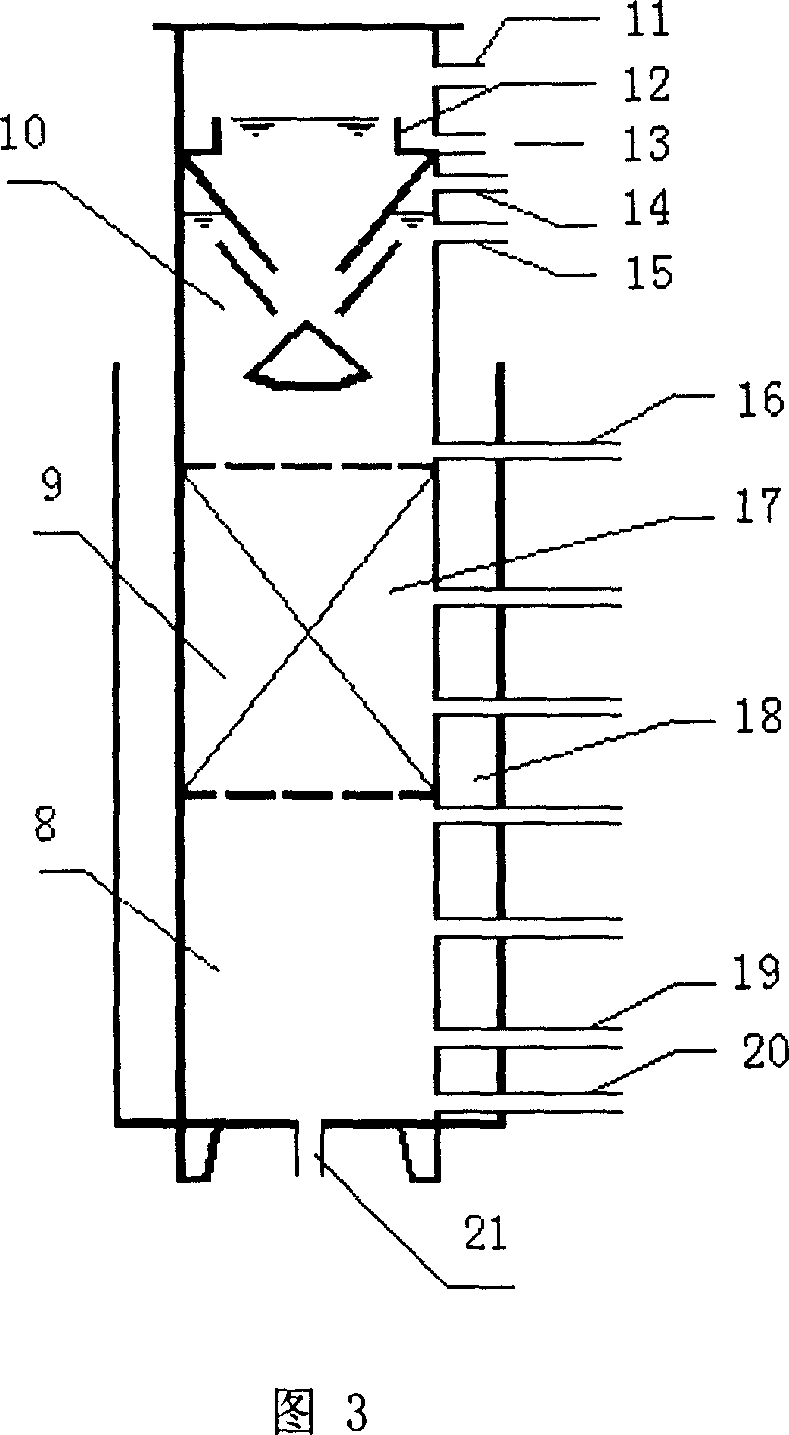

[0013] 1). The mixed waste water from the production of turmeric saponin by the hydrochloric acid method is first discharged into the water quality and quantity adjustment tank, and the residence time is 1-2 days; After 20% milk of lime, the pH value of the wastewater rises to 3.0-6.0, and the COD removal rate is 10-20%; 2). The effluent enters the electrolytic reactor in the aeration for pretreatment, and the electrolysis reaction in the aeration The device is filled with oxygen to remove part of COD and chroma, the removal rates are 10-30%, 20-40% respectively, and the pH value of the wastewater rises to 5.5-6.0; 3). After the wastewater is discharged from the internal electrolysis, it flows into the secondary Secondary pH value adjustment reaction sedimentation tank, adjust the pH value of waste water with CaO solution, make the pH value of wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com